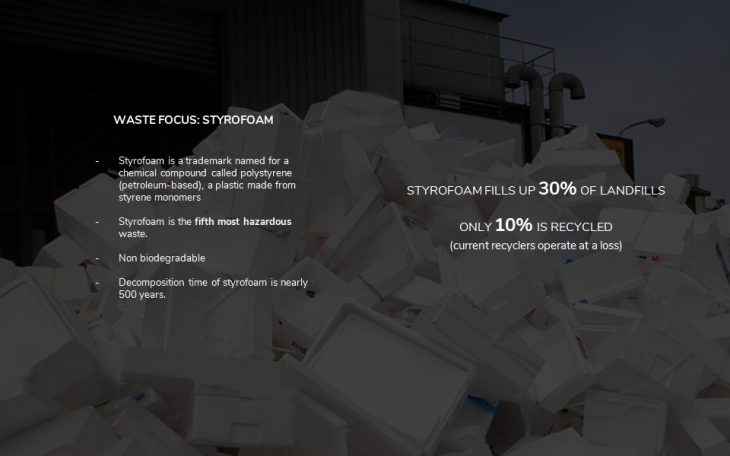

Our environment, globally, is in a current state of distress. Our oceans continue to accumulate improperly discarded waste. The most visible waste it has inherited is plastic waste which comes in various forms. Among the plastic family is Styrofoam, a material that is in a constant state of production.

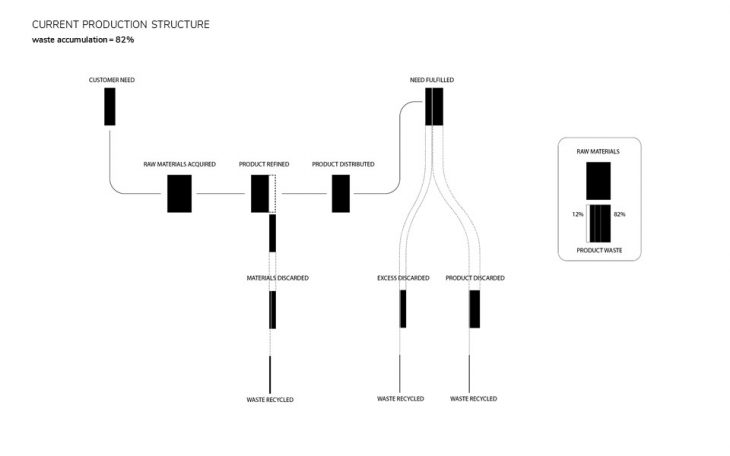

Because of the current structure of our customer-product relationship, manufacturers are producing excess amounts of materials. The diagram below illustrates the current structure.

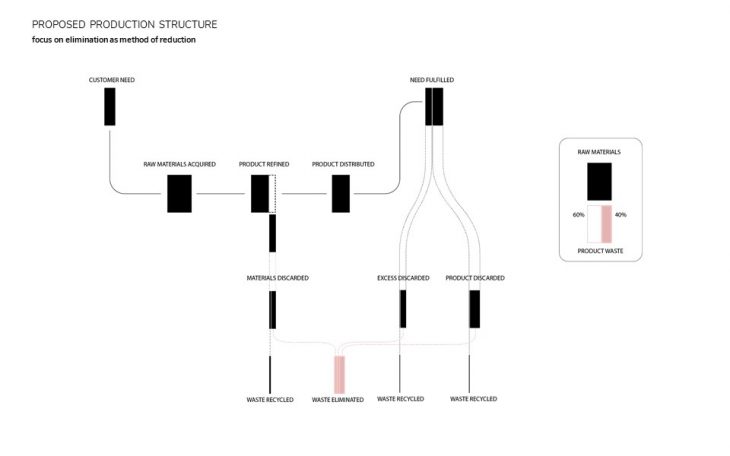

This project’s goal aims, not only to recycle Styrofoam, polystyrene, waste, but to eliminate it as well by converting it into organic matter using mealworms. The diagram below shows where the project aims to position itself.

A current study shows that mealworms can safely consume Styrofoam and convert it into organic waste matter.

Tests

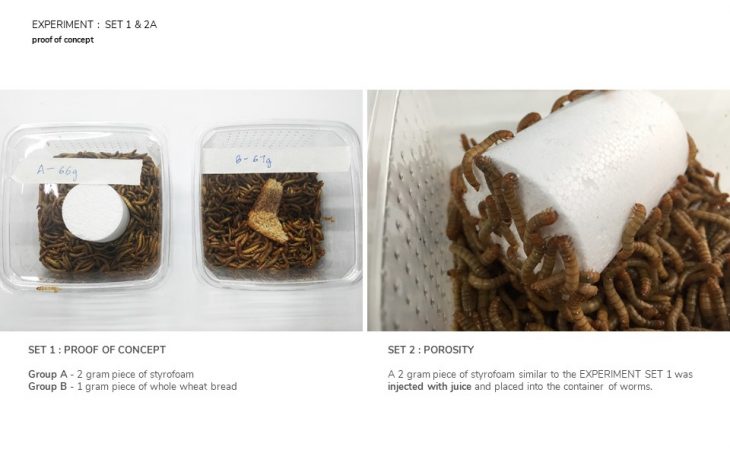

The types of worms were acquired to start testing the viability of this proposal, the mealworm and the superworm, both are the same species of worms. The first set of tests done was to prove the concept.

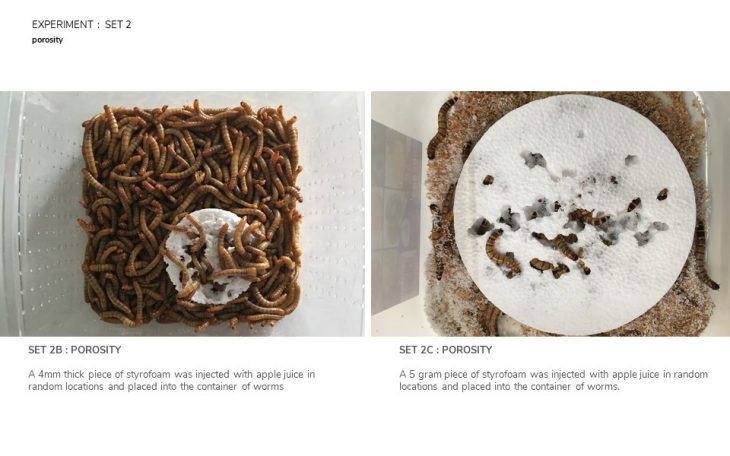

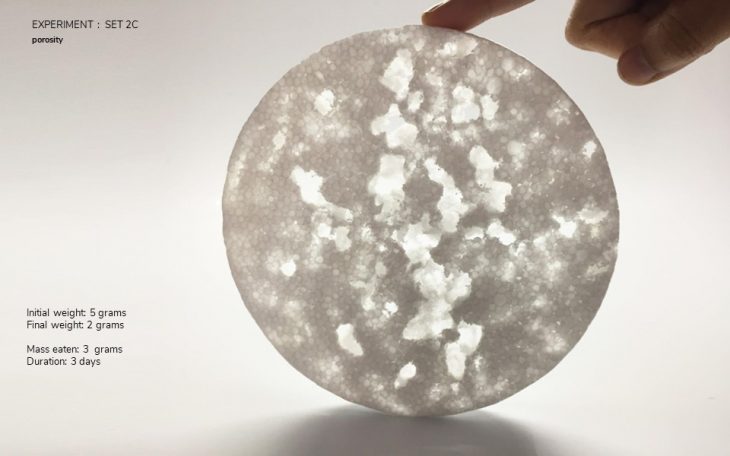

In order for the worms to penetrate the Styrofoam, a syringe was used to inject juice into the Styrofoam. The worms then had an incentive to dig deeper in the Styrofoam.

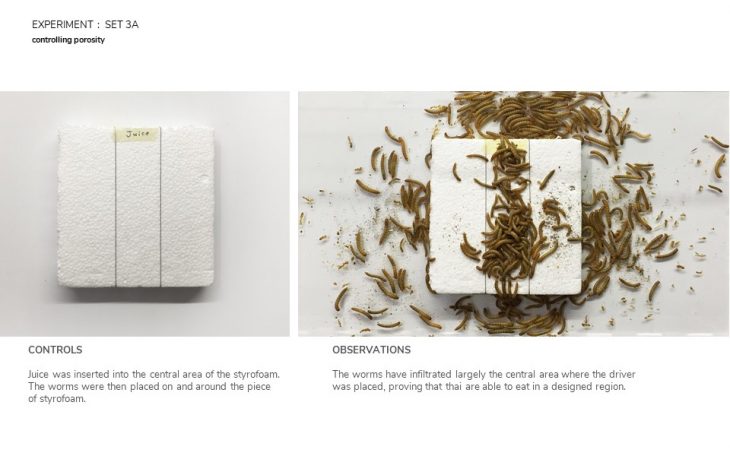

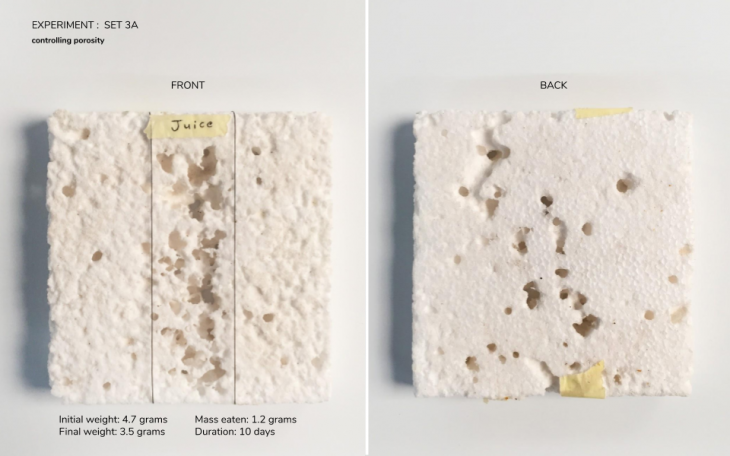

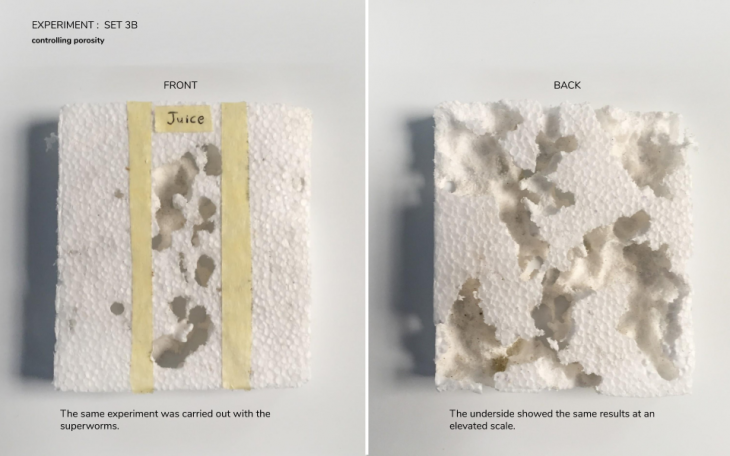

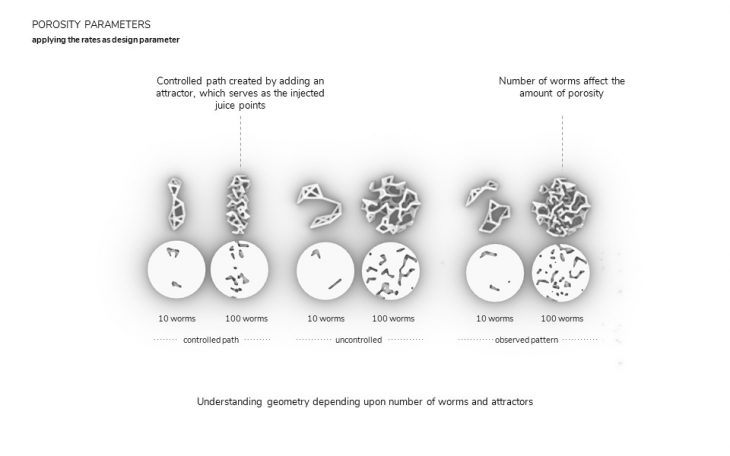

The next set of tests were carried out to test the control of the worm’s eating pattern using juice in specific regions.

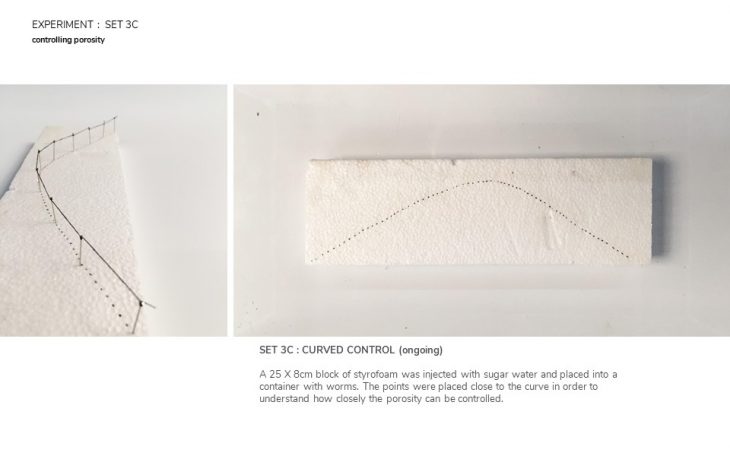

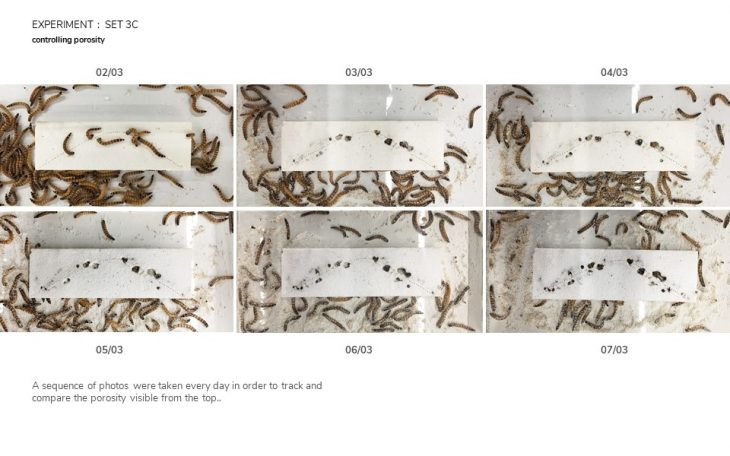

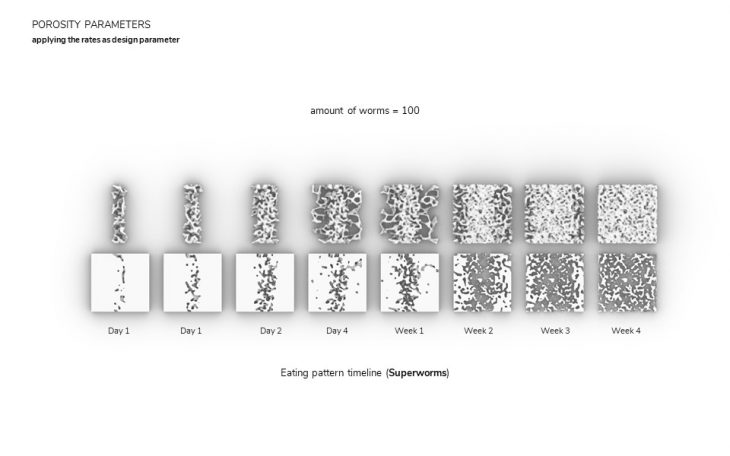

Upon proving that the eating pattern of the worms could be controlled, several tests were carried out to see how much control could be gained. The following images were taken daily in order to track eating patterns.

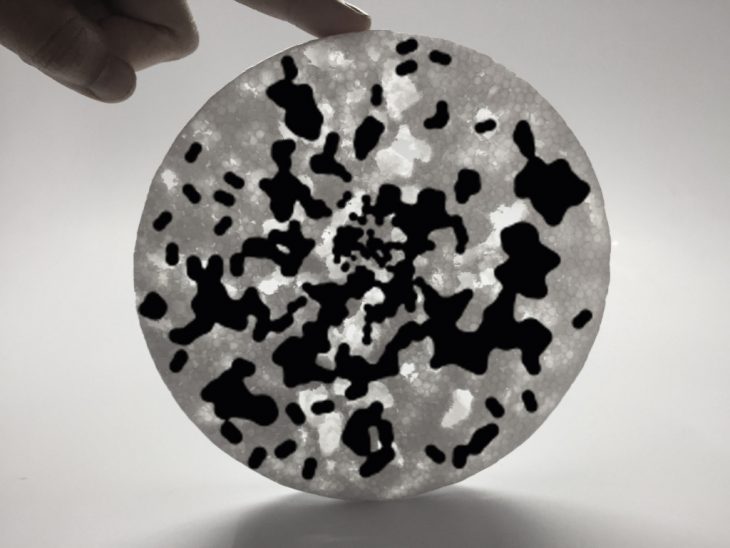

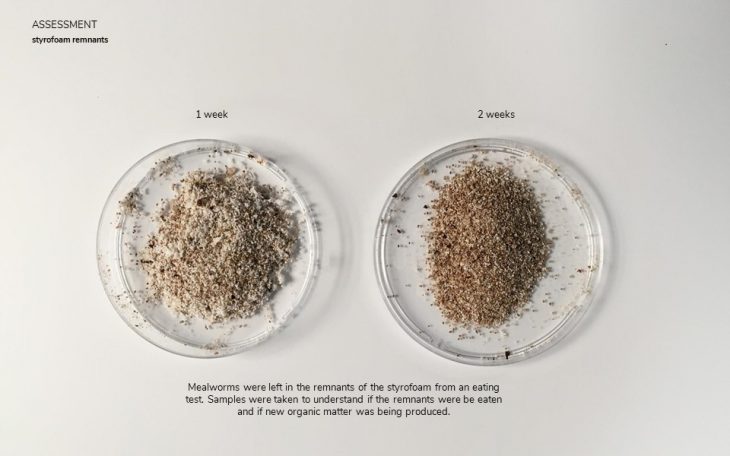

After several sets of tests, multiple groups of worms were left in the Styrofoam remnants after a bit of messy eating. This was done in order to track the composition of the remnants. In theory, the remnants would turn brown and obtain a new consistency if it was being converted into organic matter. The image below proves the theory.

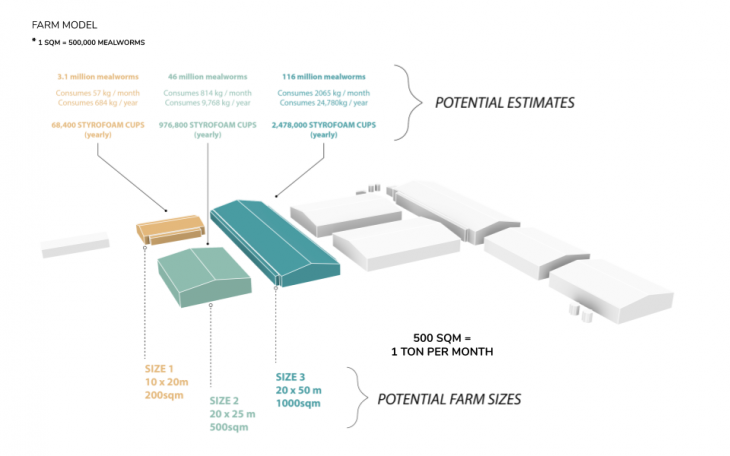

With the recorded data from all the experiments, 6 well controlled sets were used to calculate the average eating rate for both the mealworm and the superworm. The following estimates were made based on the rates.

Mealworm farm for the elimination of polystyrene waste model

With the data gathered, a sustainable business model for the elimination of PS waste could be developed. The model aims to develop a mealworm farm on the campus of the waste facility in order to obtain PS waste without creating the need for transportation. The mealworms are also reproduced on the farm in order to naturally cycle the worms rather than obtain more worms. The waste is then converted to organic matter and excess worms are sold as feed to sustain the operation.

The mealworms are also reproduced on the farm in order to naturally cycle the worms rather than obtain more worms. The waste is then converted to organic matter and excess worms are sold as feed to sustain the operation.

The chosen model for the farm is a 500sqm unit that is able to eliminate 1 ton of PS per month, 12 tons per year. Greenery is planted within the facility in order to absorb the natural production of non-methane gases produced by the mealworms.

Eating pattern exploration and installation proposal

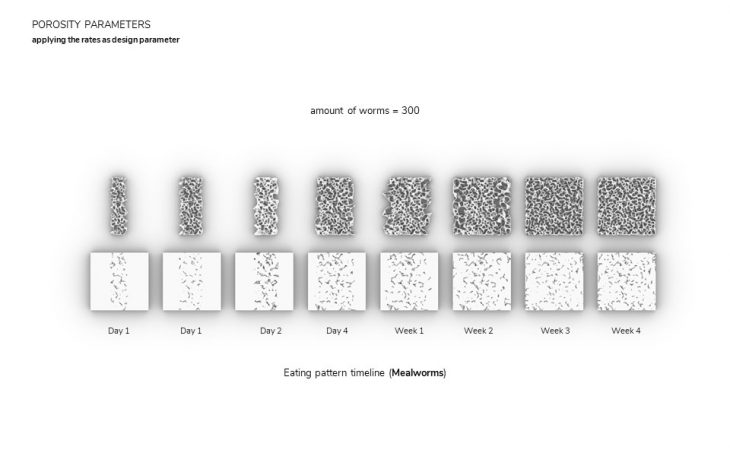

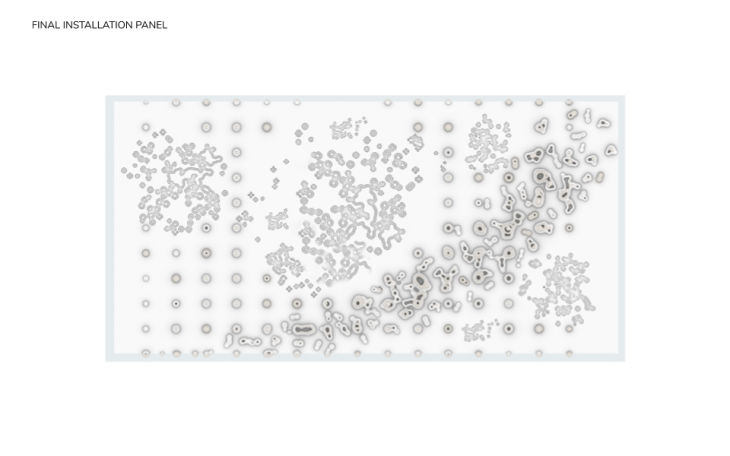

With the data and gathered understanding of the eating patterns, parameters were extracted to simulate the eating process and porosity creating of the worms. A curve was used to indicate the placement of the juice, points populating a geometry accounted for the amount of worms which were then pulled towards the curve. The strength of the porosity was used to simulate the factor of time. With these parameters porosity was able to be simulated.

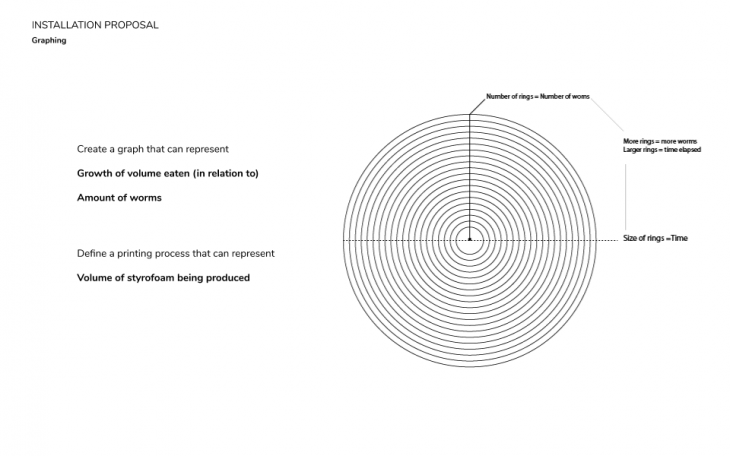

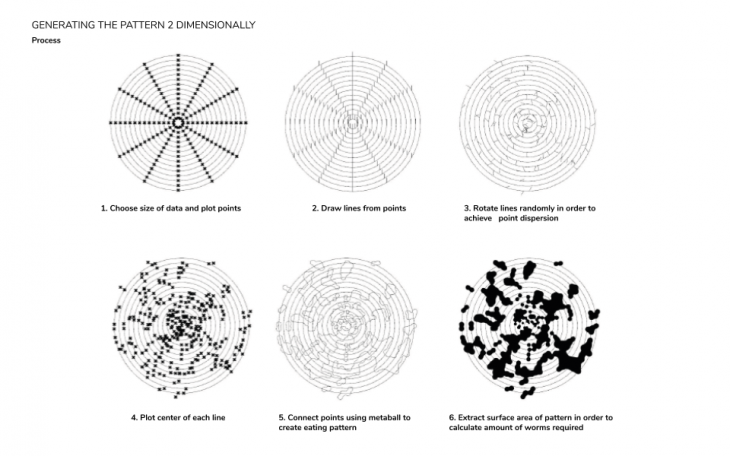

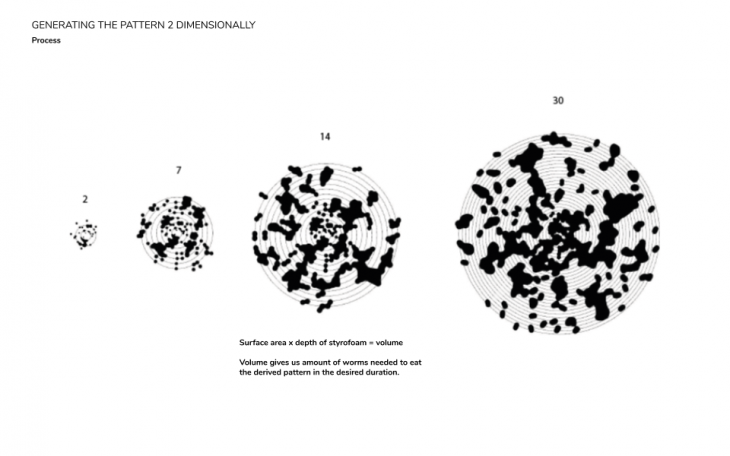

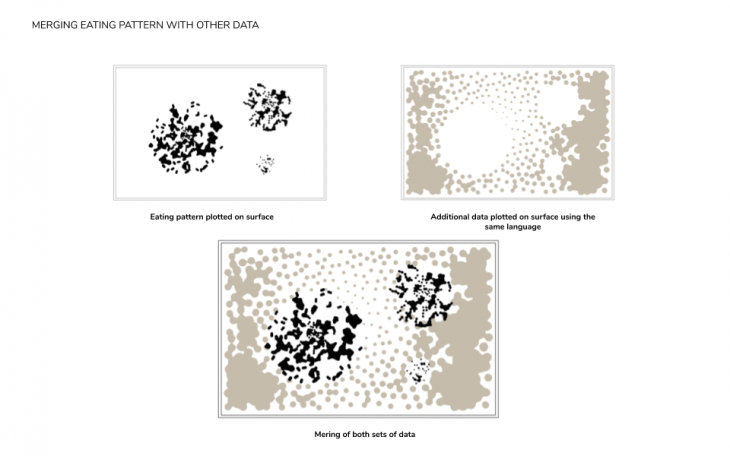

By understanding how to replicate the eating patterns in three dimensions, developing a way to map the pattern in two dimensions was mostly laid out. By having a flat map of the eating pattern, new possibilities of creating graphic representations and overlapping the pattern with historic data could be easily constructed. This exploration was aimed towards developing an installation that could educate the audience with readable data.

Once several eating rate representations are chosen, they can then be plotted onto a surface. This installations proposes layering another set of data with the eating rate. Below is the concept of the merge.

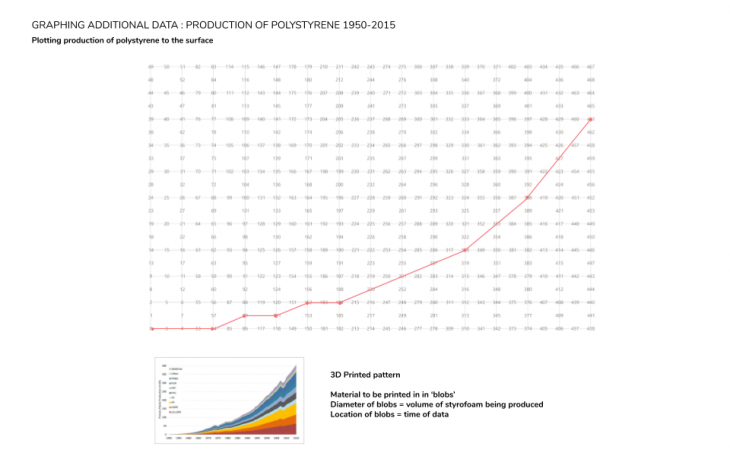

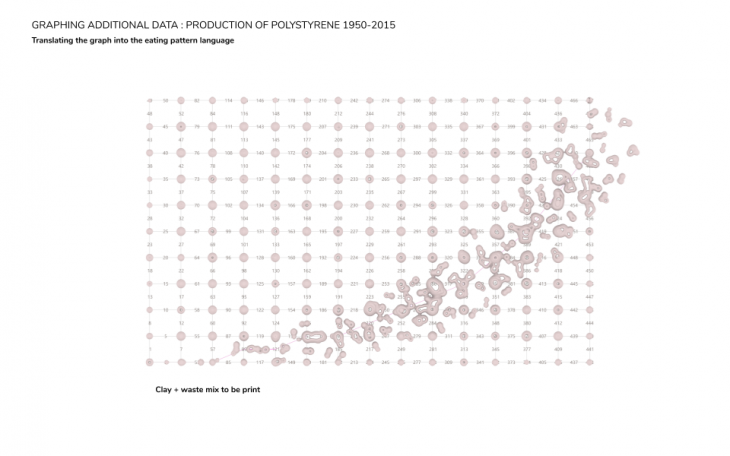

The second set of data chosen was the production of polystyrene from 1950-2015. This creates an interesting relationship between the eating rate pattern because it represents addition while the eating rate pattern represents subtraction.

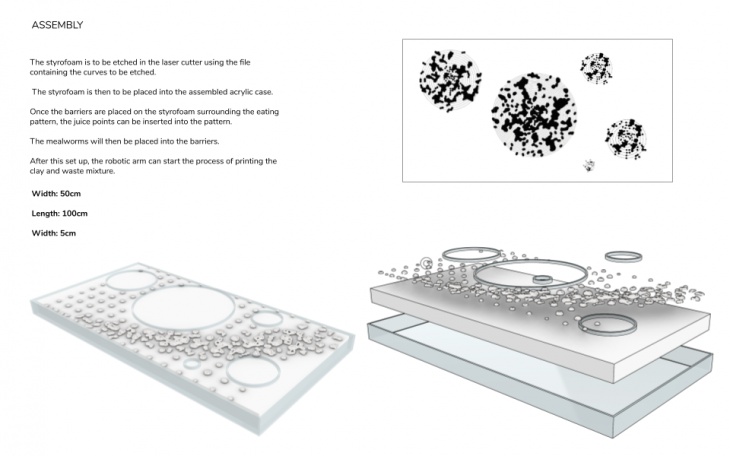

The PS production graph would be 3D printed, additive inorganic manufacturing, using white clay mixed with the organic matter produced by the mealworms. The mealworms would then eat the plotted eating rate pattern, subtractive organic manufacturing, creating an interesting relationship between the two geometries.

The final installation prototype is a simple block that is easily composed using available fabrication resources.

The efforts of this project have, so far, educated the audience it has entertained and have led to interesting discussions and ideas bringing all parties involved closer to changing the impact of plastic in the environment. By promoting these processes of nature, these efforts aim to change the narrative of pollution that is currently stifling other natural processes in hopes of creating a new narrative, one where human needs and agendas can pave a way for these natural processes rather than stand in the way of them.

Students: Eve Nnaji, Madhavi Ojha

Faculty: Chiara Farinea, Mohamad Elatab, Raquel Villodres

Teaching Assistant : Fiona Clara Louise Demeurs