INTRODUCTION

This series of projects were enacted to explore various fabrication techniques that take digital information and translates them into the physical realm. The goal of each project was to develop a piece that circulated around geometries that could be repeated and compiled into various configurations of shapes. Along with the development of these projects the limitations of the techniques were pushed to see how far the design could be pushed.

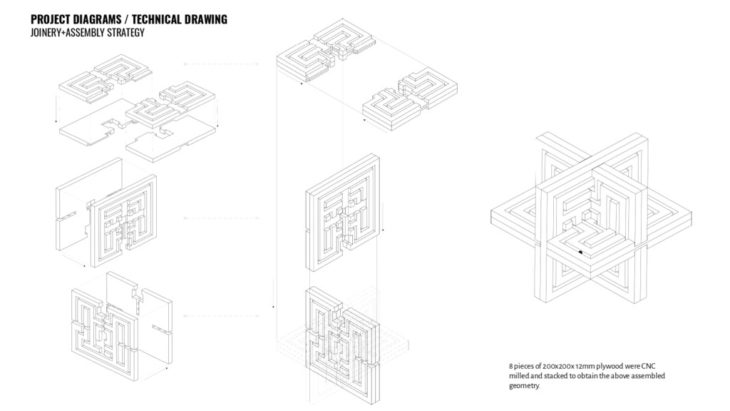

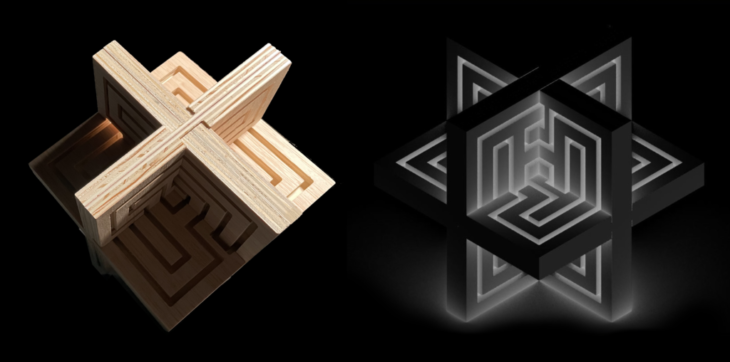

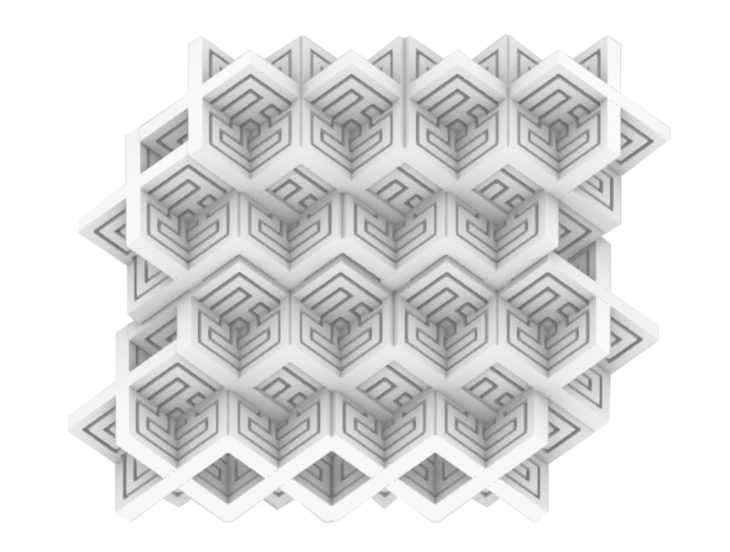

INFINITE LABYRINTH

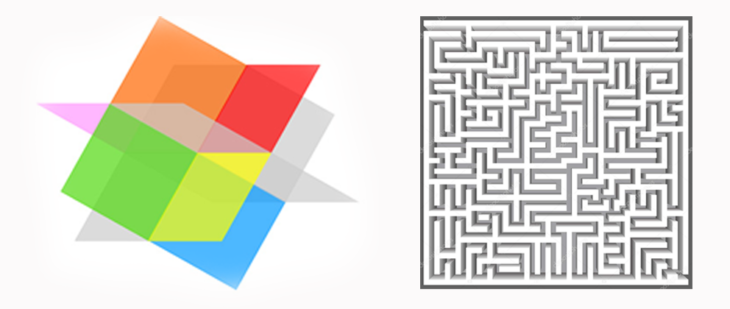

The Infinite Labyrinth is an experiment in CNC fabrication. CNC is a two-axis machine that is mostly limited to creating 2.5D projects. Challenging this limitation Infinite Labyrinth combines joinery techniques and two-axis cuts to produce a fully functional maze, usable in all orientations.

Intersecting Planes

STRATEGY

Material: Plywood – 12mm

Machine: T-Rex

PostProcessor: CNC_Step_BCN

Workpiece Volume: 200 x 200 x 200 mm

- Pocketing | Used after applying the engraving function to help prepare guides on the stock for placement of screws.

- Inner Profiling |

- Outer Profiling | 2 Bridges of 3mm depth and 4mm length per piece was used.

FINAL

Aggregation

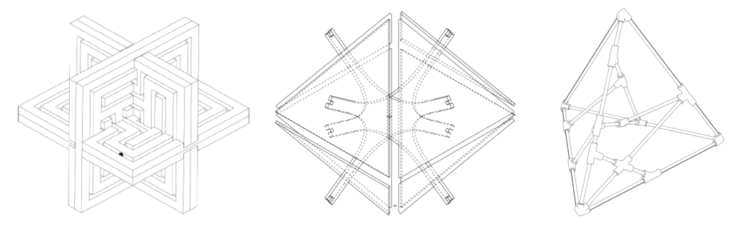

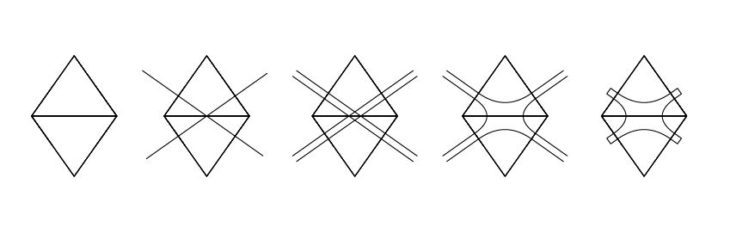

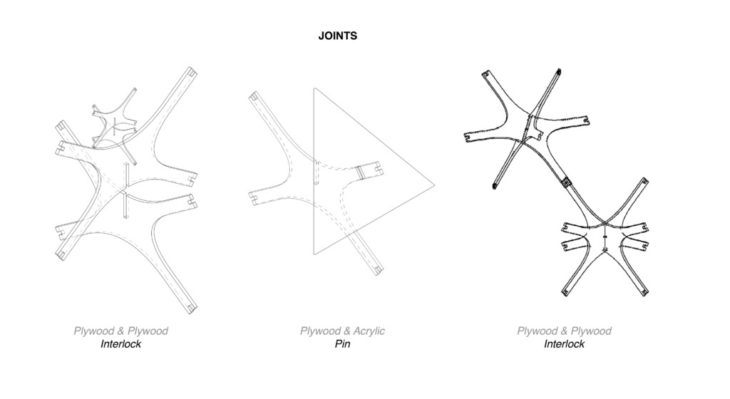

DISJOINTED UNITY

Disjointed Unity is an experiment in Laser Cutting Fabrication seeking to develop a recursive geometry with a prominent supporting structure. Utilizing a plywood sub-structure and acrylic shell, the recursive structure within steps to the forefront.

Diamond Form and Structure Generation

STRATEGY

Materials: Plywood – 4mm // Clear Acrylic – 3mm

Machine: Epilog 75

PLYWOOD –

Speed / 20

Power / 95

Frequency / 300

ACRYLIC –

Speed / 15

Power / 90

Frequency / 5000

FINAL

Aggregation

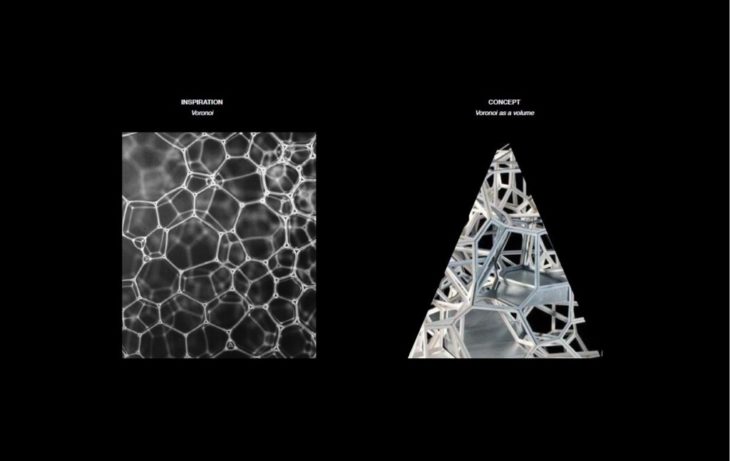

SPIDER WEB

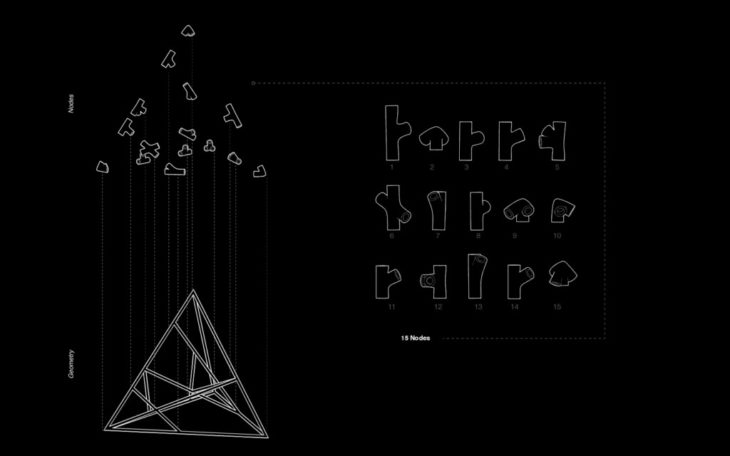

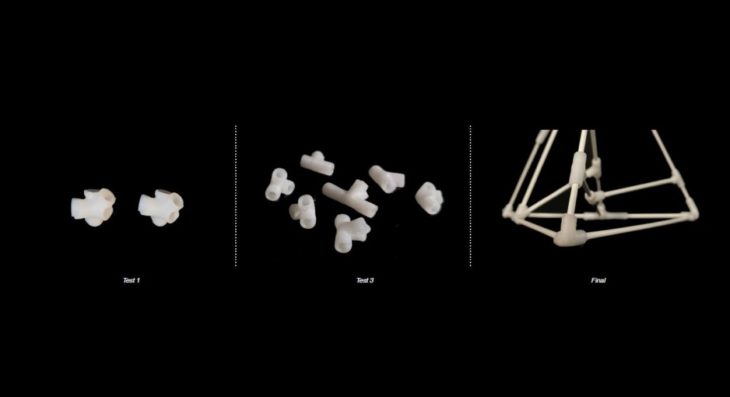

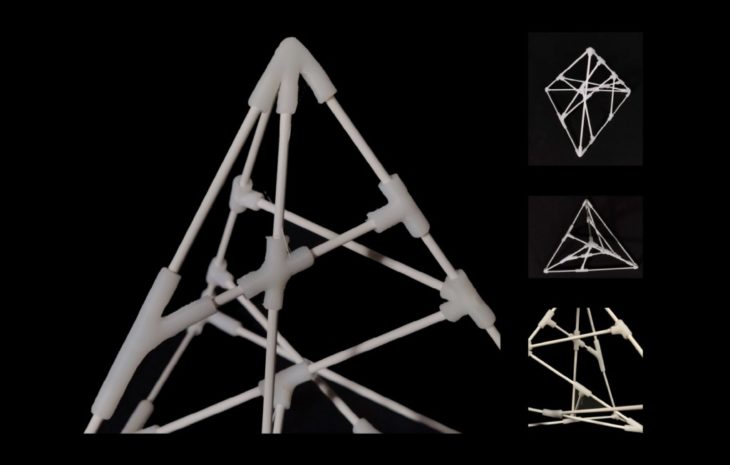

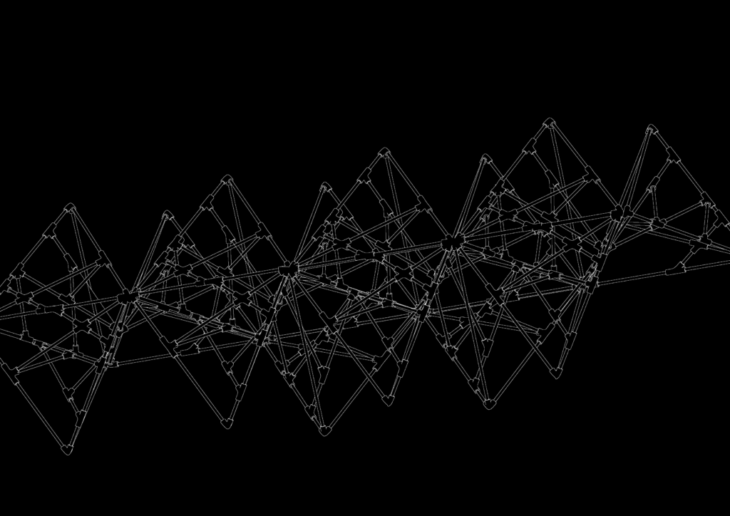

Spider Web is an experiment in 3D Print Fabrication. This exercise dove into the construction of a recursive geometry using 3D Printed nodes and 2mm carbon fiber rods. In this project a test of varying nodes was conducted. How many different nodes could be compiled into a singular geometrical form?

Taking inspiration from three-dimensional voronoi patterns it became possible to create unique connections throughout the volume.

STRATEGY

Total number of nodes: 15

Internal node diameter (modelled): 2.4 mm

Node wall thickness (modelled): 1.2 mm

Total print time: 89 mins

Material type: Z-ABS 2

Machine specifications: Zortrax M200 (M200 Plus)

Layer thickness: 0.14mm

Support type, angles and specifications: Automatic – 20°

Node Assembly

Node Tests

Final Assembly

Aggregation