OTF December Presentation

On the 22nd of December, the student researchers of OTF presented their latest design proposal for the 3D Printed prototype using clay.

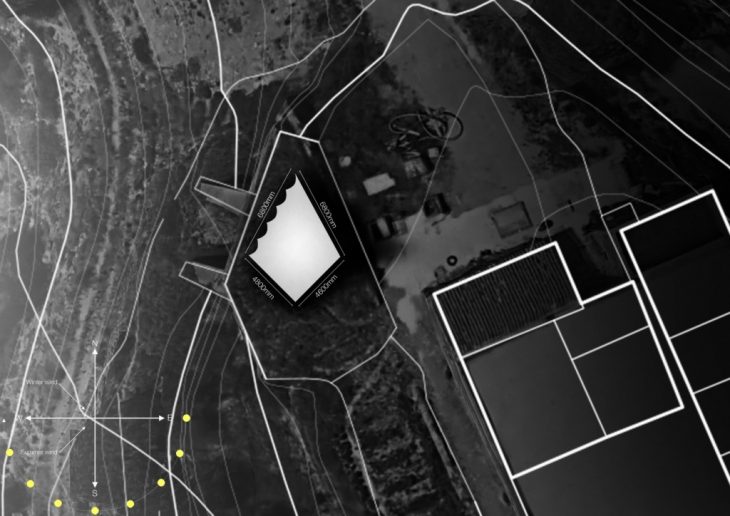

The team states the intention of the project, which is to combine the use of clay as a building material, 3D printing and on-site printing, a strategy which hasn’t been used before. The final prototype is to be located in the Valldaura Campus in Barcelona.

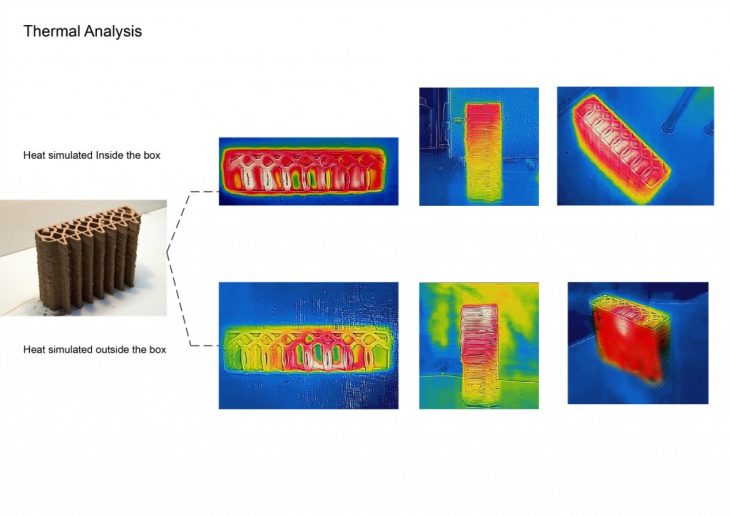

The main focus of this stage of the project development was simulating the proposals, in order to make sure the performance of the design is optimized. The simulations were both physical and digital.

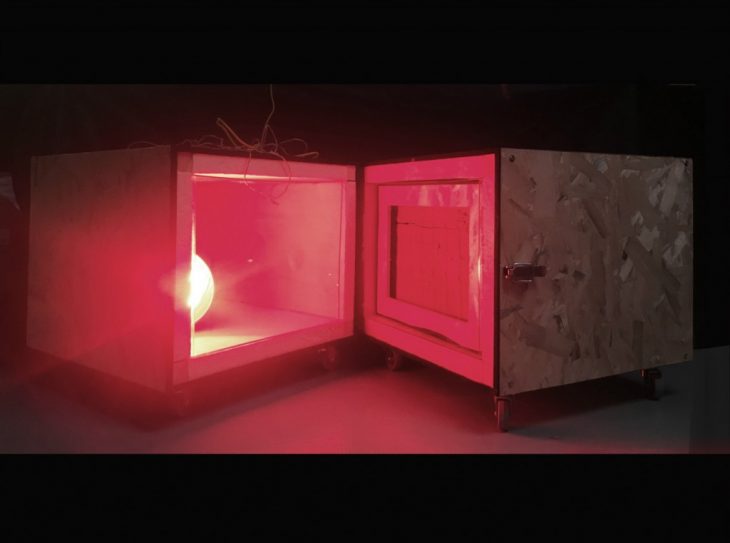

For the physical simulations, the students developed two machineries: a hydrothermal monitoring apparatus and a load machine. Additionally, they used the industrial robot to recreate the sun path, in order to analyze it.

The hydrothermal machine is divided into 2 sides: the left one is meant to be a simulated environment, in which heat is mimicked by an IR light. On the right there is a sensor places, which simulated environmental conditions of 40 Celsius Degrees, 5 hours at a time for each of the performative walls.

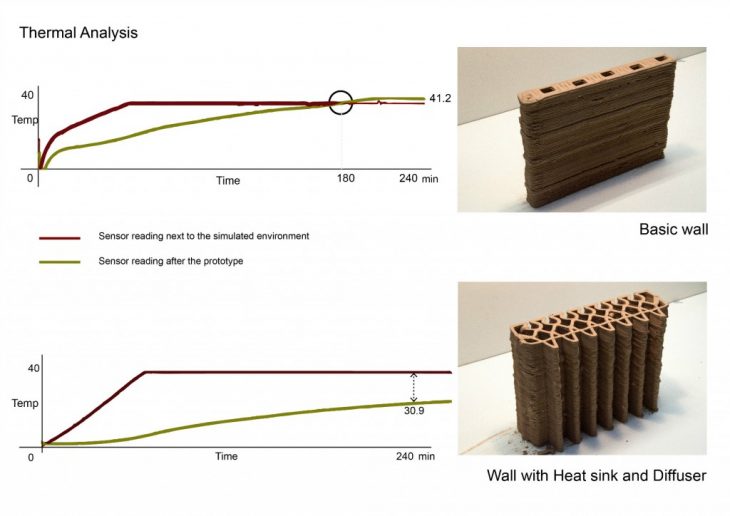

This helped drawing the conclusion that the longer the length of the curve, the more insulation it provides. After using the thermal camera to see the path of the heat, it was easy to deduct that a wall with optimum surface manipulation and longer infill curve length has more performance in terms of thermal mass and thermal conductivity, compared to a straight wall.

The graphs compiled data from the 2 sensors – one placed next to the simulated environment, and the other one placed next to the wall. The temperature difference is clearly noticeable, while the right wall blocks the heat by 10 degrees. The final simulation was adding phase changing material, such as was, which when 40 Celsius degrees were passed started to melt and started heating the wall.

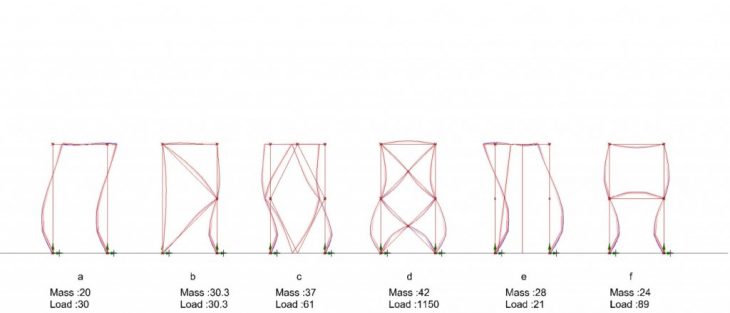

As for digital simulations, the software used consisted in Rhino CFD, Karamba. Lady Bug, Heliotrope and Autodesk Flow. Therefore, they were able to simulate wind and sun behavior and reparametrize their design accordingly.

Within the presentation, the student researchers also presented their formal proposal. Focusing on macro, meso and micro scale, the researchers developed an overall shape, as well as design details. The main volume is set to be a cube, since the biggest challenge within then program was to be able to print a series of straight walls, which would incorporate climatic performance, 3D Printing logic and take advantage of clay properties. Additionally, due to the performative aspects, the walls have very distinct visual appearance, which by an overall simpler shape would be counterbalanced.

Also, the students discussed their strategy for integrating openings within the volume, from bigger ones which will act as architectural traditional elements such as the door and the windows, to micro perforations which will aid the wind performance.