iPod Nano 2nd Generation

As part of the Fab City Design Strategies course, we were asked to understand the various factors that contribute to the production of the products we use in our every day life, by researching their true origins. Where they were made, who contributed to their production, what materials were used, where these materials were extracted from etc. In this case, a 10 year-old iPod Nano was disassembled in order to map its production process.

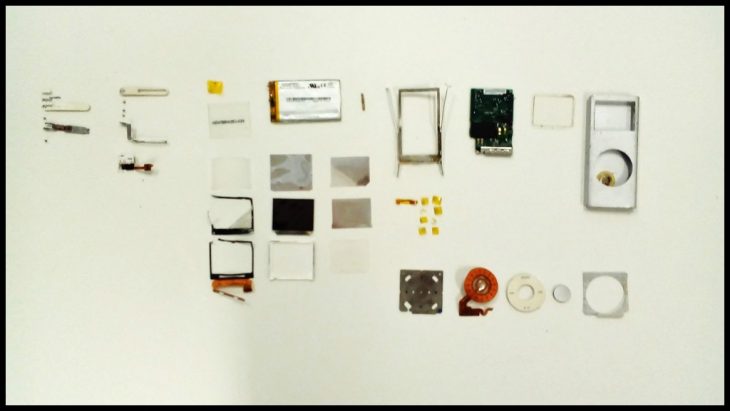

iPod Nano Disassembled

At least 45 different parts were extracted, most of which were aluminium, plastics and the main circuit board. Its various components were arranged and then categorized based on their material and function. The following materials were used for its production:

Some interesting components that were torn down, were the monitor, the track wheel and the main circuit board. The iPods monitor was comprised of 9 different layers including the Liquid Crystal monitor.

Disassembly of the iPod’s monitor.

The track wheel, was comprised of 6 different parts, plastic or aluminium.

Track Wheel Disassembled

The most interesting part, was the main circuit board on both sides of which were attached different chips. Those chips were apparently produced by different manufactures and then assembled in China. The real names of the manufacturers of the chips can only be speculated, due to specific transparency policies that Apple holds when it comes to disclosing valuable information about its collaborators.

Left-Front Side/Right-Back Side

In the picture above, can be clearly seen different chips and components the vast majority of which were produced in different places around the world and assembled in the factories of Foxconn, China. Through a series of speculations the following list emerges:

1)Docking Connector-FOXLINK-China

2)Flash Memory-TOSHIBA-Japan

3)ARM Processor(the one with the Apple logo)-SAMSUNG-Korea

4)Audio Codec Chip-WOLFSON-UK

5)Power Control Chip-LINEAR TECHNOLOGIES-USA

6)USB Battery Charging-LINEAR TECHNOLOGIES-USA

7)Stepdown Switching Regulator-NATIONAL SEMICONDUCTOR-USA

8)IC Interface Controller-CYPRESS SEMICONDUCTOR-USA

9)Nor-Boot Flash-SILICON STORAGE TEC-USA

Here’s a short video of the disassembly process:

iPod Disassembly is a project of IaaC, Institute for Advanced Architecture of Catalonia

developed at Master in City & Technology in 2016-2017 by:

Student: Alex Mademochoritis

Faculty: Tomas Diez, Mathilde Marengo