Research scope

Carbon dioxide emissions from cement production in concrete manufacturing

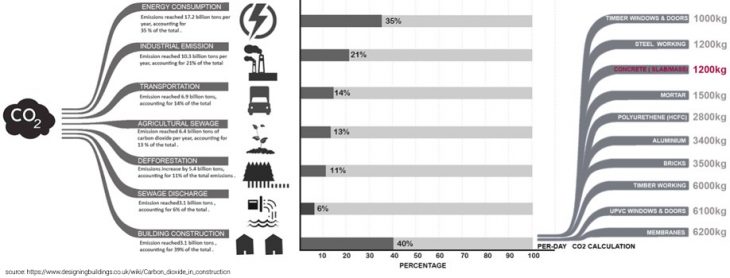

Construction sector is actively responsible for the largest production of carbon dioxide emissions out of all other industrial sectors, its share being 40 percent of the total amount. Among most common building materials concrete accounts for 1200 kg of total emissions being produced per average day of contruction.

Concrete is one of the most widely used materials for construction and there are legitimate reasons that contribute to its popularity, some of being:

- strength in compression

- durability (gains structural strength over time)

- customization

- fire and corrosion resistance

- ease of maintenance

- lower operational costs, etc.

However, no matter how many advantages concrete has to offer in construction, there are obvious downsides to its use that are derived from its manufacturing process.

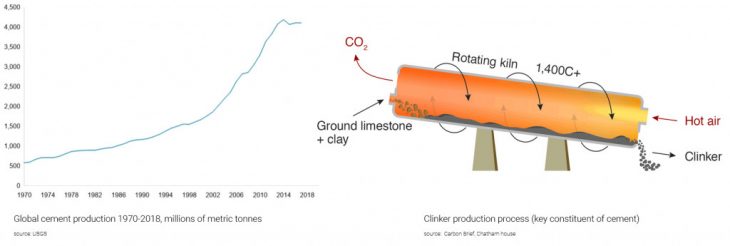

Concrete’s key ingredient, ordinary portland cement (OPC), accounts for between 6% and 10% of all global carbon dioxide emissions, contributing substantially to climate change. Most of those emissions are produced during clinker manufacturing stage

Cement manufacture contributes greenhouse gases both directly through the production of carbon dioxide when calcium calbonate is thermally decomposed, producing lime and carbon dioxide (65%) and also through the use of energy, particularly from the combustion of fossil fuels (35%)

Cement manufacture contributes greenhouse gases both directly through the production of carbon dioxide when calcium calbonate is thermally decomposed, producing lime and carbon dioxide (65%) and also through the use of energy, particularly from the combustion of fossil fuels (35%)

The CO2 emission from the concrete production is directly proportional to the cement content used in the concrete mix; 900 kg of CO2 are emitted for the fabrication of every ton of cement, accounting for 88% of the emissions associated with the average concrete mix.

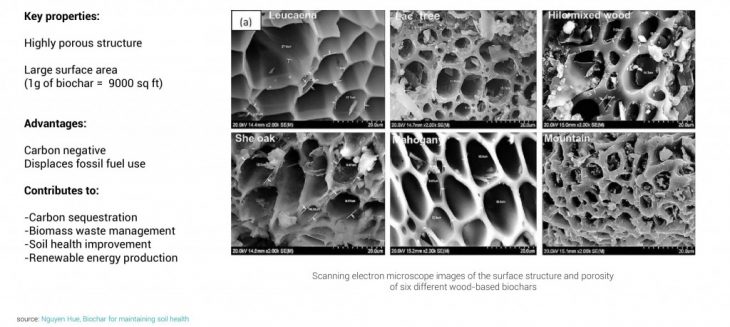

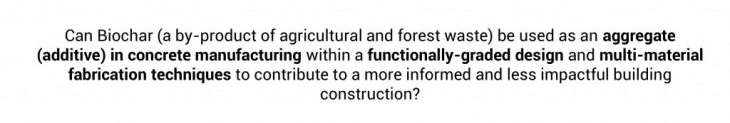

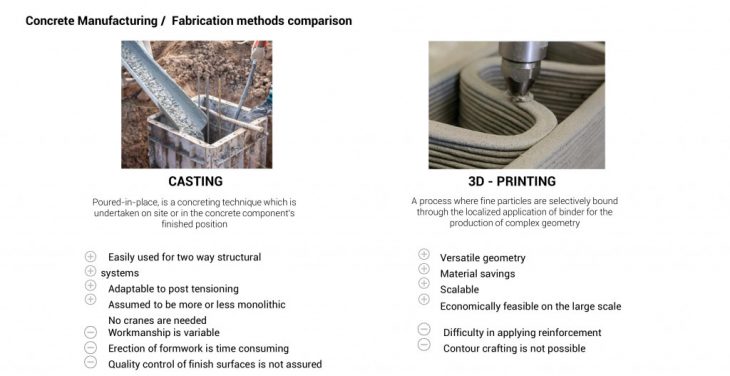

The principal strategy for reducing the amount of embodied emissions explored in this project is an effective reduction of cement content applied in concrete manufacturing by the introduction of carbon negative materials to concrete composition to create novel composites.

Biochar introduction

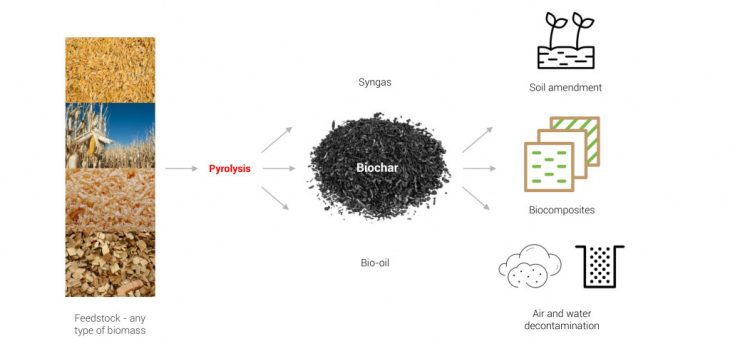

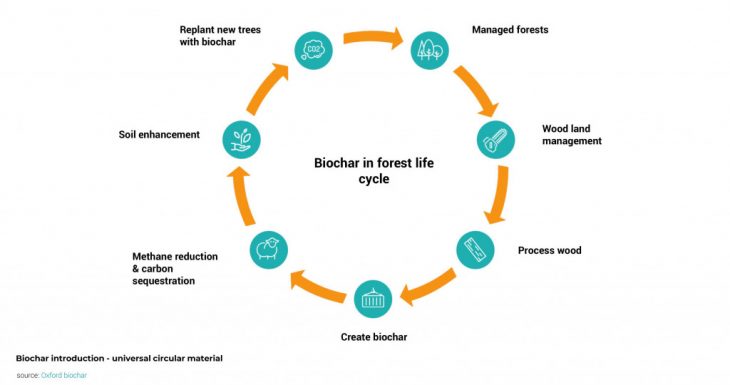

When biomass is undergoing through a pyrolysis process (heating feedstock in an oxygen deprived environment) three subsequent by-products of different physical state are generated: syngas, or synthesis gas, liquid matter – bio oil and solid resedue, which is known as “biochar”.

When biomass is undergoing through a pyrolysis process (heating feedstock in an oxygen deprived environment) three subsequent by-products of different physical state are generated: syngas, or synthesis gas, liquid matter – bio oil and solid resedue, which is known as “biochar”.

Currently biochar’s most popular application is acting as a soil amendment for both carbon sequestration and soil health benefits. However, during the last decade, reseachers have been investigating the potential of using biochar for non-soil applications, such as: insulation, air and water decontamination, humidity regulation, protection against electromagnetic radiation, and, of course, construction.

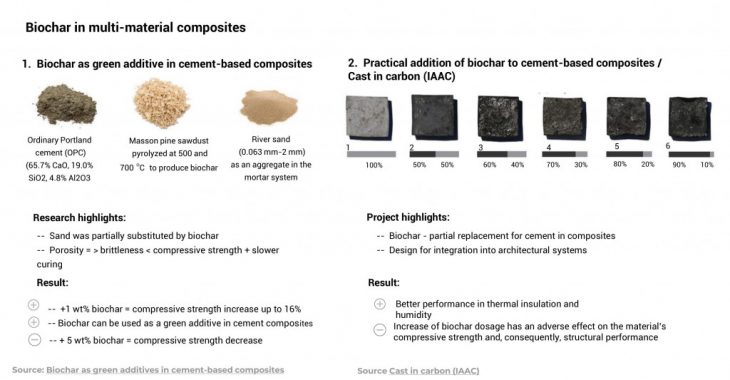

Research question

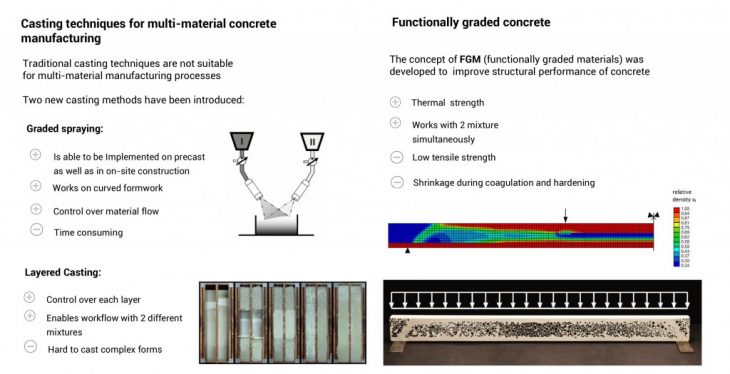

State of the art

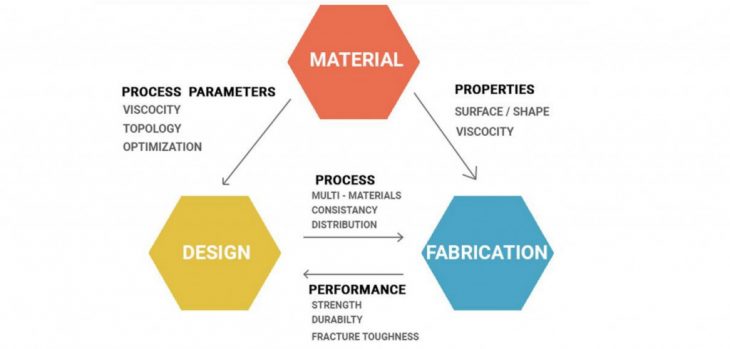

Project Framework

Project Outline

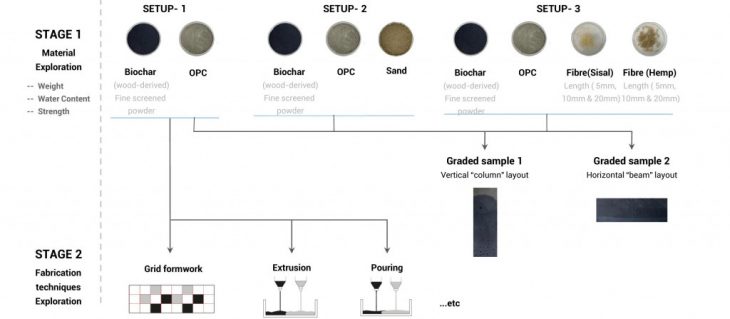

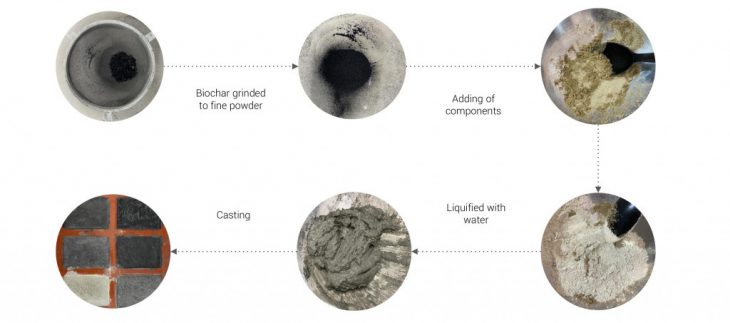

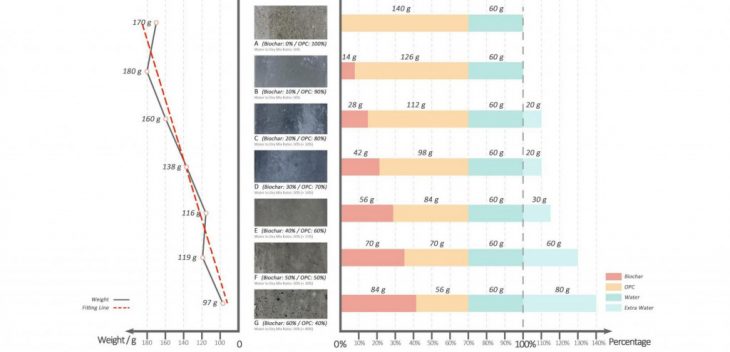

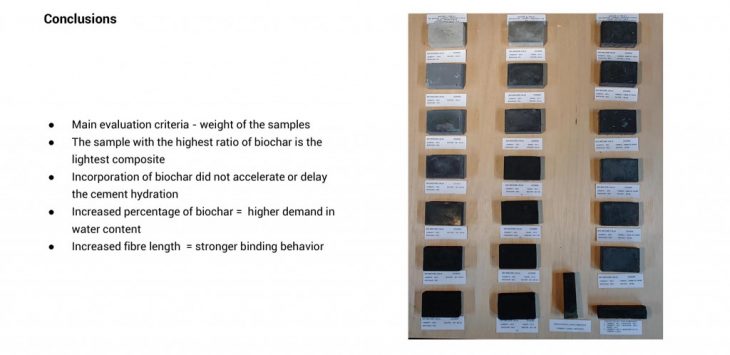

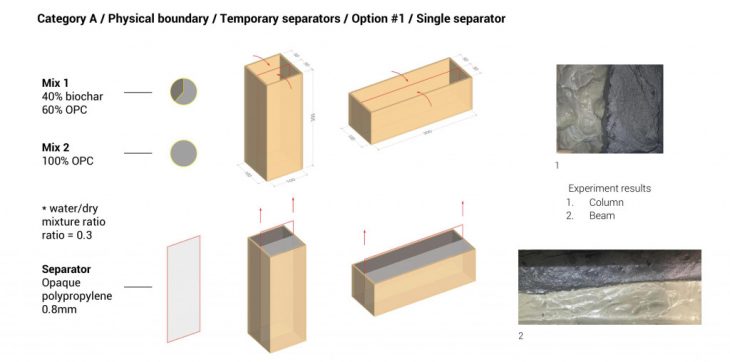

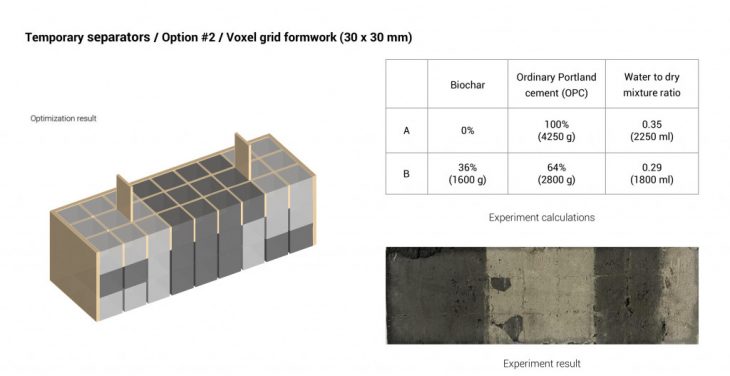

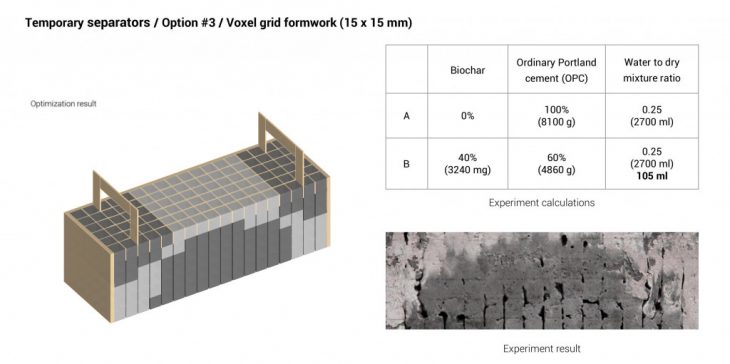

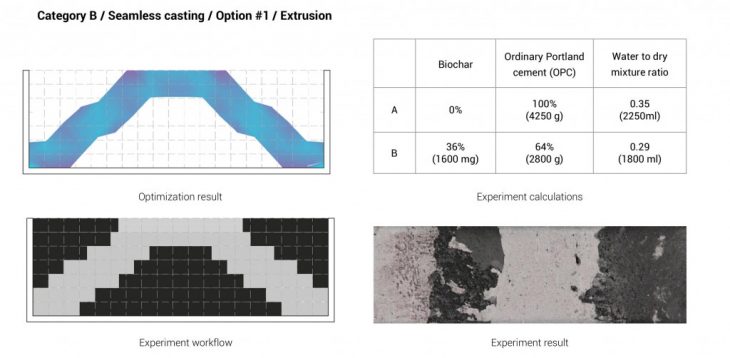

First step of the prototyping was dedicated to understanding the principal behavior and properties of the composite

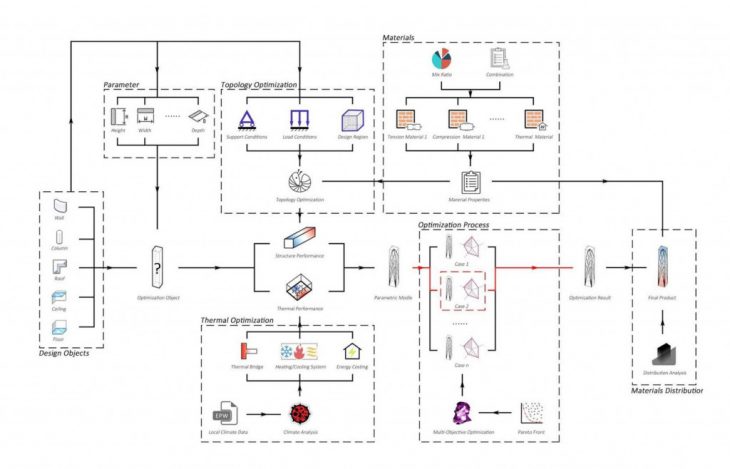

General workflow

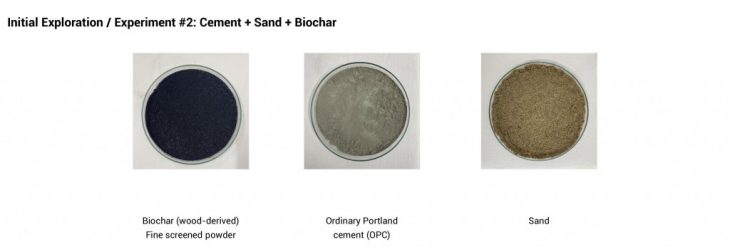

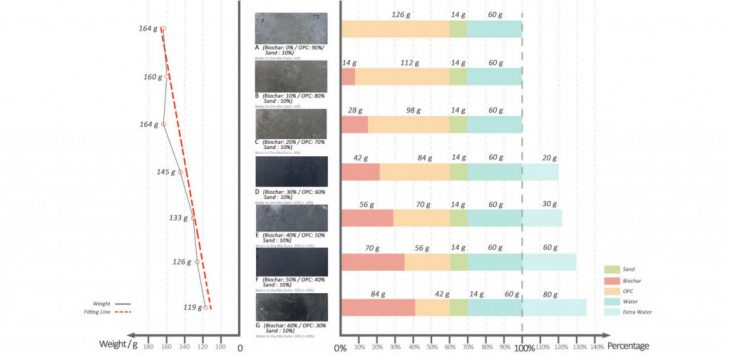

Experiment #2 consisted of biochar, cement and sand. The content of the sand was kept at 10%. Cement content was being gradually reduced again by 10% at a time

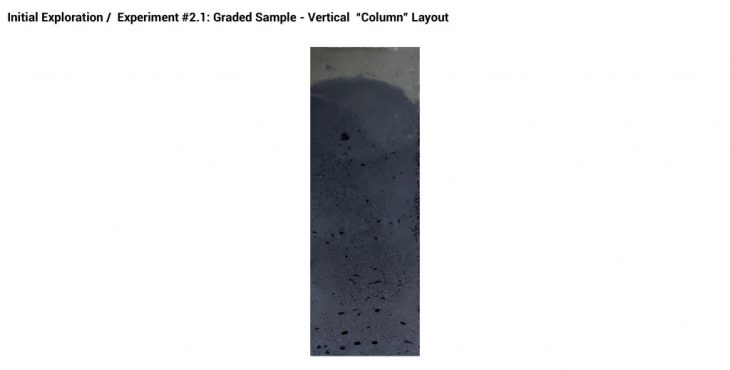

In order to investigate the binding behavior of the different mixtures a graded layered sample was produced (based on experiment #2)

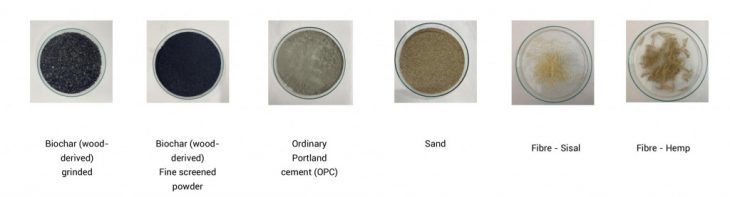

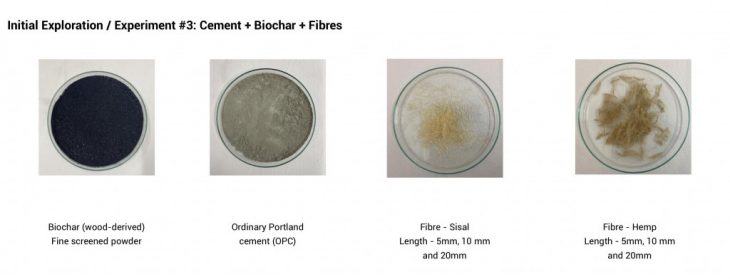

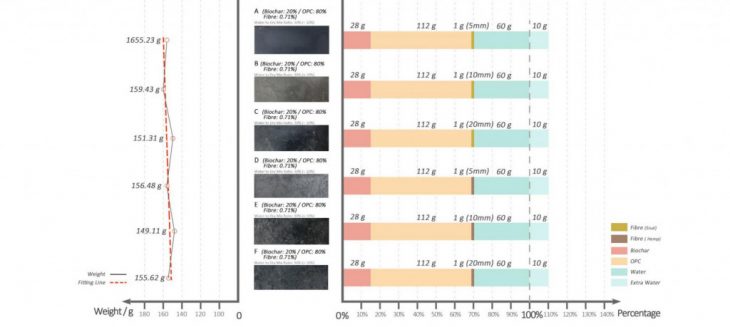

For experiment #3 hemp and sisal fibers in the lengths of 5, 10 and 20 mm were added to the composite in order to enhance the sample’s structural performance under tension forces

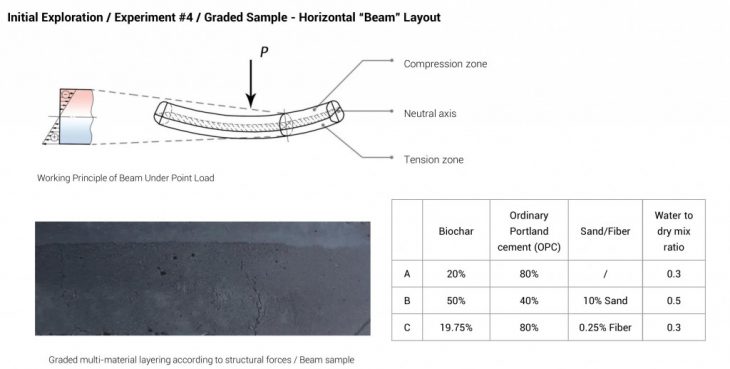

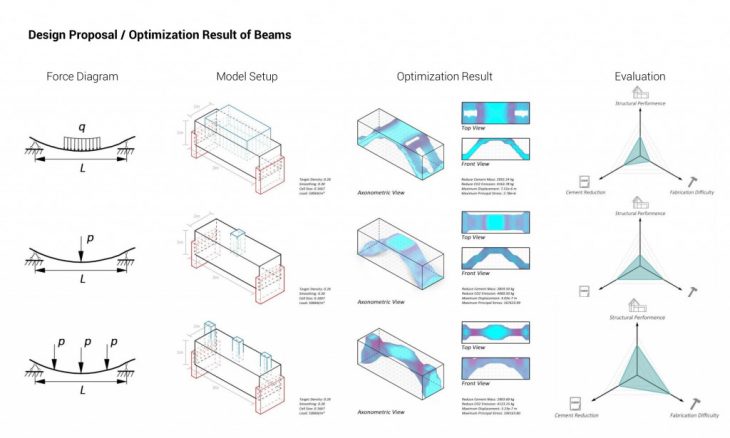

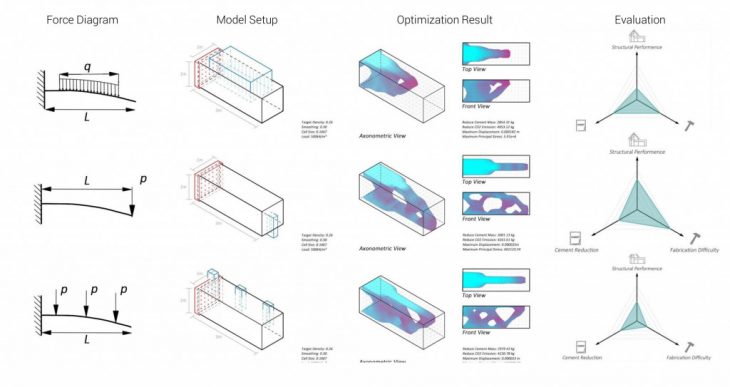

With the understanding of fiber properties, a horizontally oriented element based on the working principle of a beam under point load was produced.

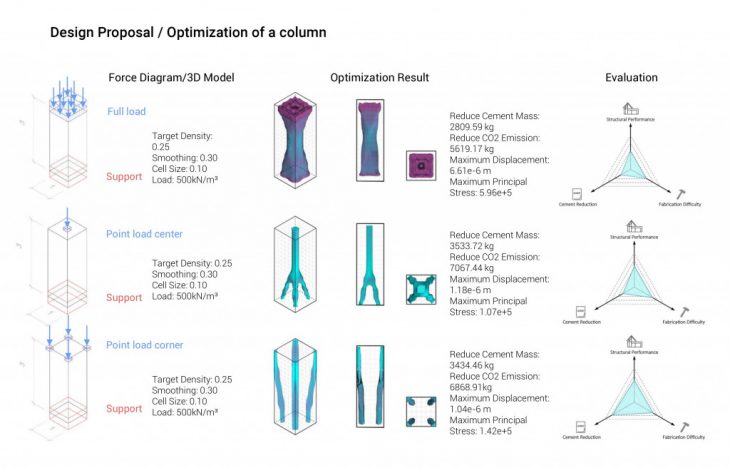

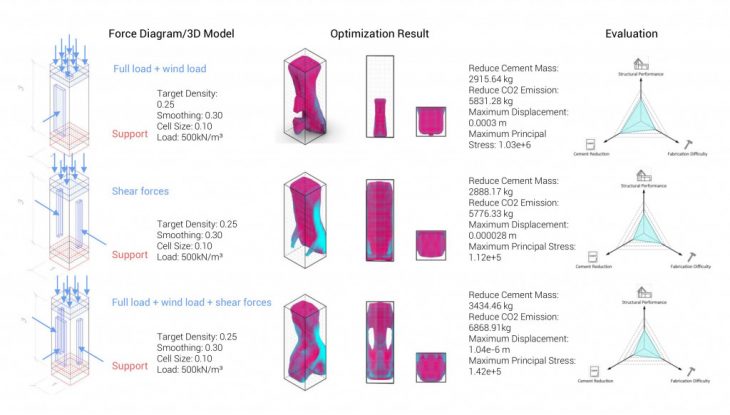

Design Proposal

Current design proposal is to present a whole building element manufacturing process that is based on data acquired from conducted experiments and algorithmic systems. Furthermore, structural analysis and thermal performance analysis will be applied in order to optimize building elements.

Experiment documentation / Timelapse

Multi-material allocation fabrication strategies of biochar-cement composites towards functionally-graded structural elements is a project of IAAC, Institute for Advanced Architecture of Catalonia developed in the Master in Advanced Architecture 2020/21 by Students: Elizaveta Veretilnaya, Liang Mayuqi, Stefanie Eleonore Thaller & Lekha Gajbhiye and Faculty: Areti Markopoulou, David Andres Leon & Raimund Krenmuller. Faculty Assistant: Nikol Kirova