Phriends* for Shells, the Master in Advanced Architecture’s Seminar in Advanced Robotic Fabrication, we fabricated earthen shells establishing perforations and non-uniform thickness, under the supervision of Innochain PhD Candidate Stephanie Chaltiel.

Phase I Construction of Shell. The nodal point projections rise up to add local stiffness that gives additional strength to the adjacent surfaces. Distortion at the footing to the both the shell form and the structural formwork locks in stiffness distributing different forces across the surface acting as a core.

Phase II Perforation Logic. The initial projection’s for the perforation where designed to create tension between the reed branch formwork and the elastic fabric sheeting – preventing excessive sagging of the fabric following the application of sprayed mud layers.

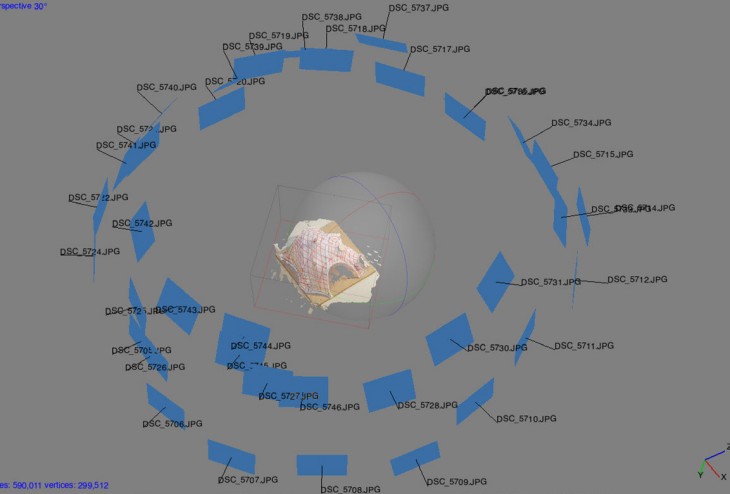

Phase III Scanning of Construction. On completion of the constructed piece we used a scanning software (Agisoft) to form a digital replication of the structure. This process is repeated following each application of clay mixture.

Phase IV Kuka & Mud Spray Mixtures. We explored various mixture ratios of earth to water, and stabilizer (Jute fabric) acting as reinforcing.

Phase V Robot-Spray Trajectory. Changing the trajectories of the model and the actions of the spraying apparatus to alter the thickness on the material around the corrugations to exaggerate the vein quality of the structure.

Phase VI Waterproofing and finalizing the shell

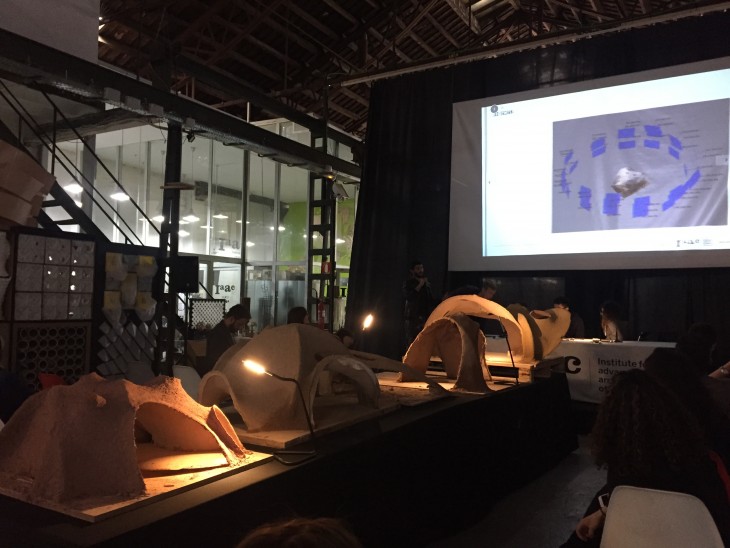

Final Presentation of Students Shell Structures at the IAAC Auditorium

Phriends* for Shells Seminar

Phriends* for Shells Seminar

A project of IAAC developed by;

Robert Staples | Fabiana Nacife | Fernando Castilho | Fabio Della Barba Menezes | Catherine Simakova, with the MAA001 2016. All Rights Reserved.