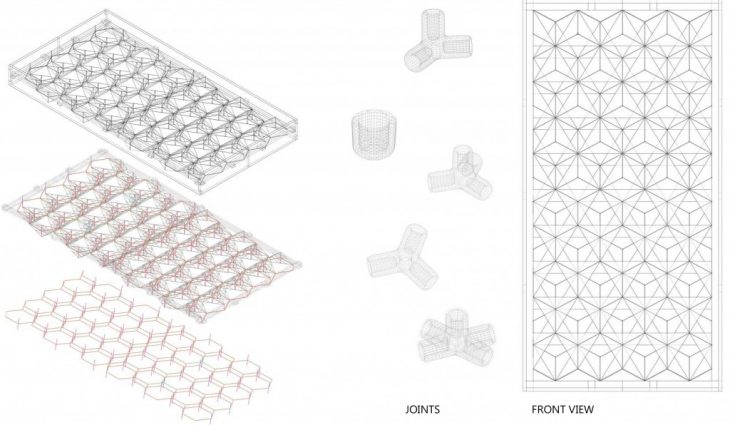

PARAMETRIC FRAME – 3D PRINTED JOINTS

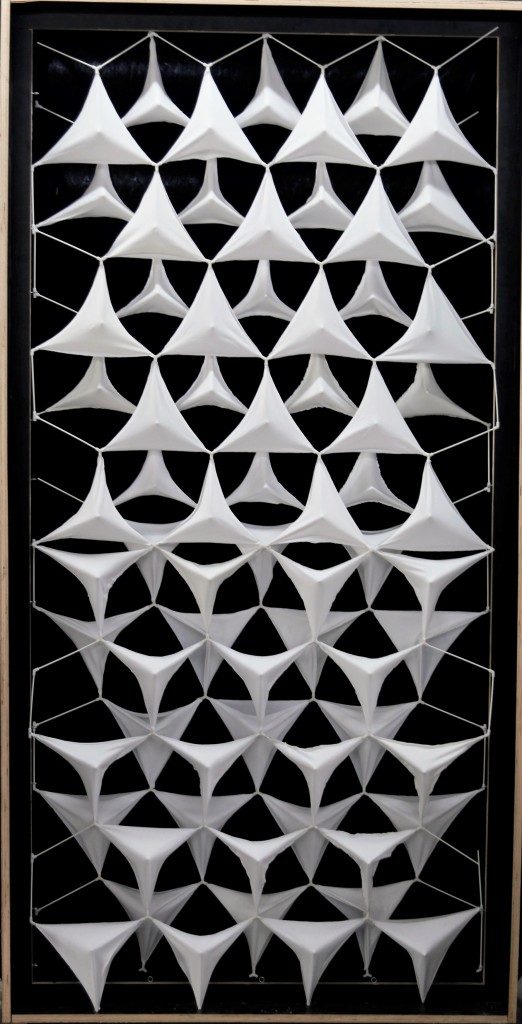

The Idea of this project is to explore the capabilities and limitations of the 3d printing manufacturing process and to develop an integrated approach to design and production. The goal of this exercise is to fabricate a space frame with 3d-printed structural nodes, that is then covered from both sides in an elastic fabric. Light sources has to be incorporated to create visual effects in combination with the structure and fabric.

Concept of the project is to incorporate triangular fabric on a hexagonal grid and play with the depth of the triangles. The project has a limitation of both size of the frame(1000mm x 2000mm) and a time limit of 48 hours(fabrication time).

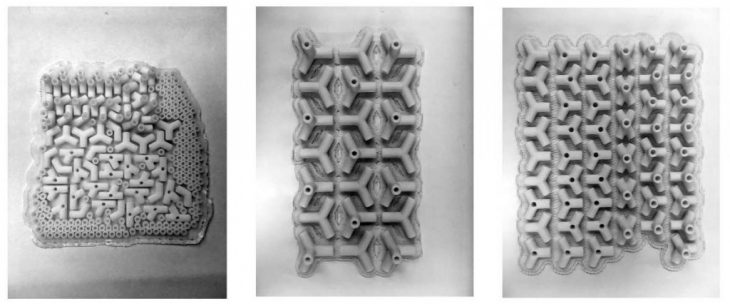

FABRICATION

MATERIAL USED:

- 255g Polyactic Acid (PLA) PRO

- 52 fiberglass rods 3 mm

- 5 sq/m white lycra

MACHINE USED – ZORTRAX M200

FABRICATION TIME: 38 Hours

DIGITAL FABRICATION PROJECT DEVELOPED IN IAAC BY MAA01 STUDENTS

Deepankar Pahuja , Elena Kavtaradze , Gabriele Jureviciute , Hari Krishna Gundu

Faculty : Alex Dubor , Raimund Krenmuller