BRIEF

The project aimed to fabricate a prototype of the “HexBox Canopy by DTC + CodeToProduction” facade system and explore the capabilities of manufacturing processes through the laser cutting machine. Project made in one week of the Digital Fabrication seminar at IAAC, Barcelona, 2020.

REFERENCE

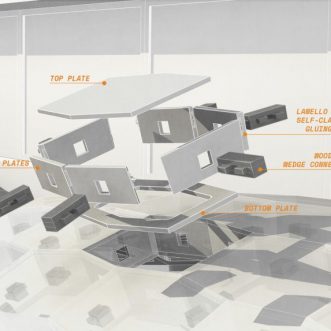

The HexBox, 45m² pavilion made by DTC + CodeToProduction in Darlington, Australia, 2019, is an investigation of assemblages of timber skin, made out of pre-fabricated squares plywood plates. The design looks to plan not only a pavilion that portrays the advances of digital timber construction, but at the same time, provide a space for student while covering them from sun and rain. With the inclusion of 1531 timber segments making up 201 boxes, the HexBox shell is materialized of plywood components without the incorporation of any detail fasteners for any load-bearing points in the structure.

RENDER

HexBox Canopy Facade System || Render by Uri Lewis

PROCESS

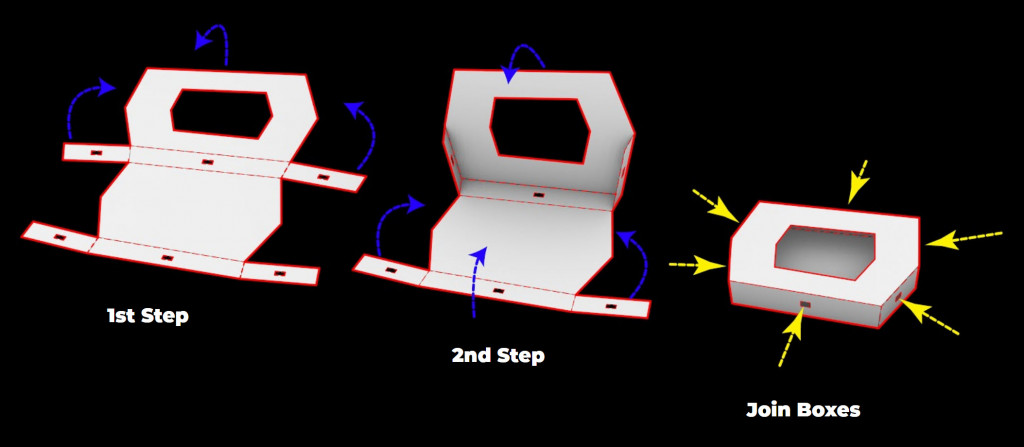

For laser cutting, angled joints were needed in the plates to replicate the original facade system so it wasnt suitable to use wood neither the same technique; in order to achieve a succsefull assambly an unrolling was performed to then engrave, cut and fold each box of the pavilion.

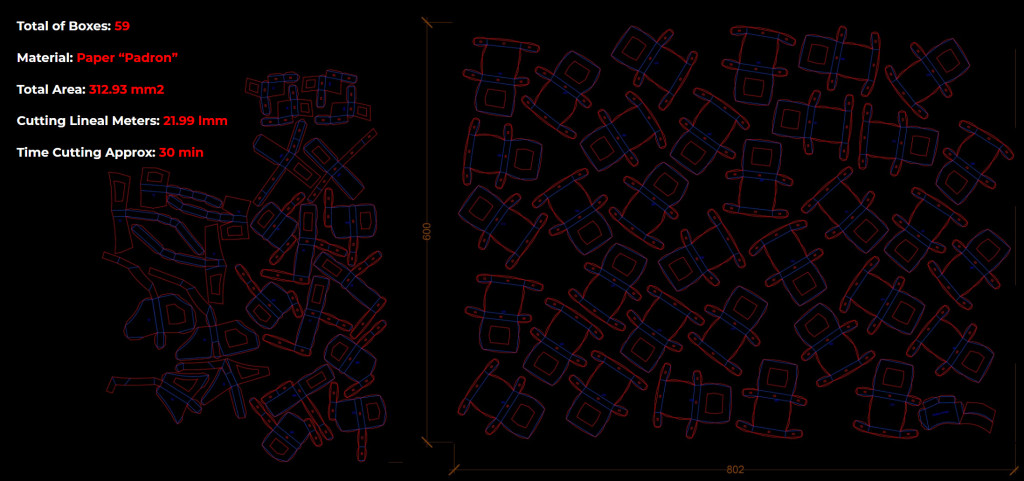

1 sheet and a half of 800X600mm ” Padron paper” was used to cut 59 boxes for the final assambly. The fabrication process took approximately 2 hours (30 min cutting, 1.5hr assamblying) and included some issues such as the folding in a rush is not a good idea for aesthetics, it was needed more tolerance for the extra material of the flaps while folding.

FABRICATION STRATEGY

Assambly Process

PRODUCTION DATA

Pieces Layout

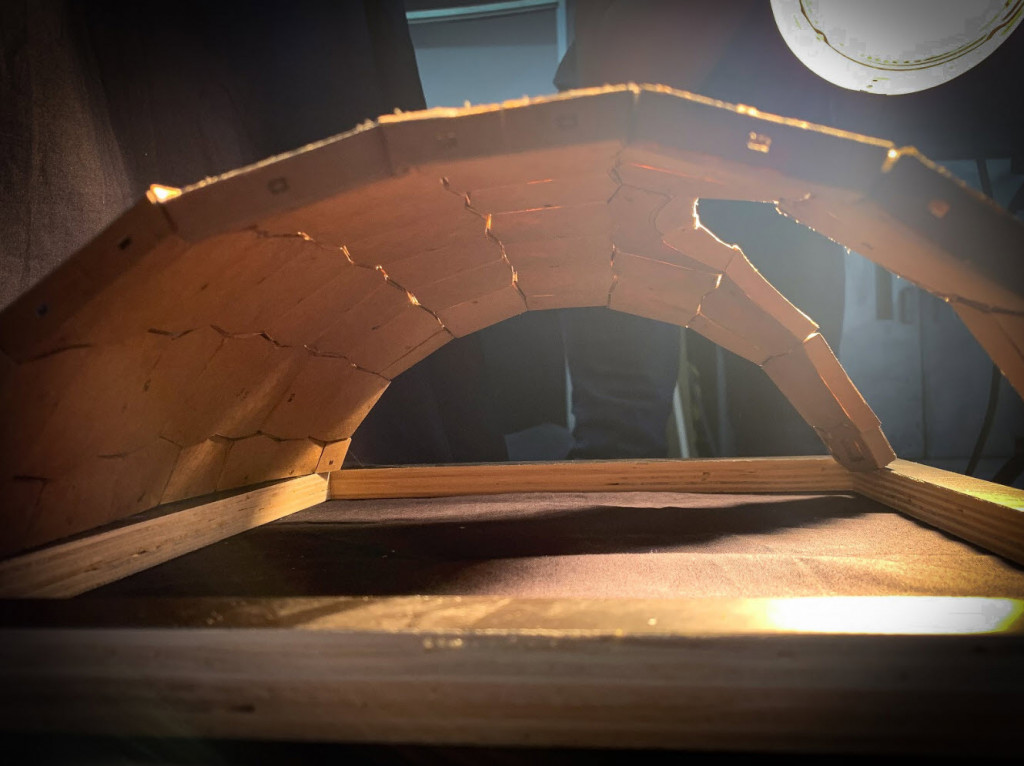

FINAL MODEL

HexBox Prototype_01 Perspective

HexBox Prototype_01 Right View

HexBox Prototype_01 Perspective 2

Parametric Skins // HexBox Canopy in Laser Cutting is a project of IAAC, Institute for Advanced Architecture of Catalonia developed in the Master of Advanced Architecture 2020/21

by Student: Uri Lewis Faculty: Ricardo Mayor Luque, Lana Awad and Shyam Zonca