Relaxed Mesh Optimization.

Rationalization of complex geometry is a key process in order to execute its manufacturing and assembly. Specifically, meshes can be operated by constructing and decomposing their graphs using the faces nodes as connecting points.

Through this rationalization, process stripes can be generated with different organizational logics. For example, the shortest path between two faces or, after defining weights to graphs stripes can be generated through a K-Means clustering.

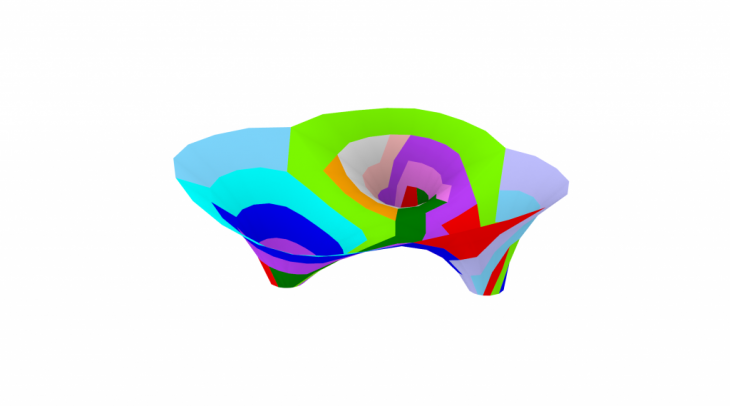

This project explores two rationalization approximations of a relaxed mesh, the first is by K-Means clustering using the node’s height and horizontal orientation, and edges angle. The second is the shortest path between two centroids.

The second alternative was chosen to fabricate the mesh, because of the tension of the strips once they were assembled, generation an interlocking of the folds generated tension and structure.

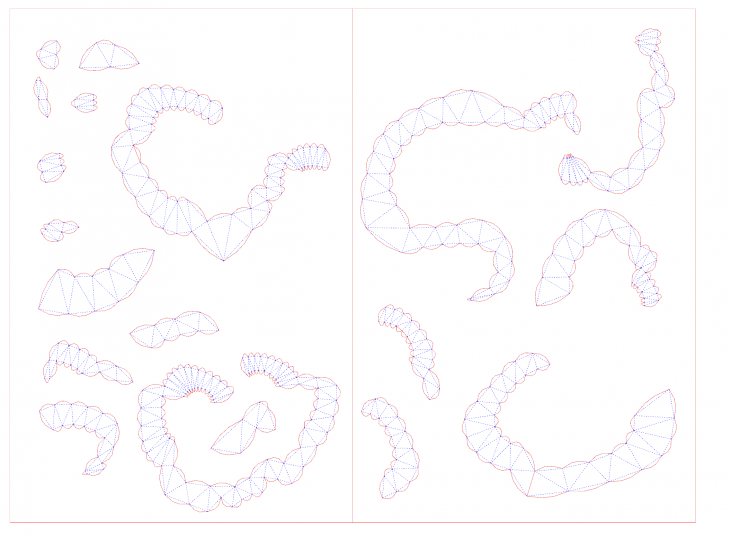

Final Mesh Stripes (18)

Laser cutter file

Process Video