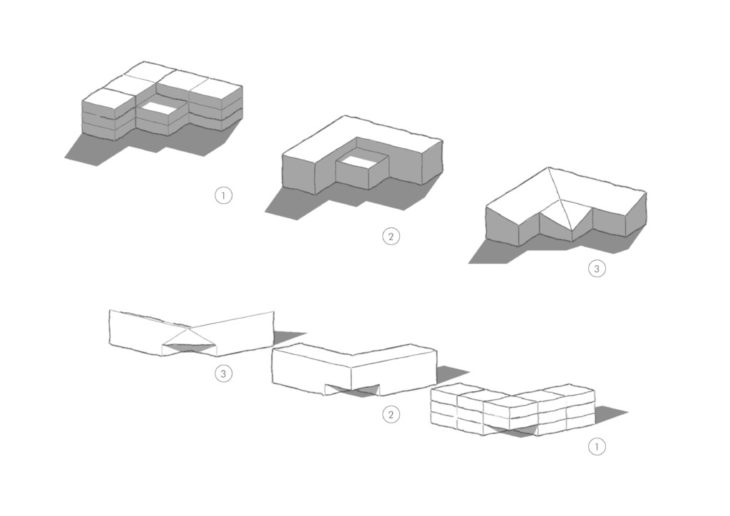

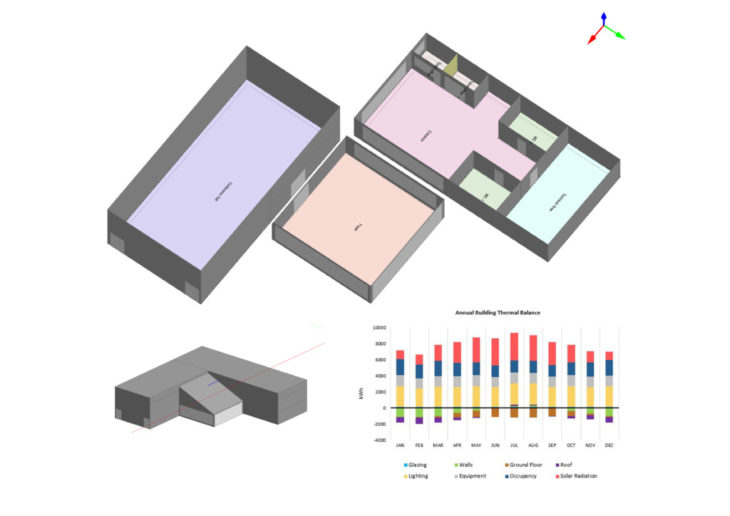

VOLUME CONFIGURATION AND CLIMATE SELECTION

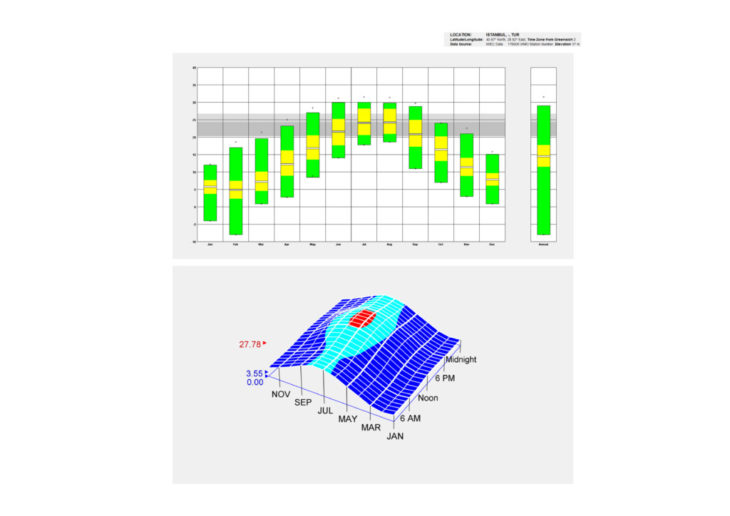

The volume configuration consists of Type A volumes (from Module 1 and 2)which are 10m x 10m units stacked together to create an industrial-scaled building. The site chosen for this project is Istanbul Turkey, where the summers are warm, humid, and clear and the winters are long, cold, windy, and partly cloudy. The temperature is rarely below freezing. The hottest month of the year in Istanbul in August, with an average high of 28C.

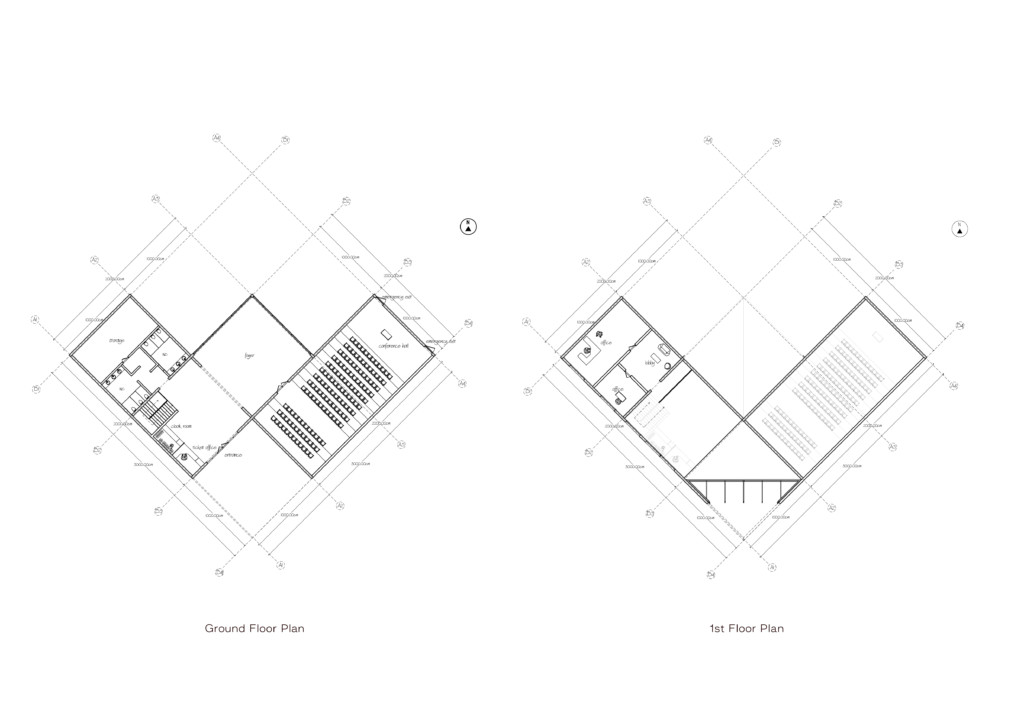

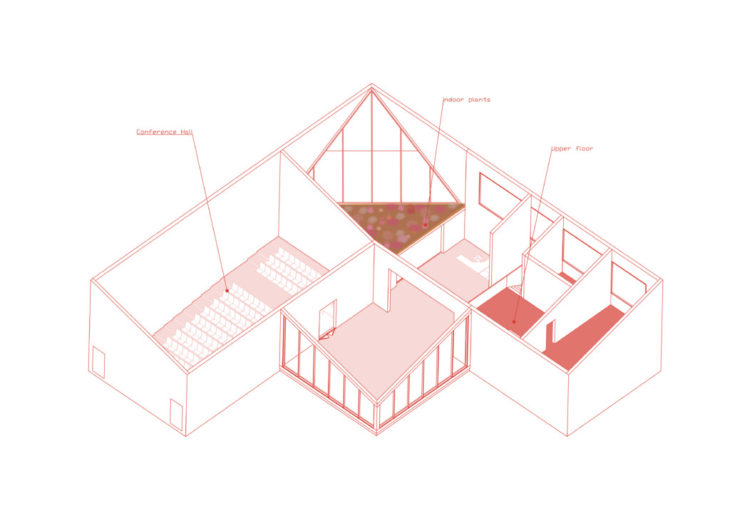

The building consists of a conference hall, a foyer, service areas, and office spaces. The foyer faces the south and has a glazed facade to benefit from solar radiation in the winter and sunlight throughout the year. The entrance is shaded by the roof overhang, and the interior space of this overhang is utilized as a planter. The office spaces and the entrance hall are also illuminated by the openings facing the north facade.

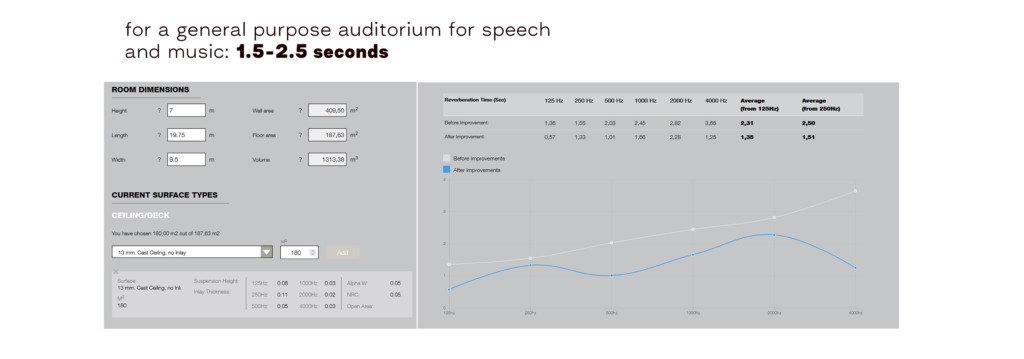

BASIC ACOUSTIC DESIGN AND PERFORMANCE CALCULATIONS

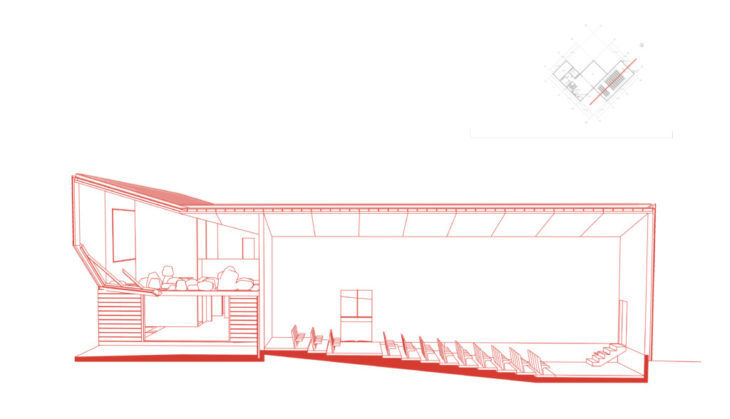

Section of the Conference Hall

For the next step of the coursework, the acoustic design of the conference hall was to be developed. Using the calculator available on DAMPA website and entering information such as the dimensions of the space and the materials used in the room, the reverberance rate of 2.5 was achieved. With additional products of DAMPA for the walls and ceilings, this rate could be even lowered to 1.5 seconds.

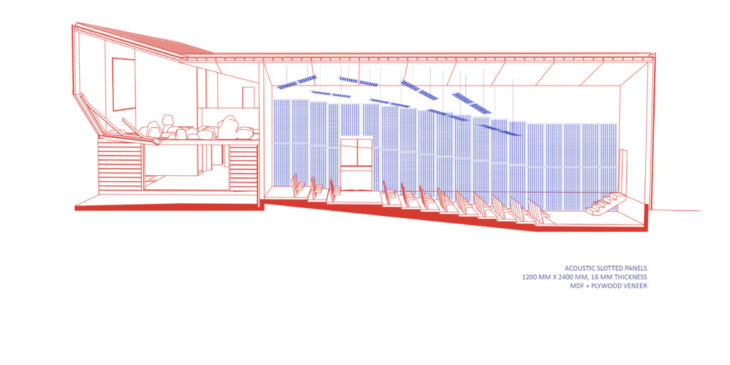

Instead of using DAMPA’s products, an MDF acoustic panel with a plywood finishing surface was selected for the design. These panels would be used on the walls vertically covering a 4.8-meter height and 1.2 meters wide. The floors are covered with wood and linoleum.

Section of the Conference Hall with Acoustic Panels

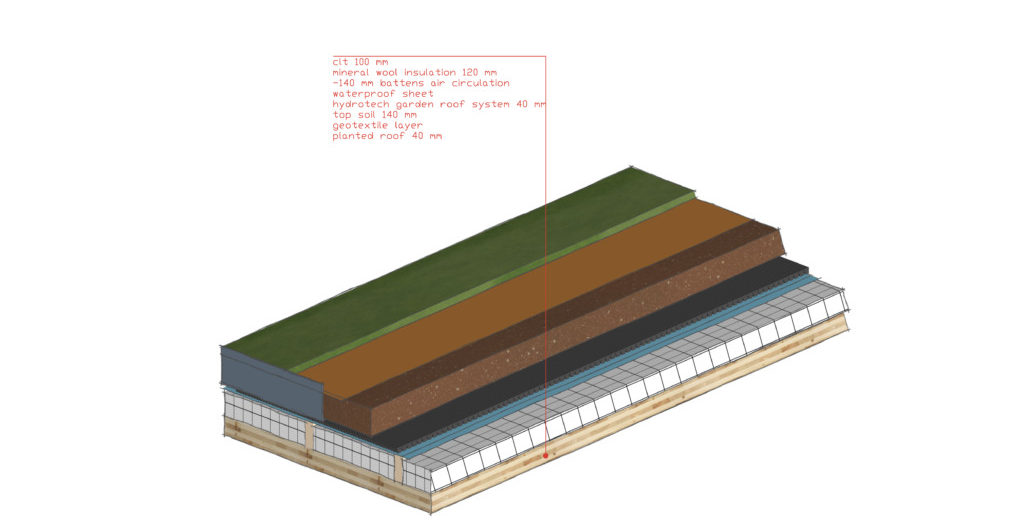

GREEN ROOF DESIGN AND WATER CONSUMPTION CALCULATIONS

Extensive Green Roof Layers

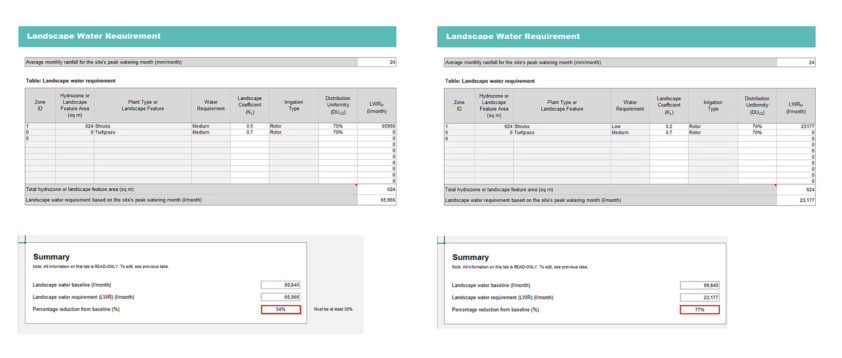

The 624 m2 extensive green roof consists of 7 layers including a CLT structure. For the vegetation, a native species to the climate with minimum water requirements, Stonecrop was selected. For the baseline calculation, the data for the driest month – which is August- is preferred. By calculating the water demand for August, and selecting medium water requirement as an option, the estimated liters per month is around 66.000 L. Since Stonecrop doesn’t require an extensive amount of water, in the second calculation water demand was switched to low rather than medium. With this change, the reduction achieved is by %70.

Water Requirement Calculations

The last stage of the coursework was to simulate the energy performance of the building using Designbuilder software. The initial step was to model the building and define the different thermal zones, enter the climate and location information, and specify the construction data such as where the openings will be, what type of materials the walls, floors, and roofs consist of, etc. Within each thermal zone, information such as occupancy, lighting preferences, HVAC systems, glazing options, etc. have to be decided to calculate the energy requirements and consumption. Once all the necessary information is determined, the design simulation is executed. The results of this simulation constitute the baseline case for this study.

Baseline Case

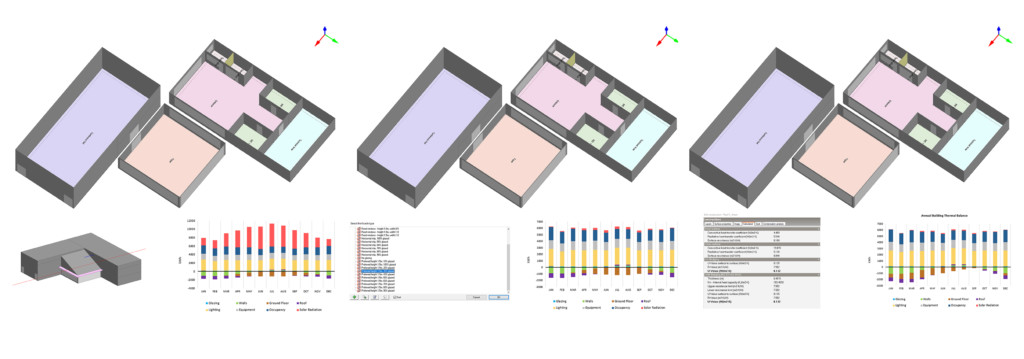

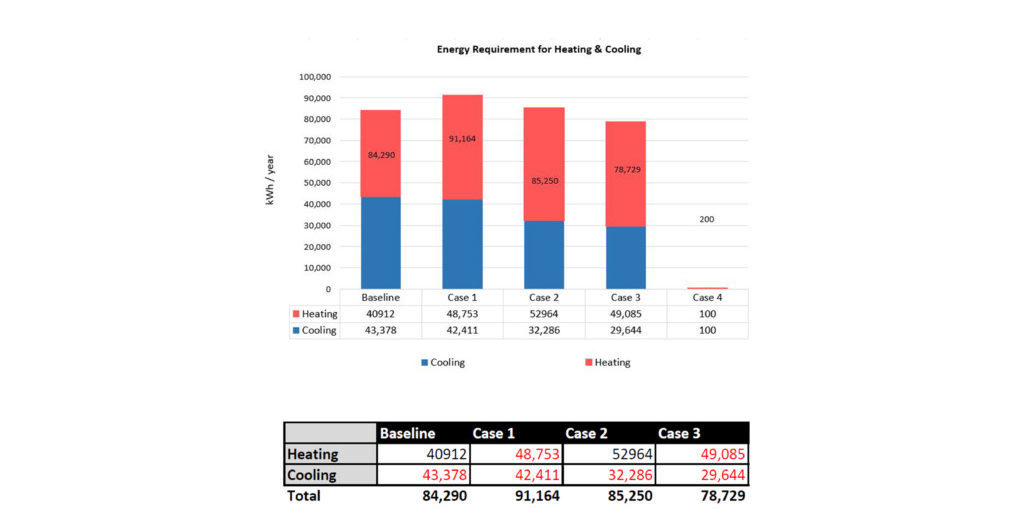

For Case1, Case2, and Case3, various things in the model were modified to see the results change. For example, in Case 2, the number of openings in the walls was changed to 30% which increased the surface area of the openings. Therefore, the cooling energy demand decreased, but the overall energy requirement increased because of the heating needs. In case 3, with the improvement of the roof insulation therefore the U value optimization, the total energy requirements diminished.

Graphic Representation of the Comparisons

Conference Center Performance Design Studio is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at Master in Mass Timber Design in 2021/2022 by Student: Esin Zeynep Aydemir. Faculty: Patrick Spencer. Course: Techniques 3.2