MULTITASK END EFFECTOR PU FOAM EXTRUDER+CNC

The Multitask end effector is a project developed during the Hardware I Seminar of the MRAC-20/21-program. The objective of the seminar was to give an overview of the state of the art in robotic actuation, discuss the practical implementation of such actuators, and brainstorm how these actuators and the robotic arms could bring new levels of versatility, agility, and efficiency to the production and construction processes.

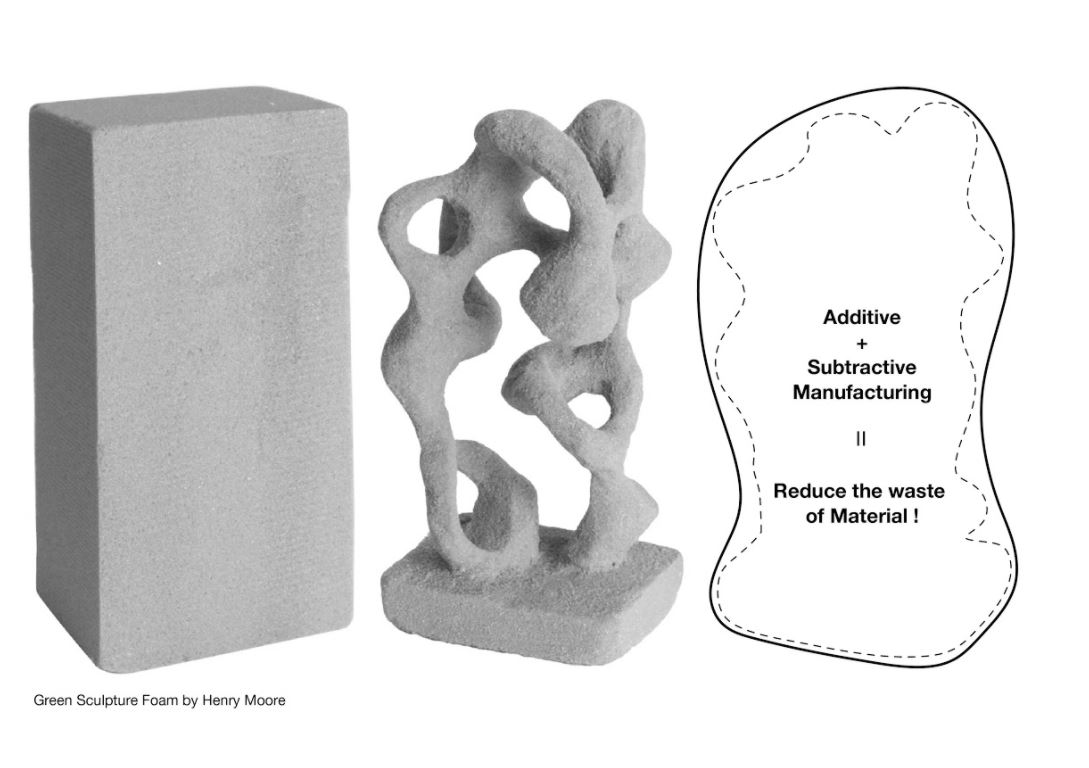

CONCEPT

The initial idea was to develop an end effector which can be multitasking. Finally, we decided to use PU foam for additive manufacturing and CNC milling spindle as subtractive manufacturing.

TECHNIQUE

COMPONENTS

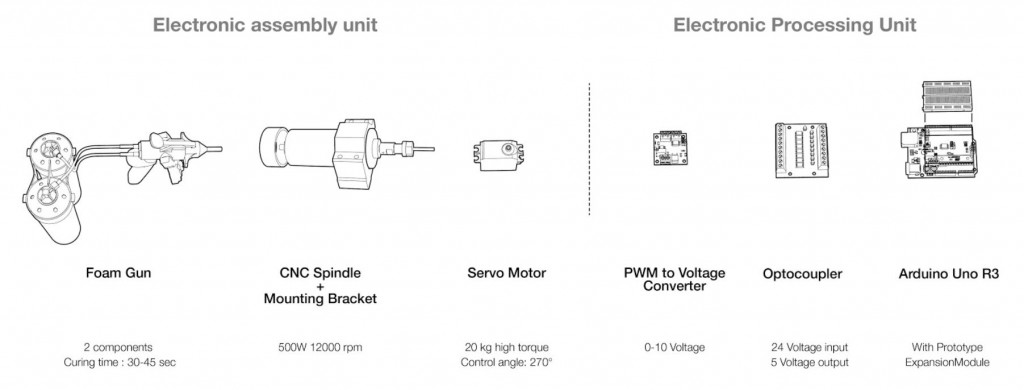

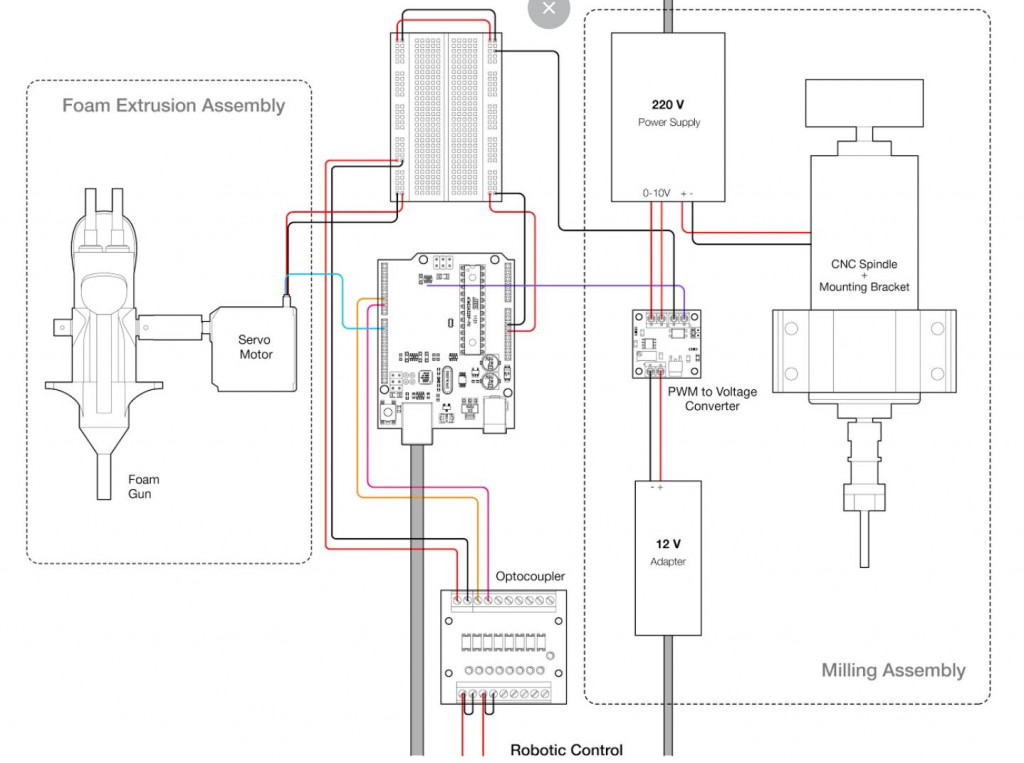

The complete assembly can be divided into 2 parts;

- Electronic assembly unit

- 2 Electronic processing unit – This part is responsible for processing the commands (input) and provides commands to the output devices(1st part)

TECHNICAL DETAILS

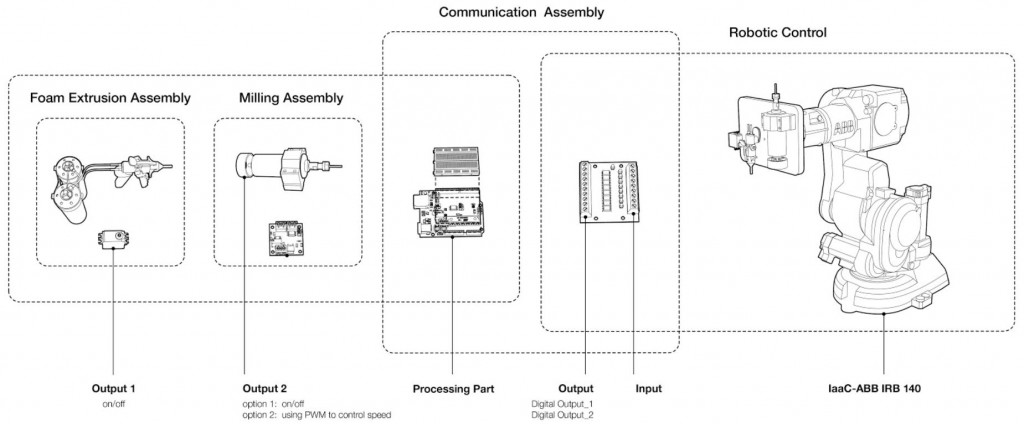

The whole assembly has 2 technical divisions;

- Output devise – PU Foam extruder and CNC milling spindle

- Communication assembly

- Robotic control (robotic arm)

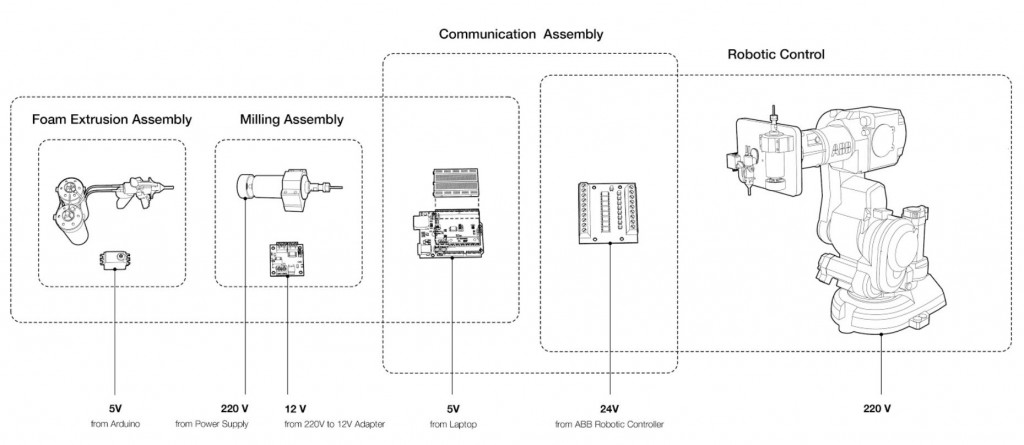

POWER REQUIREMENTS

- PU extruder is driven by servo motor (20 kg/cm) which has been provided 5v power supply.

- CNC spindle has been provided a 220v power supply.

- Communication devices – Arduino has been provided a power supply of 5v

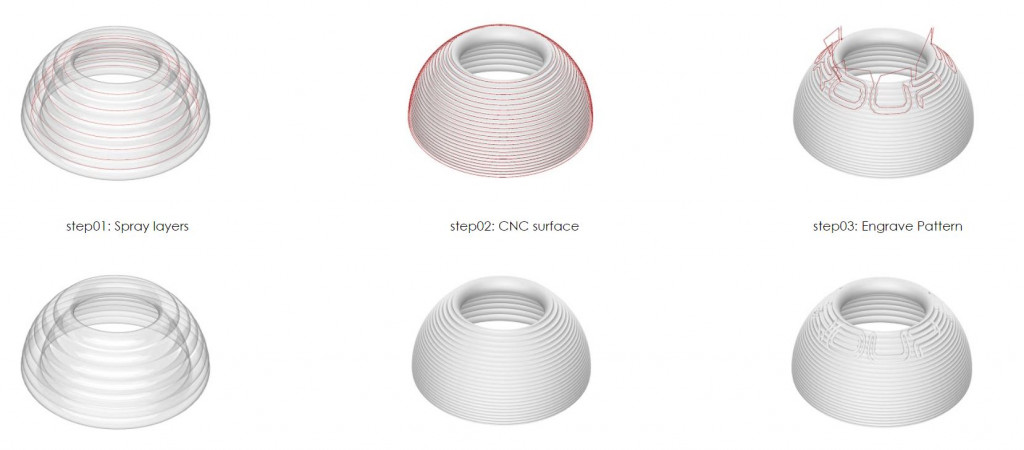

PRINTING AND MILLING FIRST PROPOSAL

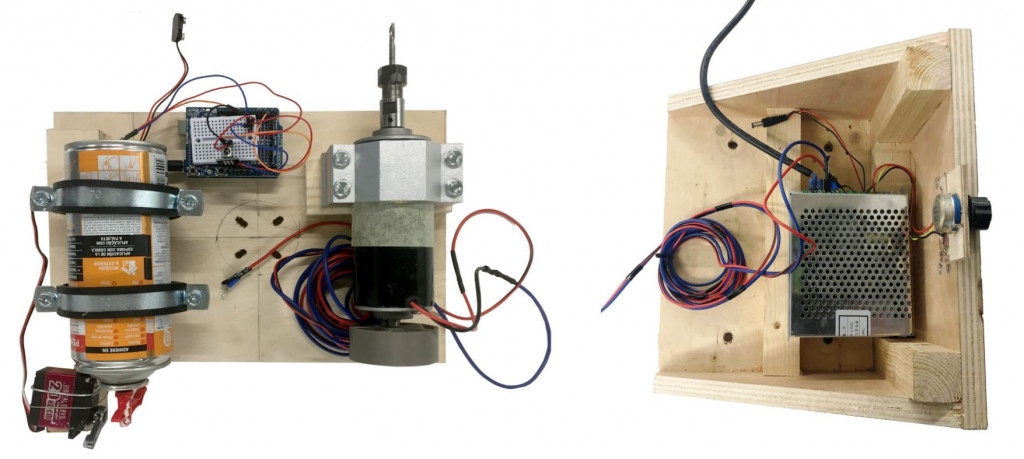

FIRST PROTOTYPE

The first prototype was built using a normal polyurethane foam CAN and CNC milling spindle. CAN has direct actuation using a servo motor. Both, CNC spindle and Foam extrusion servo are connected to Arduino and Arduino to robotic arm optocoupler.

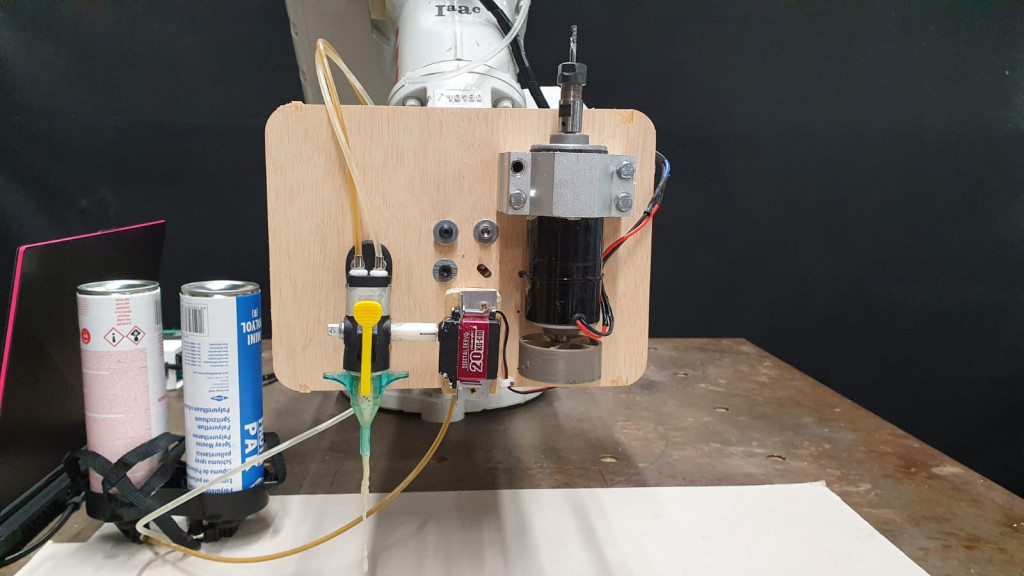

LATEST PROTOTYPE

In the latest prototype PU FOAM CAN was replaced by a 2 component PU FOAM which is quick-drying and also has a CNC milling spindle on the other face of the end effector plate. Both, CNC spindle and Foam extrusion servo are connected to Arduino and Arduino to robotic arm optocoupler.

SIMULATION

Below simulation was generated using the grasshopper and ROBOT plugin(grasshopper) to see the end effector functioning before the live test on the robotic arm.

FINAL PROTOTYPE

This video is the final collective output of the concept, technical details, few live tests. The project is still a work in progress and hopefully, advanced upgrades will be posted in near future.

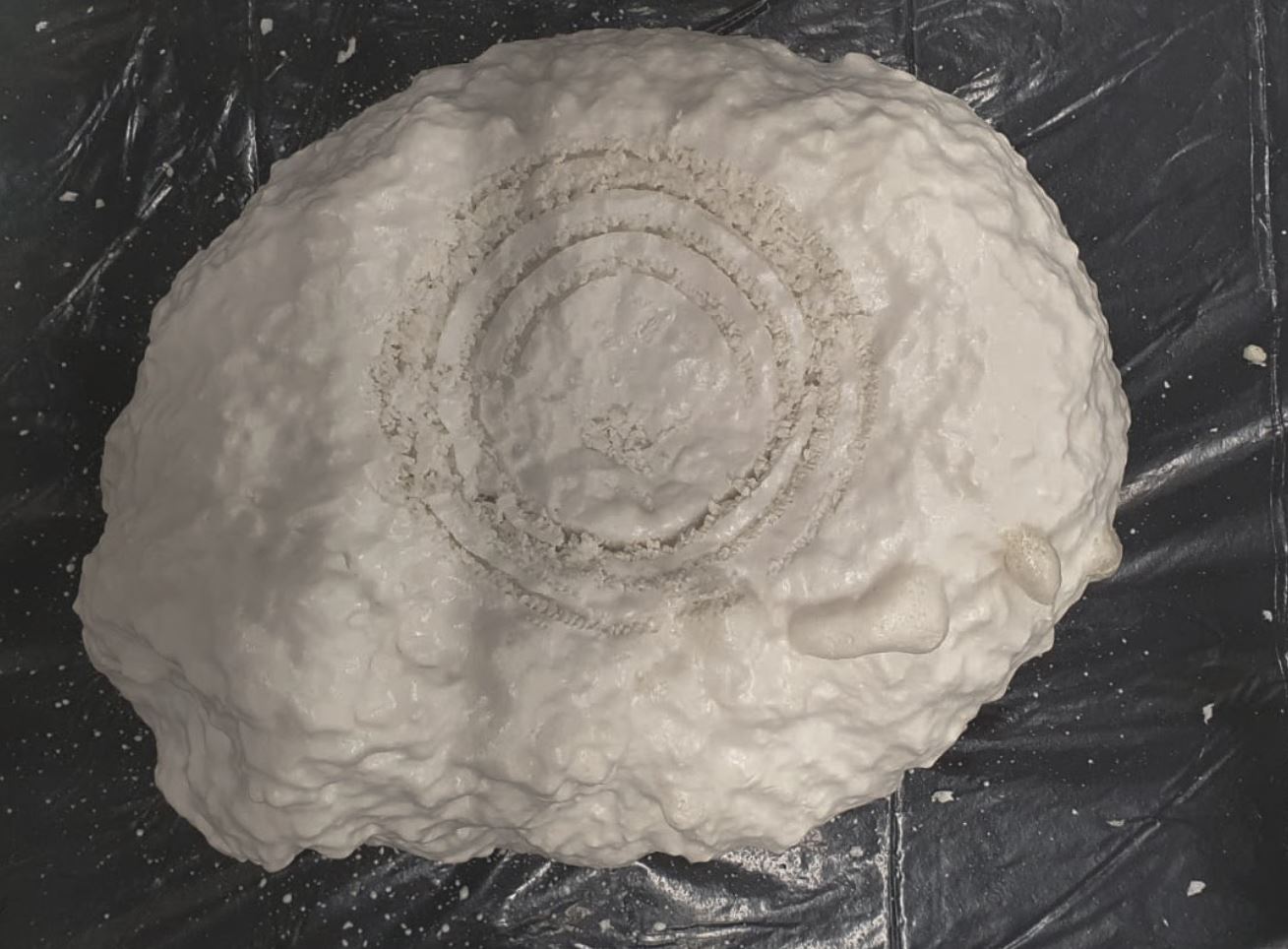

FINAL OUTPUT

We tested the latest prototype which was successful. More tests are required to achieve complex results. The prototype has a high potential to perform complex foam extrusions and detailed milling.

FUTURE DEVELOPMENT

- Design unique materials with different densities and colors.

- Making architectural elements quickly.

- Printed foam sections are milled to achieve high-resolution output.

MULTITASK is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at

the Master of Robotics and Advanced Construction program in 2020/21 by:

Students: Arpan Mathe, Charng Shin Chen

Faculty: Angel Munoz

Faculty Assistant: Matt Gordon

https://github.com/MRAC-IAAC/MULTITASK-PU-FOAM-EXTRUDER-CNC-HARDWARE-I-SEMINAR