Concept

This project is exploring a system which could make exhaustive use of the fabrication equipment, while efficiently maximizing the production process and final element. It pursues an assembly type made by clay that could be flexible as an exterior partition wall or rain / sun screen for a building envelope.

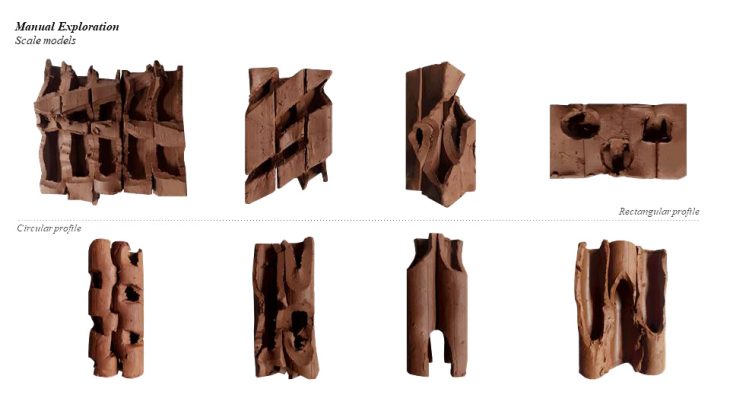

Manual Exploration

The aim of the manual exploration was the understanding of the characteristics of the material and in the same time the potential of wire cutting in shaping clay. The scale models where used to explore the general form of the system rather than its details.

Manual Exploration: Scale models

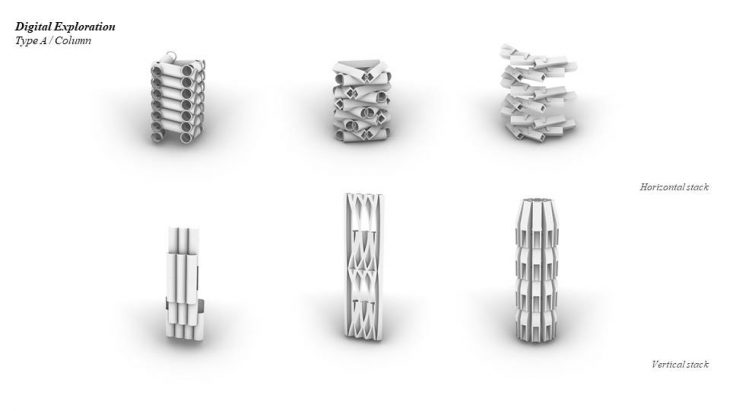

Digital Exploration

The digital exploration can be divided in two categories: columns (type A) and walls (type B). In each category both horizontal and vertical stacking of the profiles where investigated, in order to explore different results depending on the positioning of the unit.

Digital Exploration: Column (Type A)

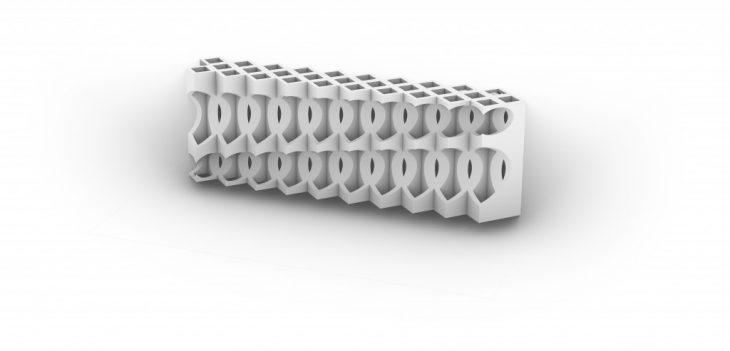

Digital Exploration: Wall (Type B)

The Proposal

The proposal is consisted of three rows of uniquely perforated rectangular profiles. The perforation of the profiles changes depending on where they are placed. The exterior units have larger holes, contrarily to the ones that are placed in the interior row, which have smaller holes.

Final shape

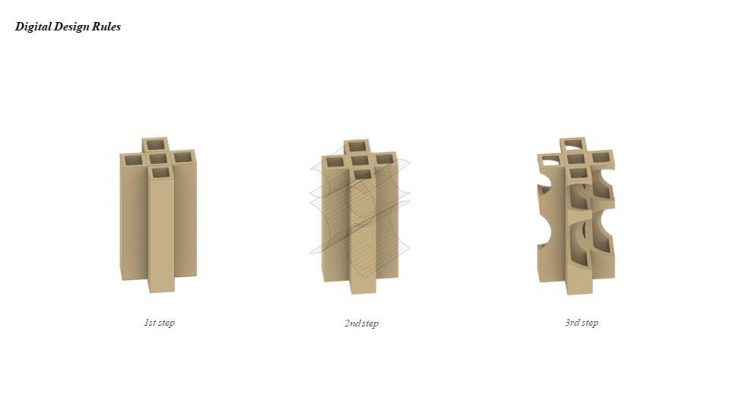

Digital Design Rules

Climatic Behavior

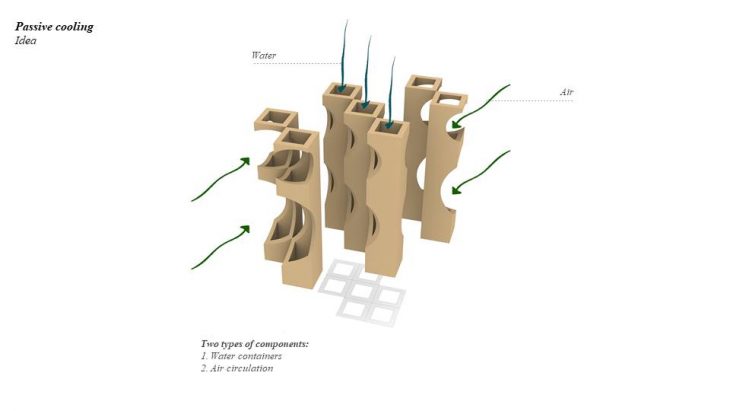

The first aim of the project was to create an air screening wall. The initial idea was to have two exterior rows that help the air flow through the wall and one row in the middle which will be used as a water container.

Passive cooling: initial idea

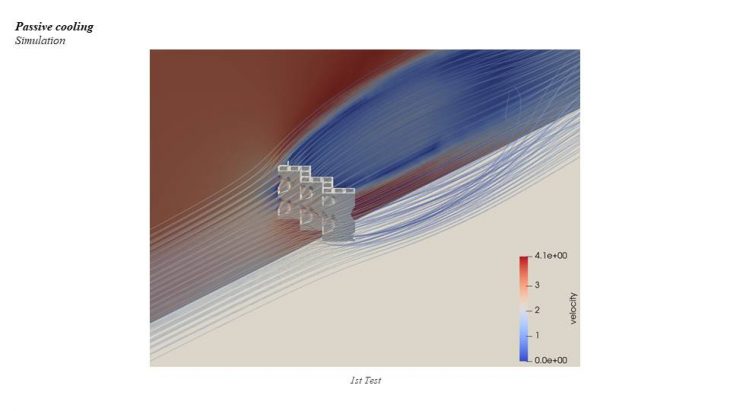

However, using CFD analysis the performative action of the element was evaluated and the design was re-informed after locating its failing points. The analysis proved the initial hypothesis to be incorrect, due to to the low amount of horizontal air passageways.

CFD simulation

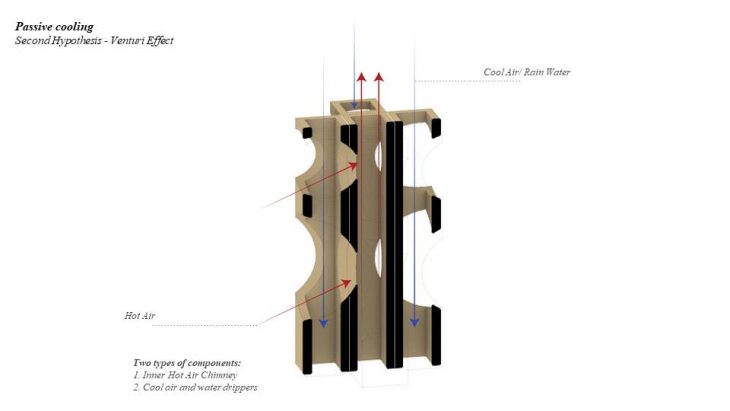

Building on this conclusion, the piece was redesigned to create a Venturi effect. The central pieces, being mildly perforated and stretch to the top of the wall, are pulling hot air from the surrounding environment and circulating cold air. In addition, water dripping through out the central pieces act as a secondary cooling mechanism. The second layer, being highly perforated, creates turbulence increasing the pressure and helping lower the overall temperature.

Passive cooling: 2nd hypothesis

Fabrication

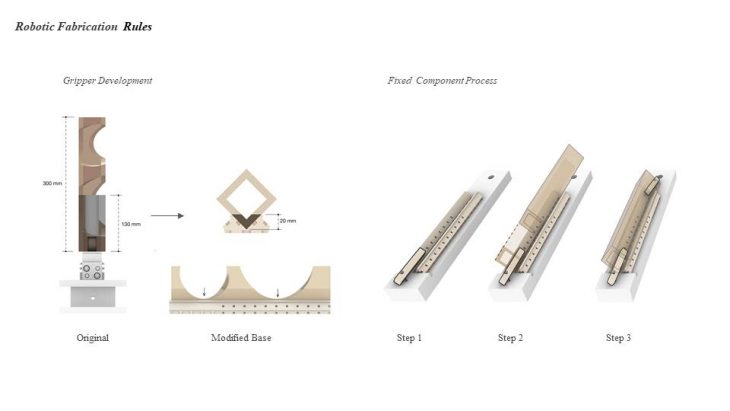

To achieve the desired result and facilitate the fabrication process, the original base used in the lab had to be modified. Instead of placing the component vertically, the new base was designed to let the component be placed horizontally with a rotation of 45 degrees.

Even though this approach has inherited limitations from the base, it allows cutting deep slices and ensures that the fabrication process is more stable.

Fabrication tools

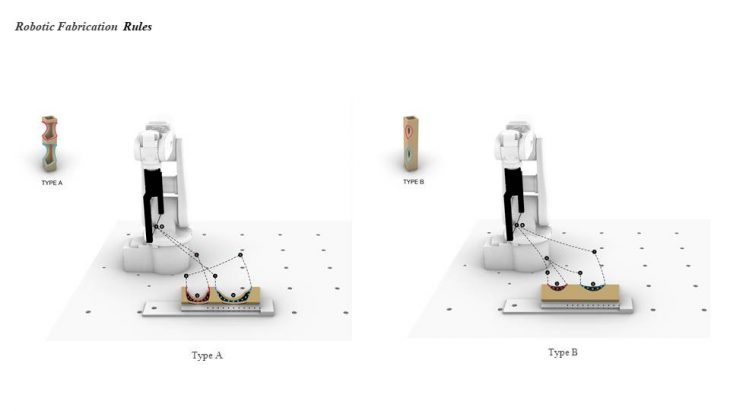

This design has two types of robotic tool paths: Type A and Type B.

While Type A has two holes in only one side, Type B has 4 small (2 in each side). That means that the components need to be flipped manually in order to achieve the final result.

Robotic simulation

The main challenge of the robotic fabrication in this case is the softness of the clay. Thus, the cutting speed needs to be checked during the process. Manual assistance is also needed, in collaboration with the robot, to ensure the stability of the components during the fabrication.

Even though each piece of the proposal is unique, the total fabrication time was only 45 minutes. While the fabrication was being done by a robot, the assembly was being done manually.

Fabrication process (photo: Orestis Pavlidis)

Final Prototype

Architectural Application

Architectural application (example)

IthaCut: Robotic wire cutting clay is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at Master in Robotics and Advanced Construction Workshop 1.1 in 2020/2021 by:

Students: Shahar Abelson, Charng Shin Chen, Michael DiCarlo & Alexandra Timageni

Faculty: Kunaljit Chadha

Faculty Assistants: Anna Batallé Garcia, Soroush Garivani, Ashkan Forughi Dehnavi

In collaboration with: Toni Cumella / Ceramica Cumella

Supported by: Ant Studio, Altair

Workshop Participants: Shahar Abelson, Hendrik Benz, Alberto Eugenio Browne Cruz, Charng Shin Chen, Michael DiCarlo, Helena Homsi, Arpan Mathe, Juan Eduardo Ojeda Valenzuela, Orestis Pavlidis, Aslinur Taskin, Alexandra Timageni