Introduction

The course for introduction to the digital fabrication was floated in order to understand the relation between the machines and the computer data, how the algorithms used to create the forms in computer can be generated using specific fabrication techniques. The main focus of the course was oriented on the recursive geometry, starting with the base geometry which can be aggregated in all directions. Main techniques we are working on are Laser cutting, 3d printing & CNC Milling.

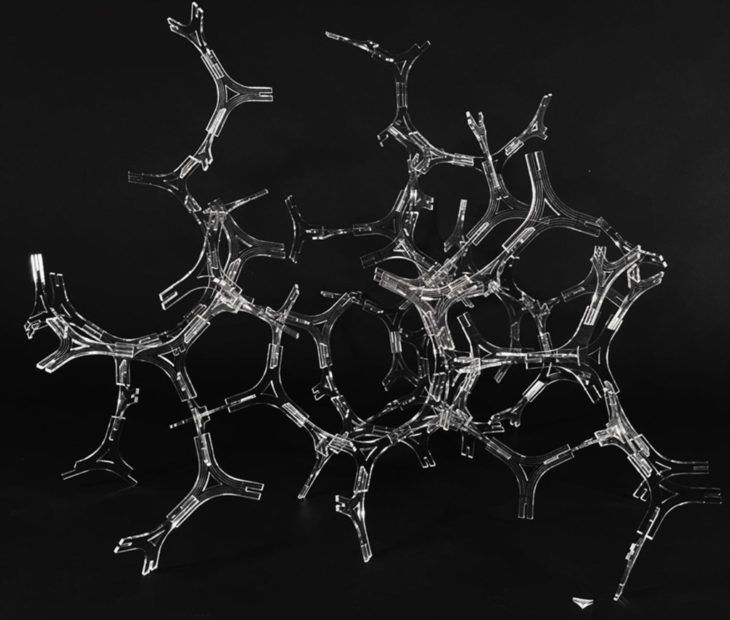

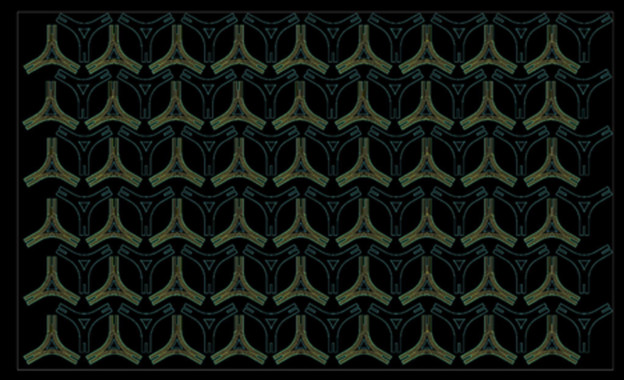

Laser cutting – Tri-nodular formulations

The criteria of design was to develop a recursive geometric form using laser cutting machine that can be manipulated with complex fabrication perspective. The concept that we had evolved is tri-nodal form with a base geometry that can recurse itself into a much complex polyhedral form based on the joining parameters. The material incorporated was 3mm transparent Acrylic board with interlockable joinery with specific tolerance setup as per the iterated tolerance markup of the interlockable parts.

Material: 3MM ACRYLIC

Machine: Epilog 50-75W

Workpiece Volume: 600X890mm

Total Pieces Cut: 96

Working Parameters

Cutting

Speed : 15

Power : 90

Frequency : 5000

Engraving

Speed : 100

Power : 5

Frequency : 5000

Total Cut Time: 1h 16 min

The Module had been incorporated engraving on tween lines that would be the face of the overall recursive module.

Aggregation Process:

Process:

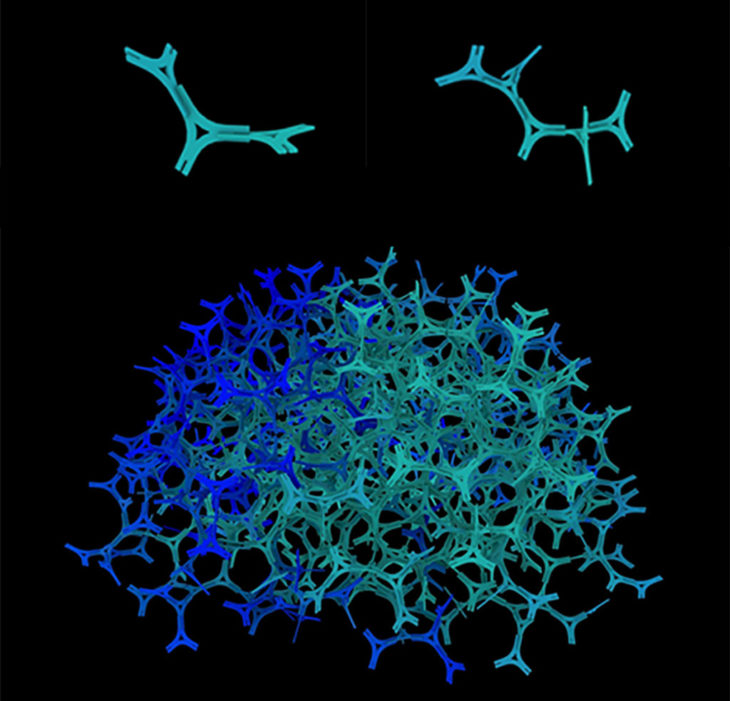

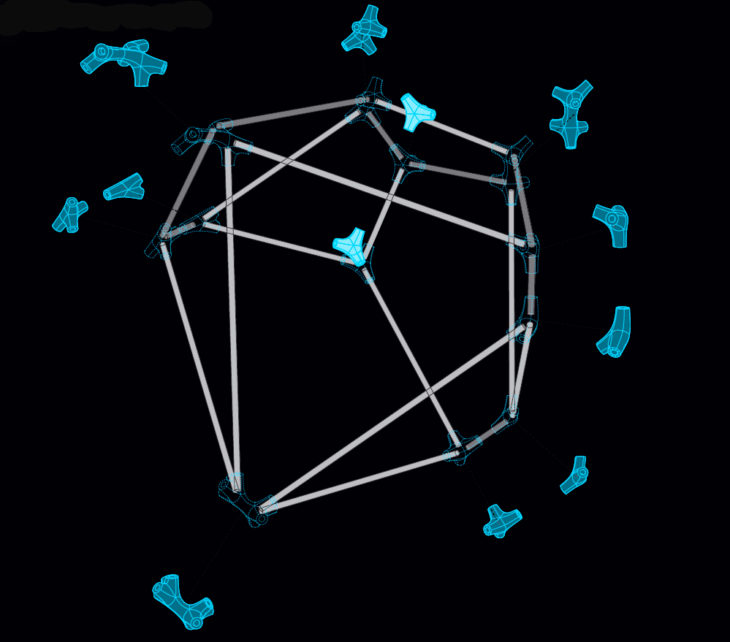

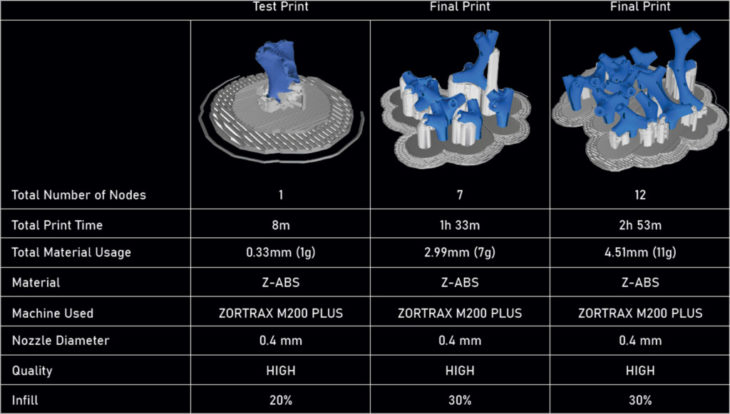

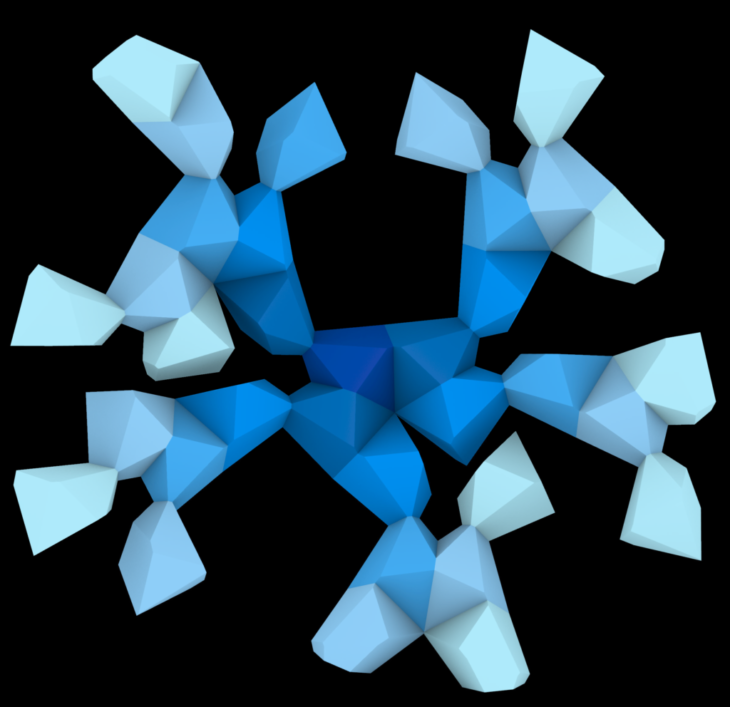

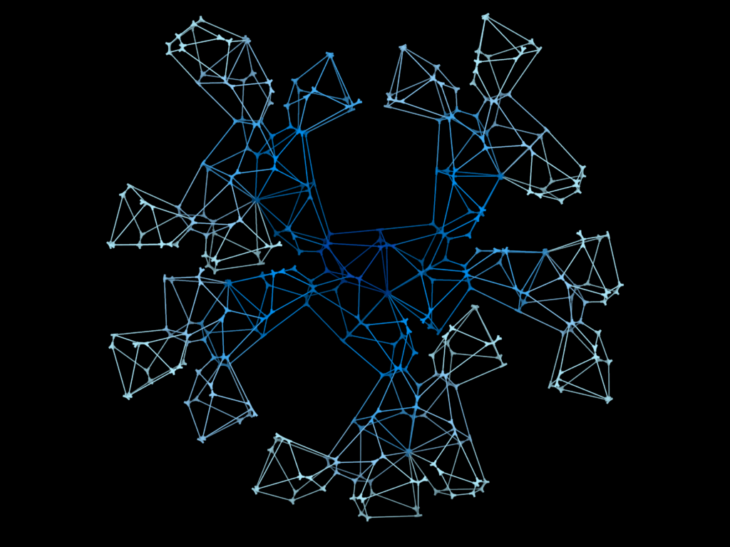

3D Printing – Modular Growth

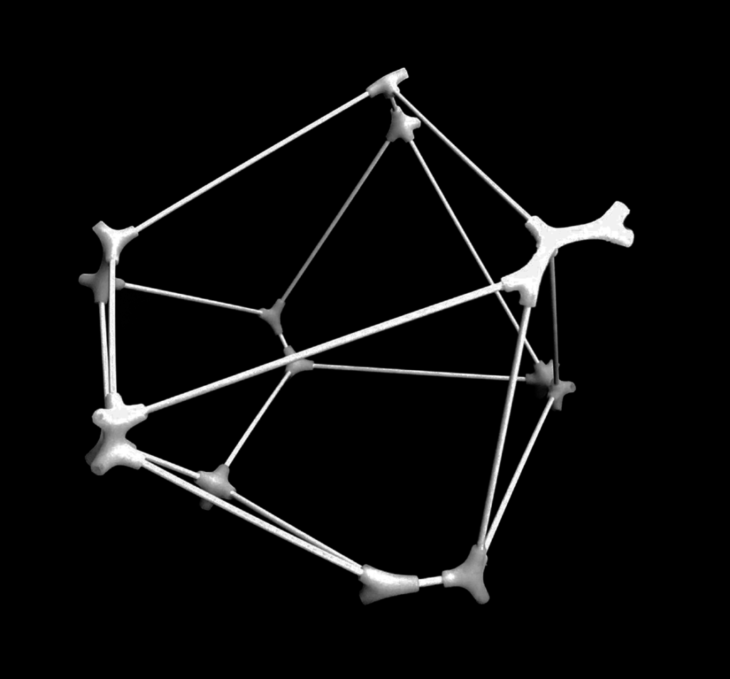

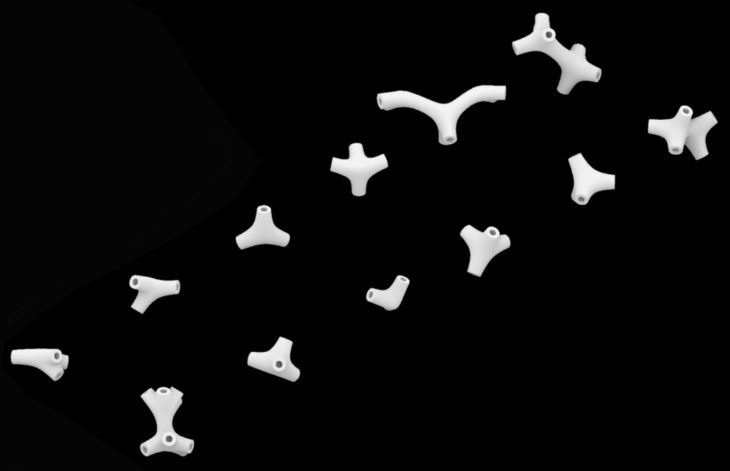

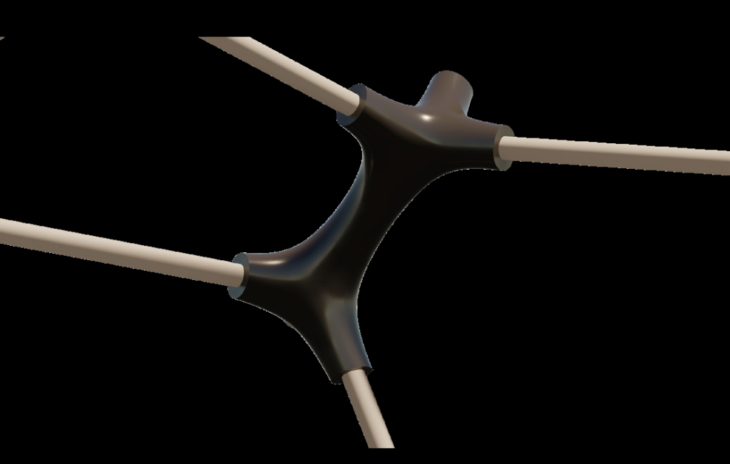

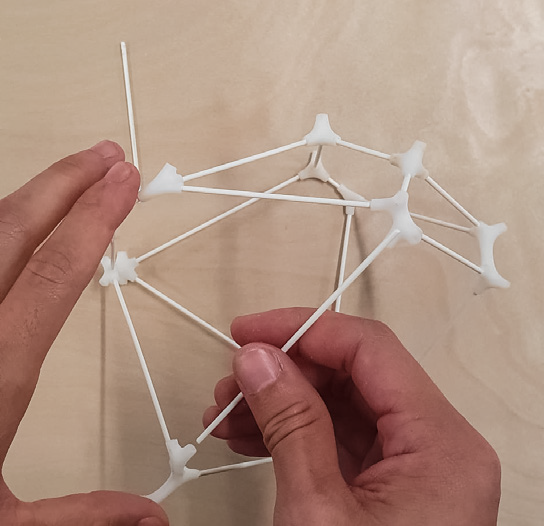

The concept was to create a polymorphic non identical nodal form with multidimensional aggregate form in three of the faces.

The nodes that share the same face within the shape are mirrored to create new attachments to continue the recursive

geometries.

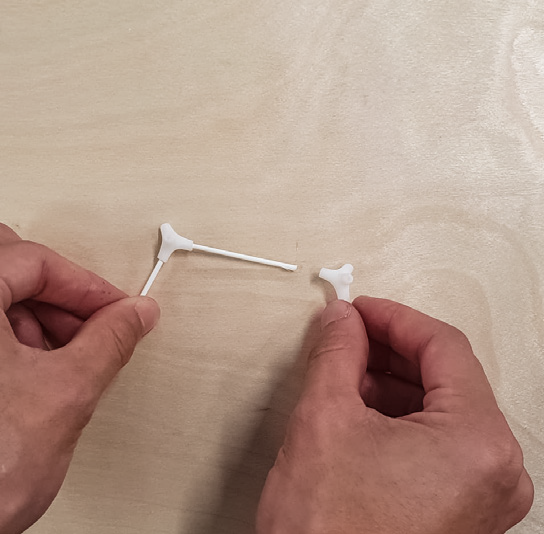

We observed a constrain in printing a specific node as the support anticipated was not sufficient but later on we rectified it on the other node prints

Nodes

The overall form has 12 different nodes developed as per the overall geometry.

Working Parameters

Aggregation Process

Assembly

CNC

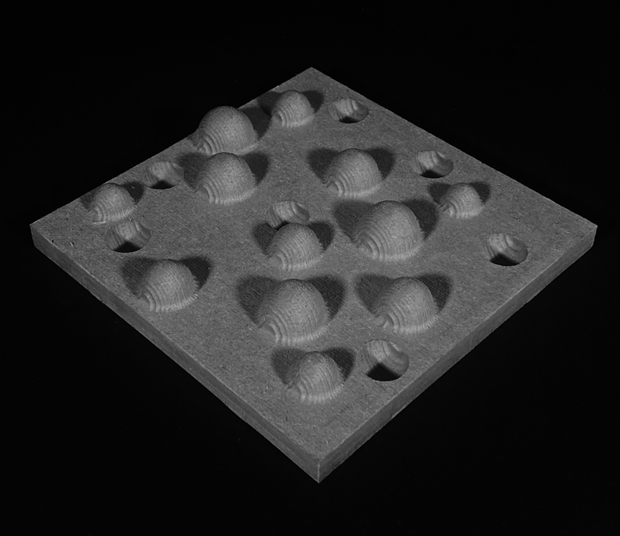

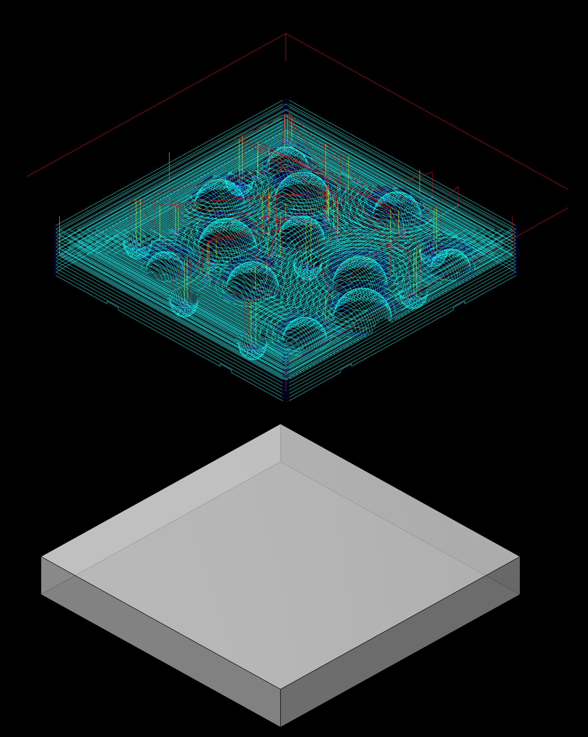

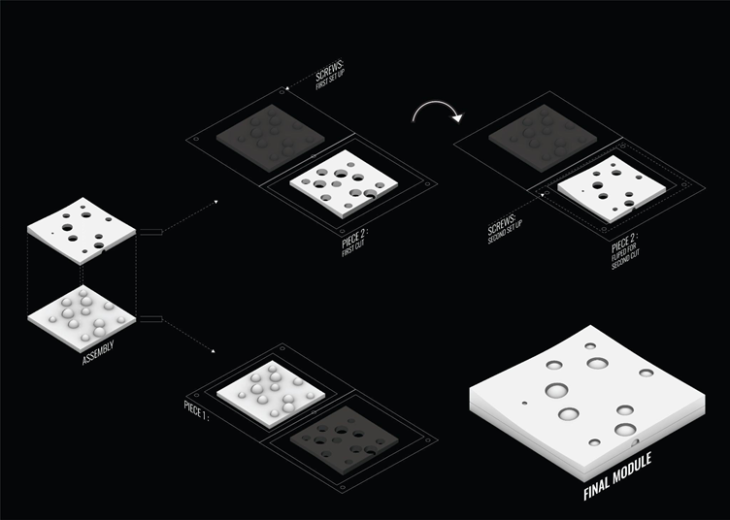

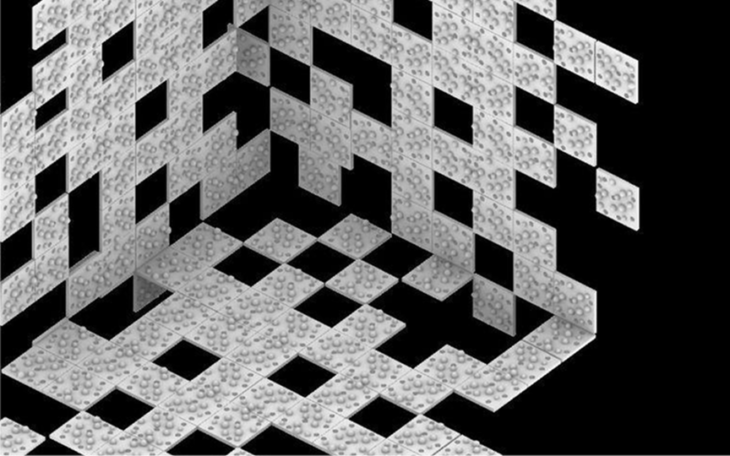

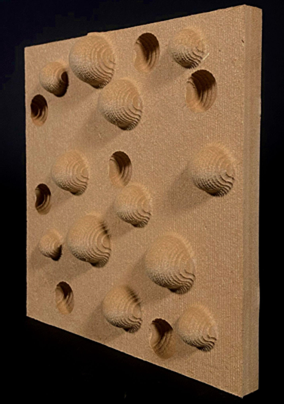

The CNC milling project concept was evolved from the natural recursive geometric sphere formulations in terms of crest and trough differentials of moulds on surface. The aim of the milling project was to achieve a flat extruded geometry with spheres. The shape can be replicated and iterated in three axis to form the final recursive output.

RhinoCam parameters:

Material: MDF

Machine: T-Rex(P59)

Post Processor:CNC_STEP_BCN

Workpiece volume: 320x320x40mm

Horizontal Roughing

Flat Mill

Diameter: 10

Spindle Speed: 12000

Cut Direction: Upcut

Stepdown Control (dZ):50%

Stepover Distance: 40%

Total mill time: 25.5minutes

Parallel Finishing

6mm Ball mill

Diameter: 6mm

Spindle Speed: 12000

Cut Direction: Upcut

Stepover Control: 25%

Total mill time: 15.8minutes

2 ½ Axis Profiling

Flat 6mm

Diameter: 6mm

Spindle Speed: 12000

Cut Direction: Upcut

Total mill time: 5.7 minutes

MILLING PROCESS

Aggregation:

Final Product

Introduction to Digital Fabrication – Recursive Geometries

Students: James Kingsley Claudin, Diego Vazquez Santos, Neslihan Gulhan

Faculty: Ricardo Mayor, Lana Awad, Shyam Francesco Zonca