AIM

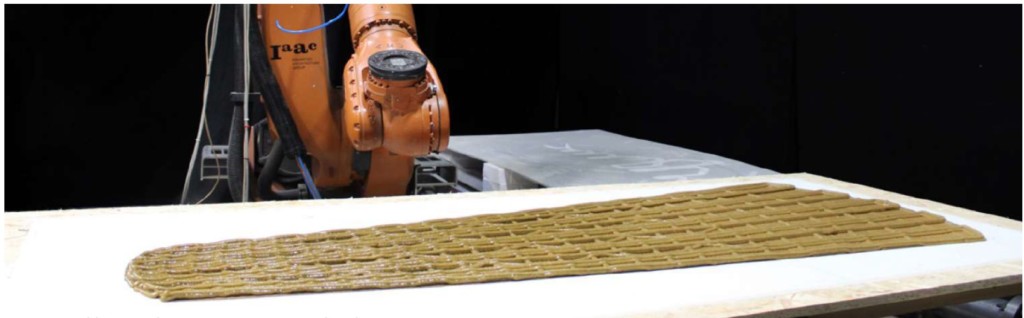

Pleats of Matter aims to robotically 3d print a seaweed-based bioplastic bringing shrinkage and self-deformation into the design process in order to achieve large scale production.

FRAMEWORK

The research is framed within three Sustainable Developments Goals (SDGs) adopted by the United Nations in 2015 as a global call to action to prevent and preserve the environment.

OBJECTIVES

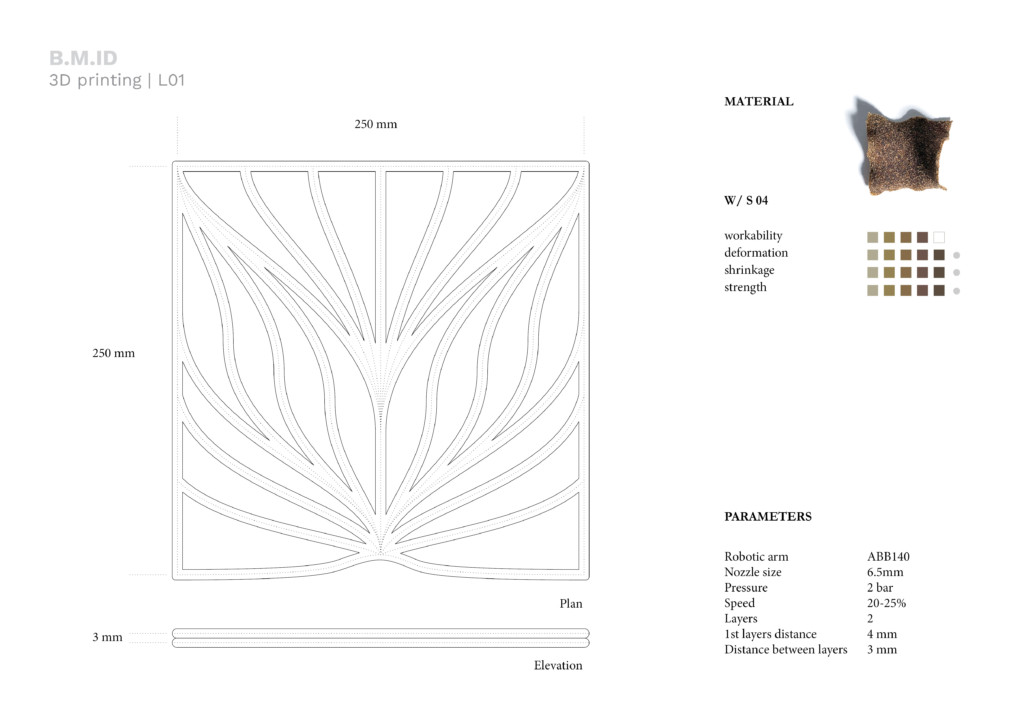

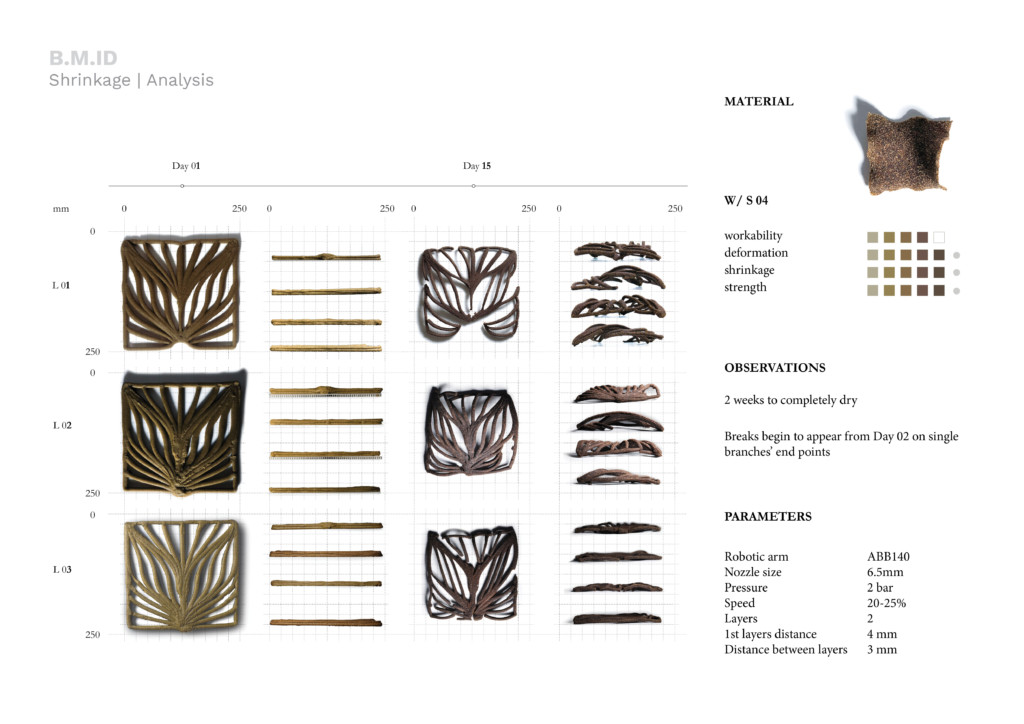

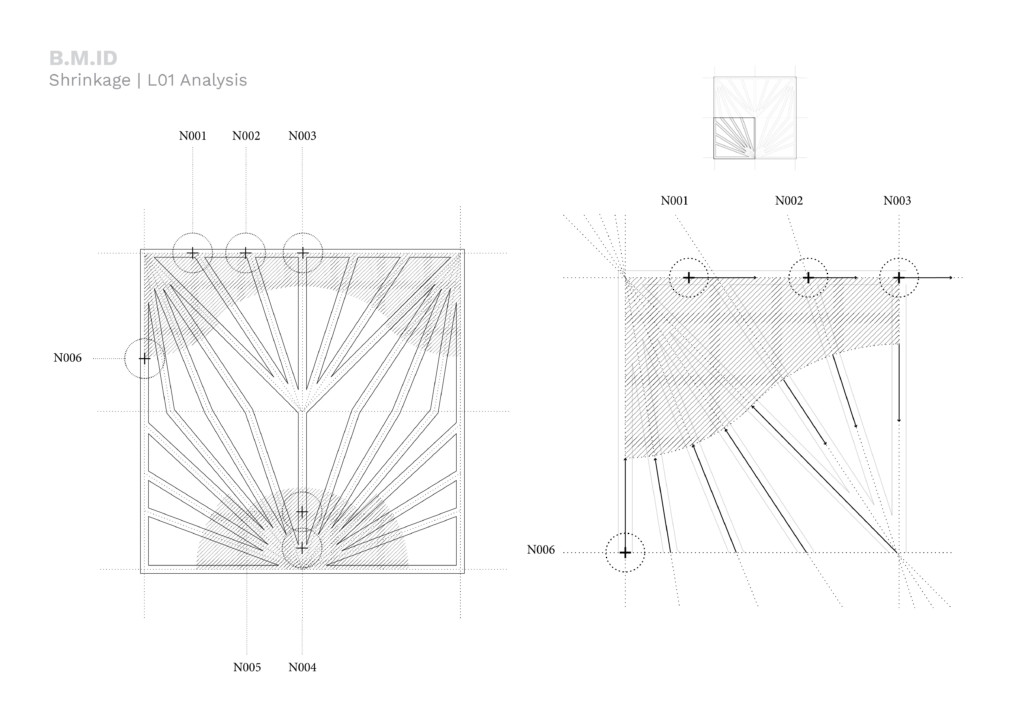

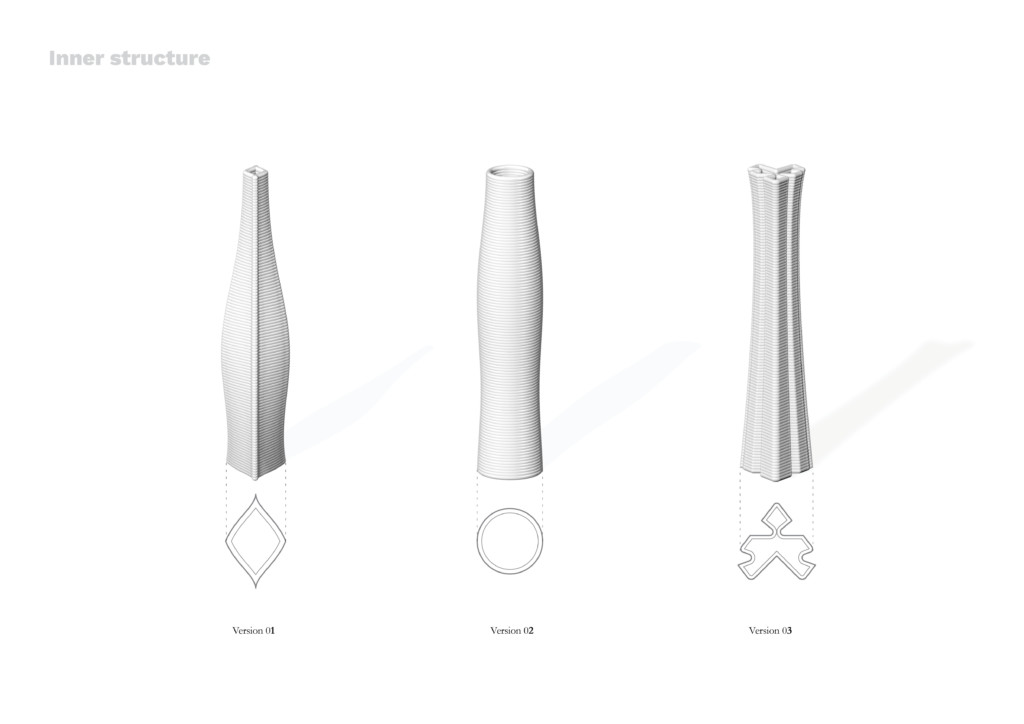

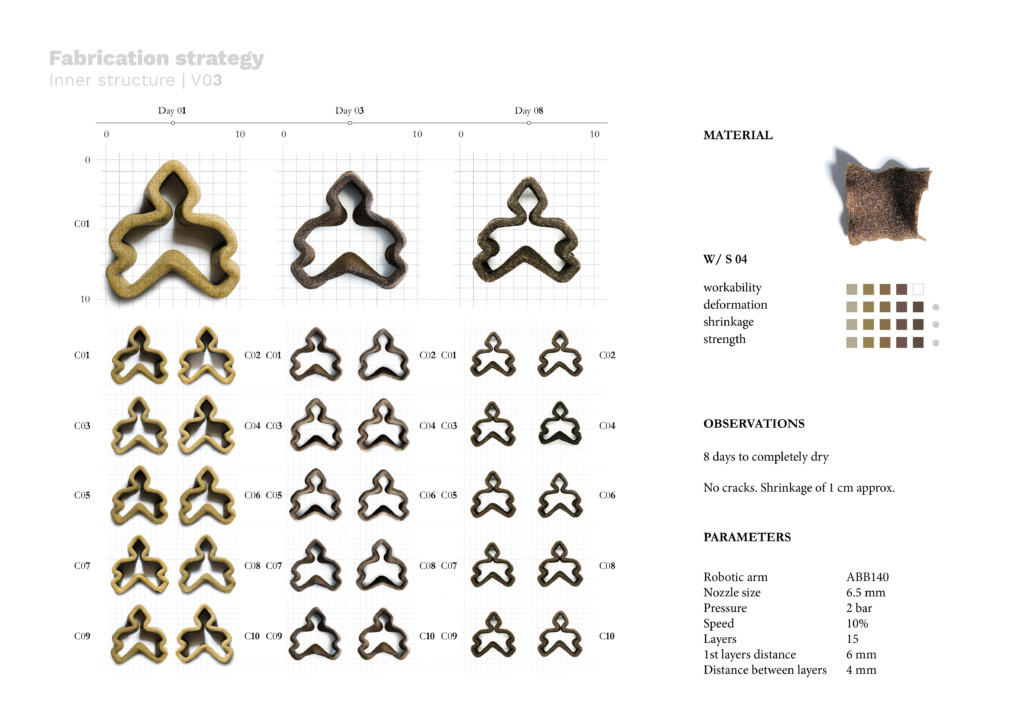

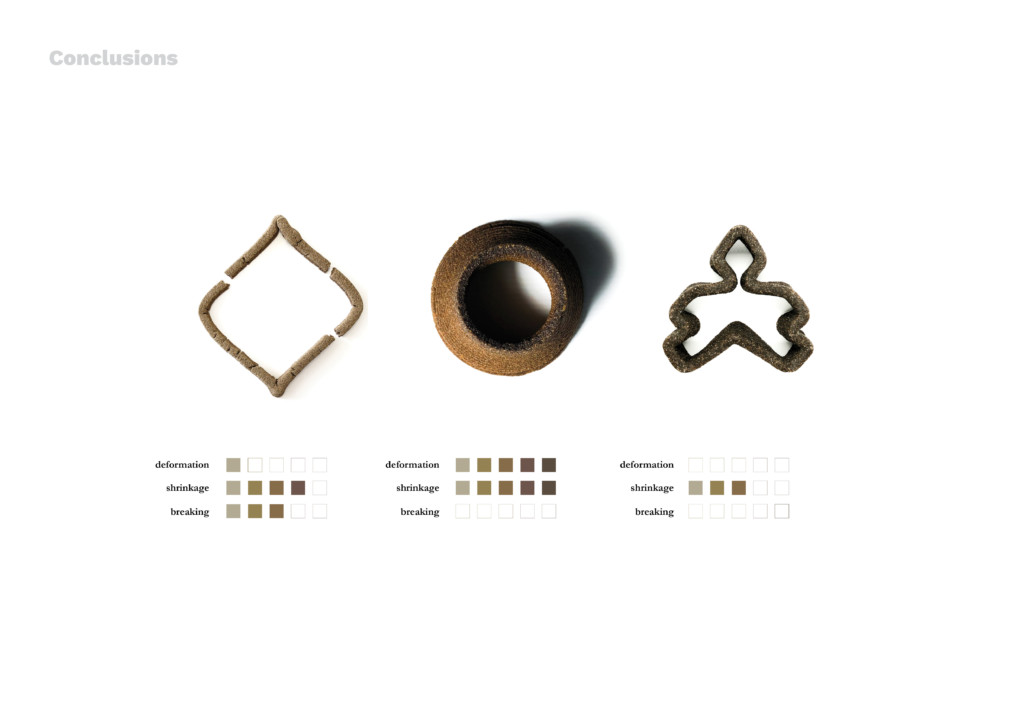

The first objective of the research is to analyze the material’s physical properties and behavioral performances through small-scale manual experiments to achieve a material that better fits the robotic fabrication requirements. Secondly, develop small-scale robotic prototyping to understand if shrinkage and self-deformation can provide unforeseen solutions when brought into the digital fabrication process. Finally, to set up a fabrication process integrating material’s behaviors to achieve large-scale production.

WHY 3D PRINTING

3D printing offers several advantages compared to traditional manufacturing methods. To begin with, it provides high-resolution gradients of material distribution. Moreover, it allows to minimize material waste and speeds up the prototyping process.

BIOPLASTIC

The research focuses on developing seaweed-based bioplastic as an alternative to synthetic materials.

Bioplastic consists of biopolymers, plasticizers, additives, and a solvent to provide the material with strength, flexibility, and texture. The materials used in this research were: alginate, glycerine, cellulose, sand, and water.

SEAWEEDS

Source: www.blog.geiworks.com

Seaweeds are marine plants that grow in water bodies such as oceans, lakes, and rivers and play a major role in terrestrial and marine ecosystems. Nevertheless, stranded seaweed poses severe threats to the environment. When seaweeds decompose, they emit toxic hydrogen and sulfide fumes which are harmful to human health and cause fish kills, die-off of seagrasses, and corals along the shores.

Increasing nitrogen and carbon footprint are the interlinked factors fueling invasive seaweeds species to bloom excessively, and many shores worldwide face the consequences. Thus, the challenge is to develop methods to reuse invasive seaweeds that affect the environment by looking at them as a renewable and biodegradable resource that can provide solutions to reduce waste, prevent and reduce marine pollution and reduce invasive species impact.

STATE OF THE ART

Seaweeds already serve as a source of raw materials for stabilizers or thickening and gelling agents, such as alginate. However, research is also increasingly interested in their potential as a source for bioplastic development as an alternative to synthetic materials.

Amber Laminaria – Photo credit: Ilaena Mariam Napier

Amber Laminaria, a project of IAAC developed in C-Biom.A Thesis Studio by Ilaena Mariam Napier in 2020/21 explores seaweeds’ physical and mechanical properties as a biocomposite material that can be 3D printed in large-scale sheets. The project aims to develop more sustainable manufacturing processes using seaweeds as a biocomposite material and provide solutions to the problem of material waste.

Hidaka Ohmu – Source: www.aalto.fi

Hidaka Ohmu, by Julia Lohmann, is a call for urgent changes to address the climate crisis. It investigates the potentials of algae as a biomaterial as an alternative for leather, textile, wood, paper, and plastic.

Bio-Concretion – Source: www.iaacblog.com

Bio-concretion, a project of IAAC developed by Tobias Grumstrup Lund Øhrstrøm, showcases the possibilities of seaweeds being integrated into an architectural system by combining old thatched roof technology and digital fabrication and computational design tools.

EXPERIMENTS

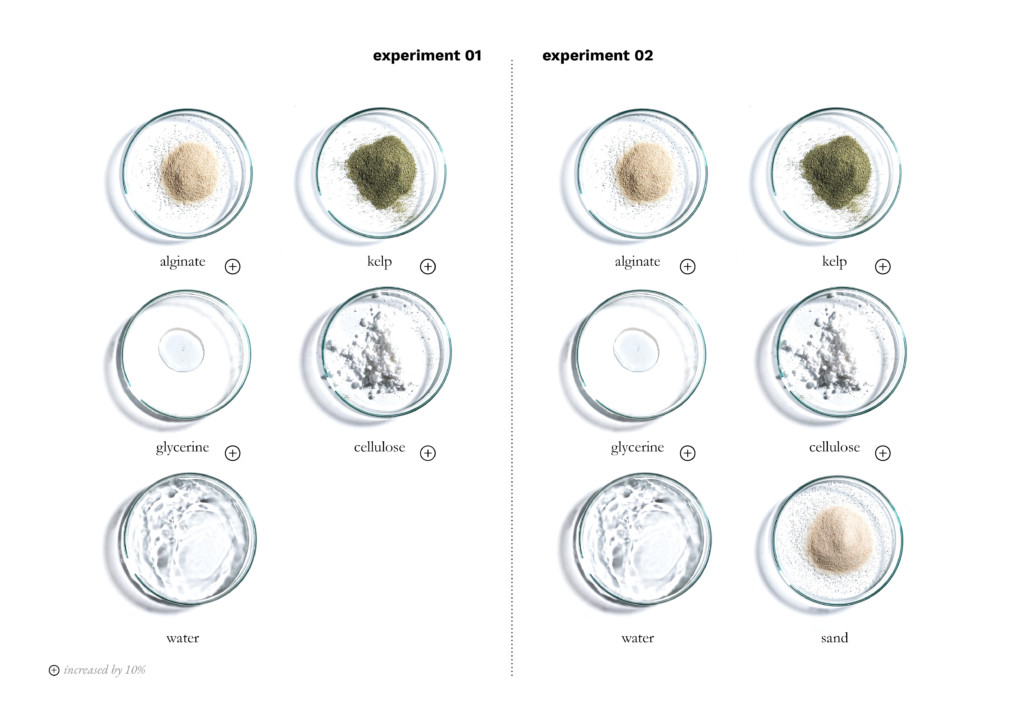

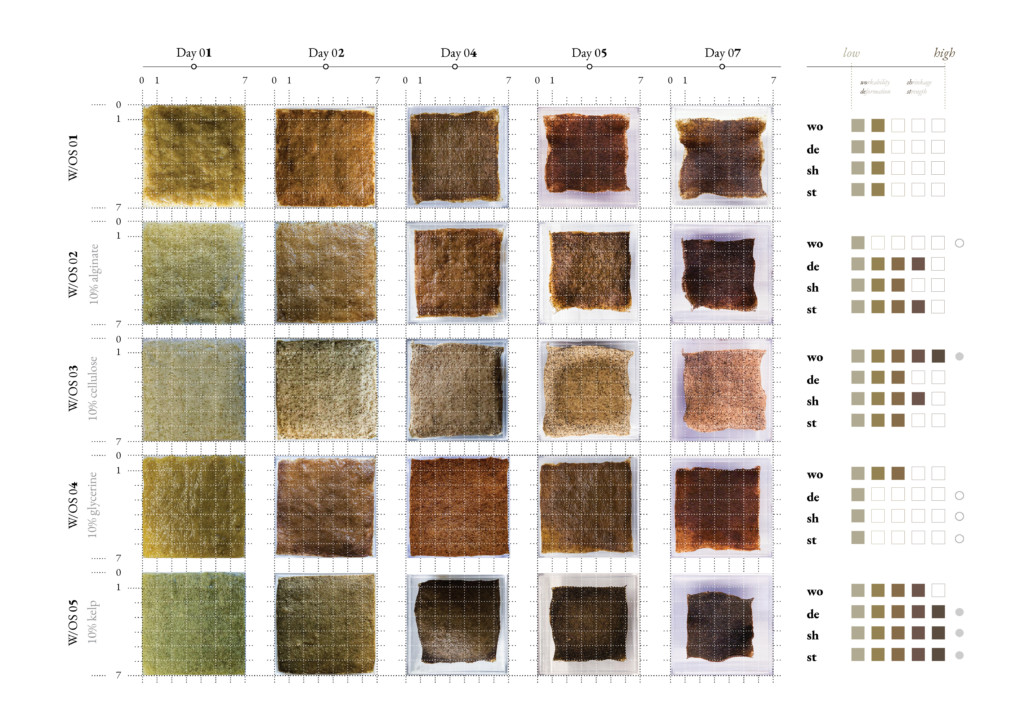

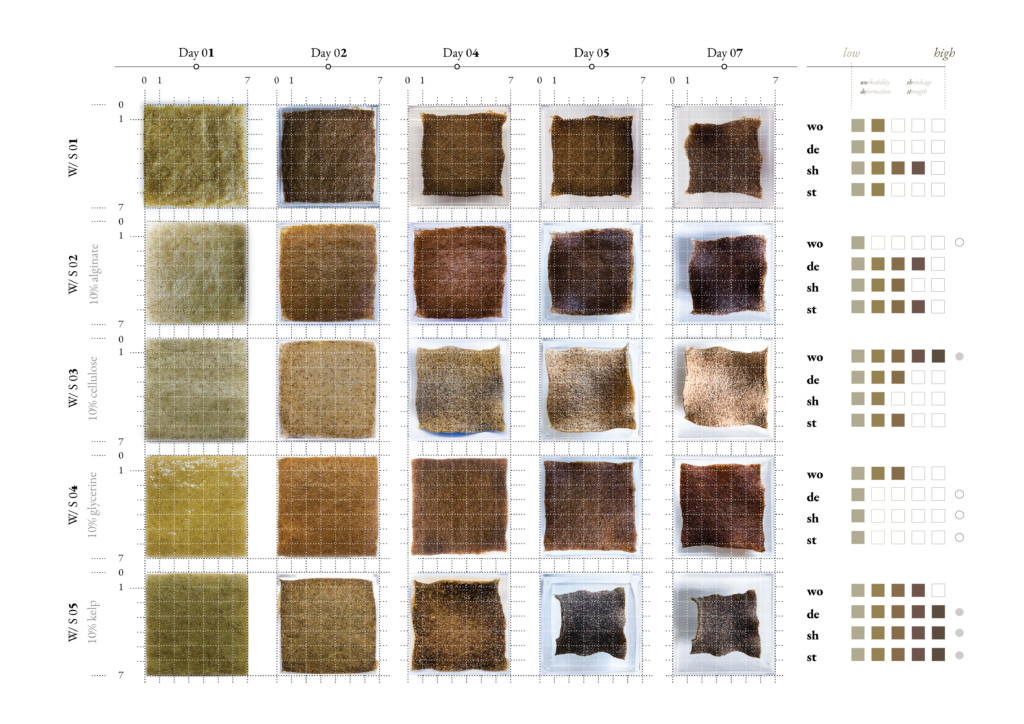

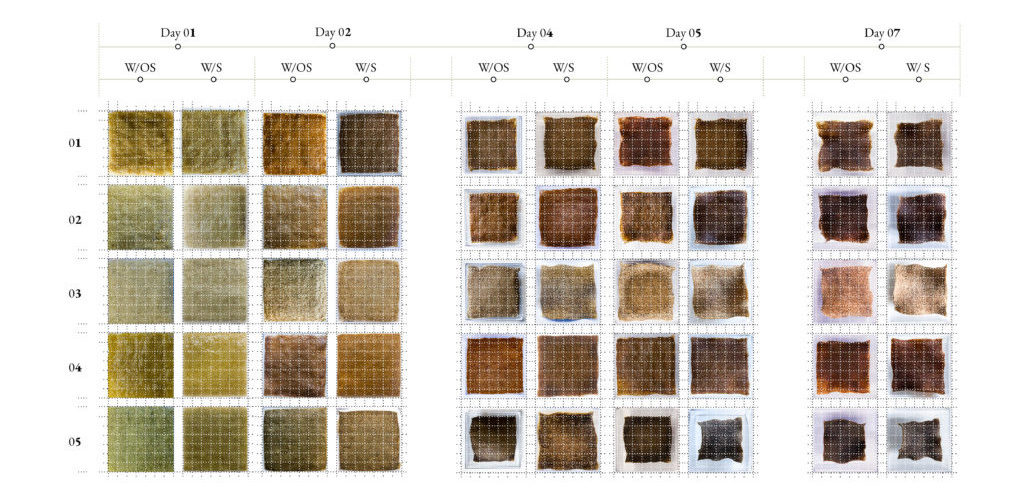

The research started by analyzing the material through small-scale experiments to gain knowledge of its physical properties and behaviors.

Each material was increased by 10 percent in each experiment to understand how they affected the material’s performance. In this way, five different samples were obtained for each experiment. In the second experiment, sand was added to improve the material’s strength.

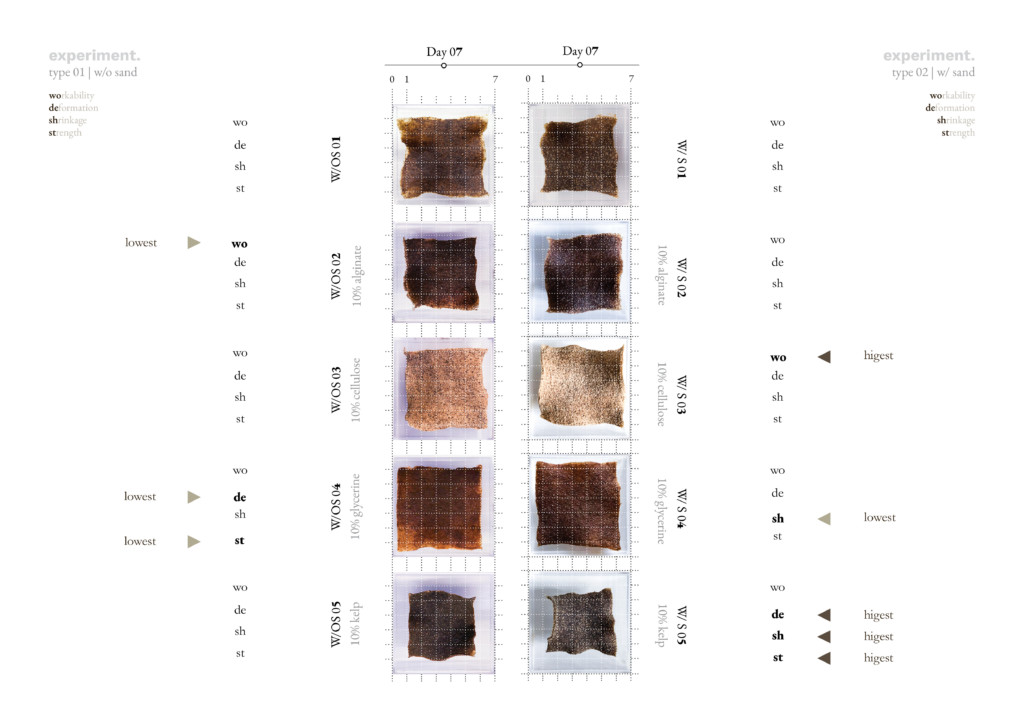

Finally, the sample with ten percent of kelp and sand showed the highest shrinkage, deformation, and strength values, better fitting the robotic fabrication requirements.

EXPERIMENT 01

EXPERIMENT 02

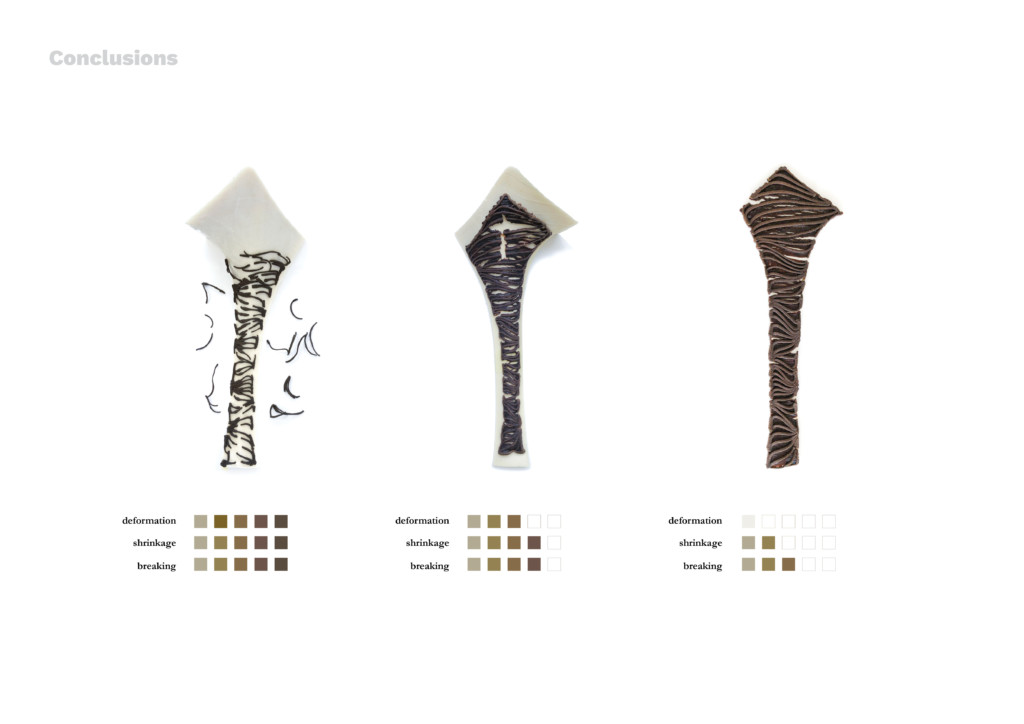

COMPARISON AND CONCLUSIONS

DEFORMATION

Matter expresses itself by deforming

Photo credit: Elena Petruzzi

can we take advantage of its deformation instead of controlling it?

Photo credit: Elena Petruzzi

The term deformation comes from Latin deformare meaning “transformation, distortion, disfigurement”.

Fan palm – Photo credit: David Clode / Petersen Automotive Museum – Photo credit: Ricardo Gomez

Deformation is also folding, an essential part

of nature and manufacturing which allows to achieve balance between flexibility, rigidity and strength.

RESEARCH QUESTION

Can deformation become part of the design process ?

REFERENCE

During the baroque period, deformation became part of the architectural design process. Going in opposition to the rigidity of the straight lines of the renaissance, baroque broke the rigidity of matter, creating illusions that deformed the perception of the space by using curves and irregular geometries in a succession of concave and convex conformations

Sant’Ivo alla Sapienza, Rome

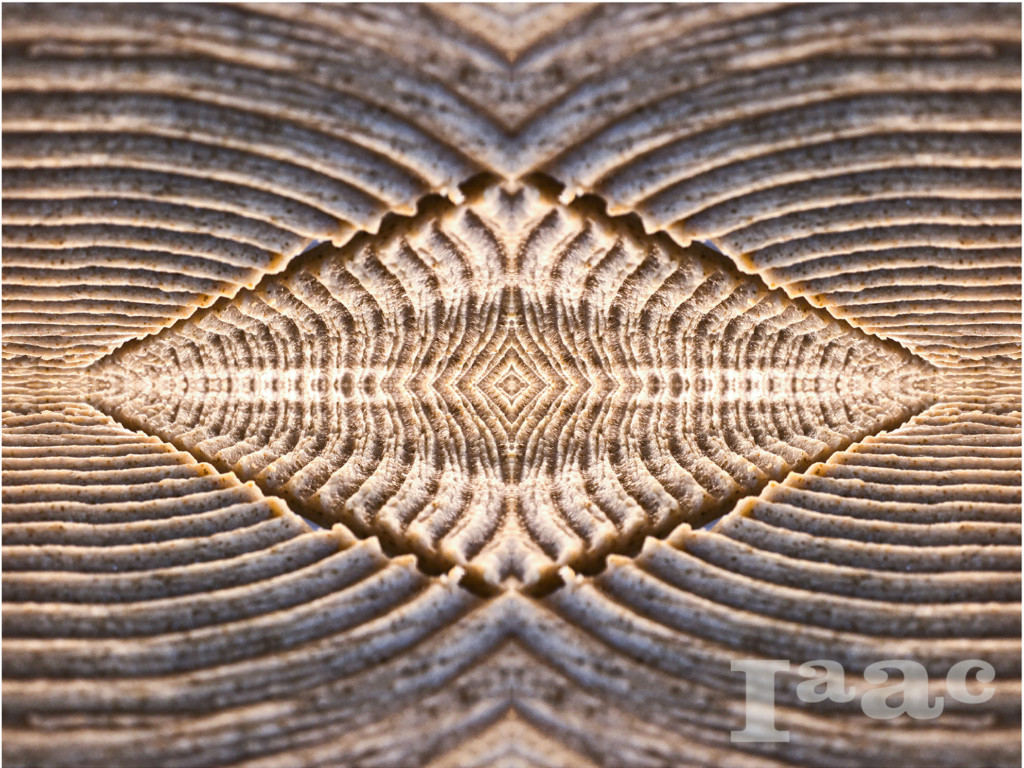

VISUAL EXPERIMENTATIONS

Photo credit: Elena Petruzzi

Photo credit: Elena Petruzzi

Photo credit: Elena Petruzzi

Photo credit: Elena Petruzzi

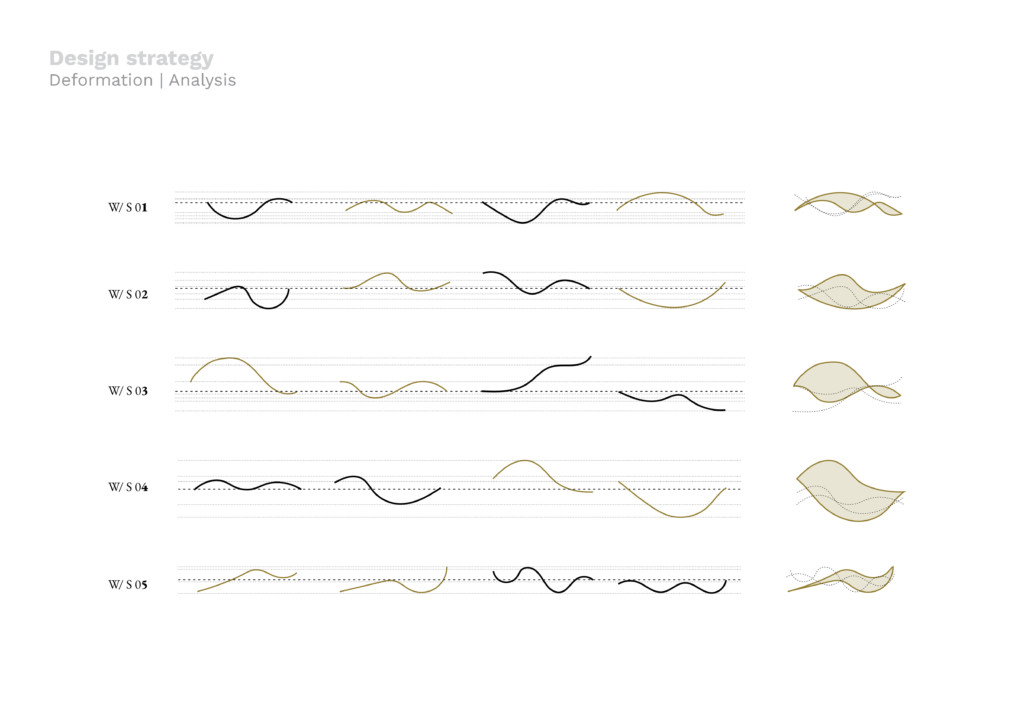

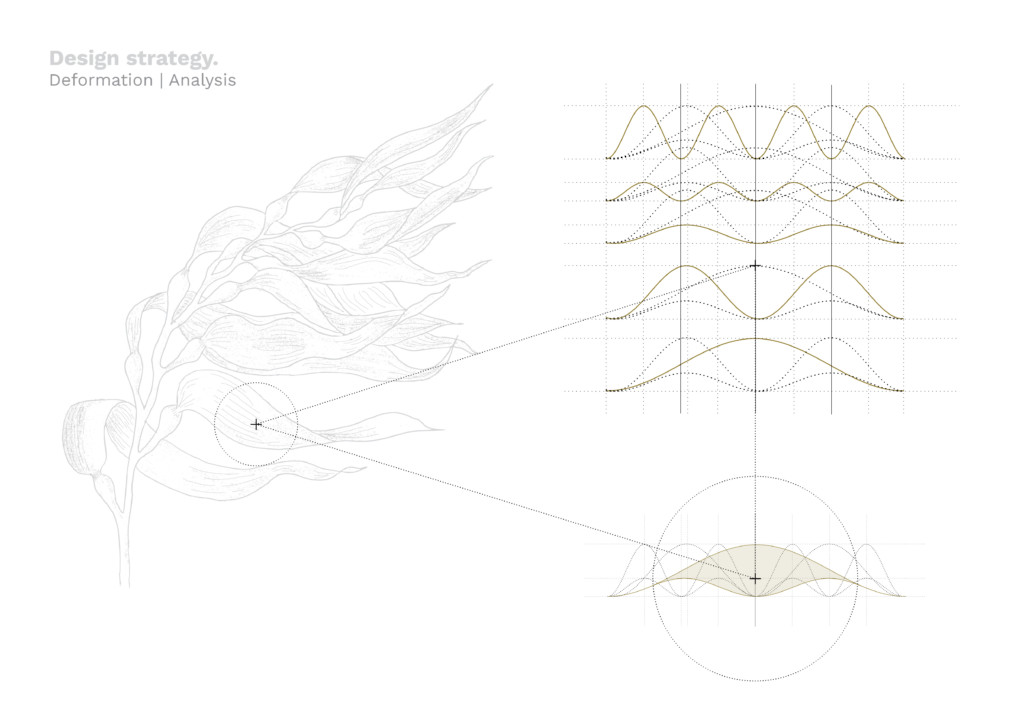

DESIGN STRATEGY

BIO-INSPIRED & MATERIAL-INFORMED DESIGN

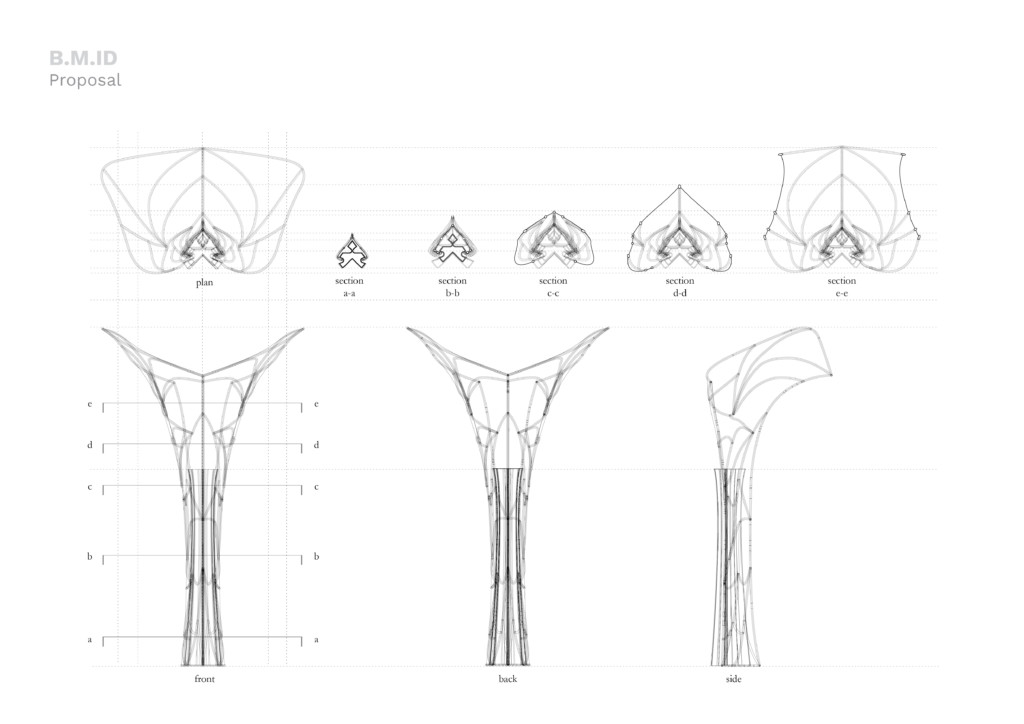

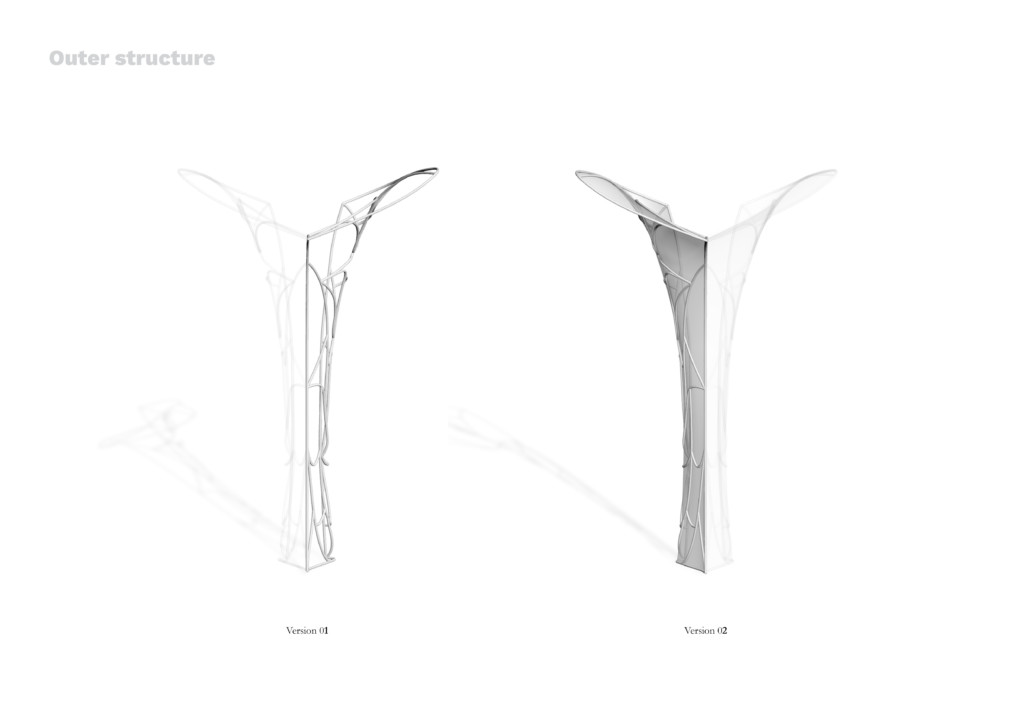

DESIGN PROPOSAL

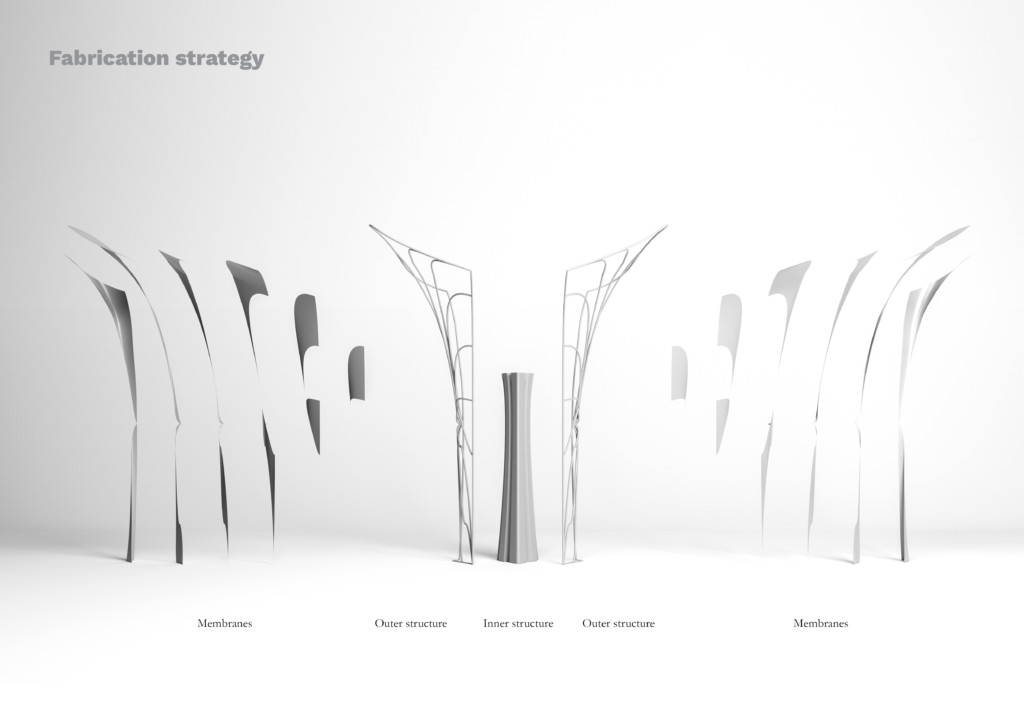

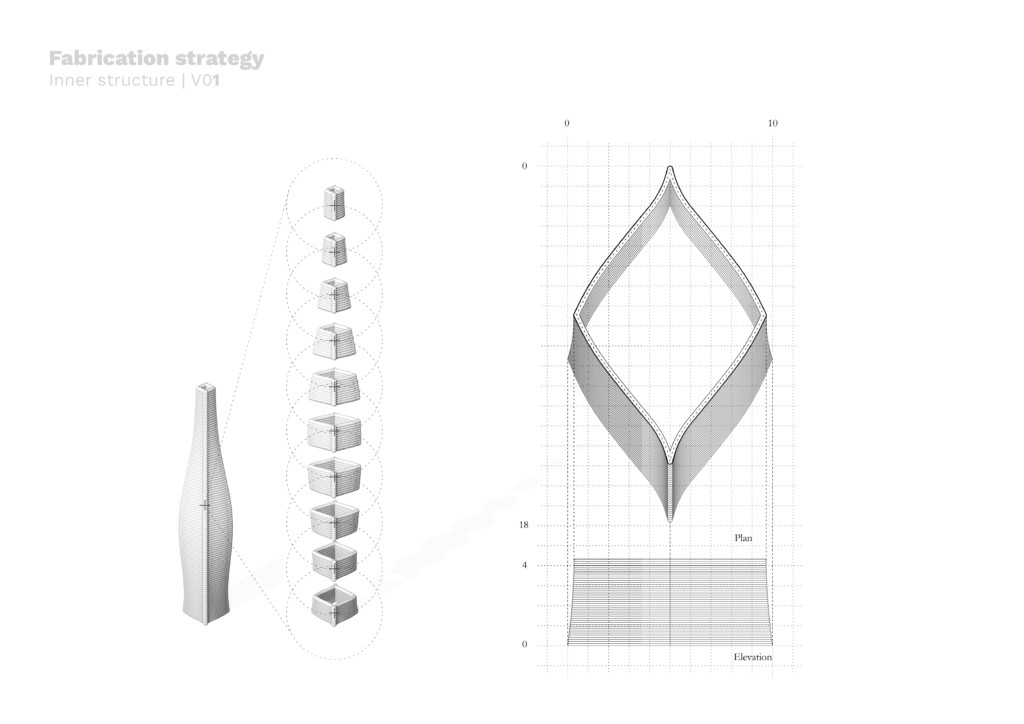

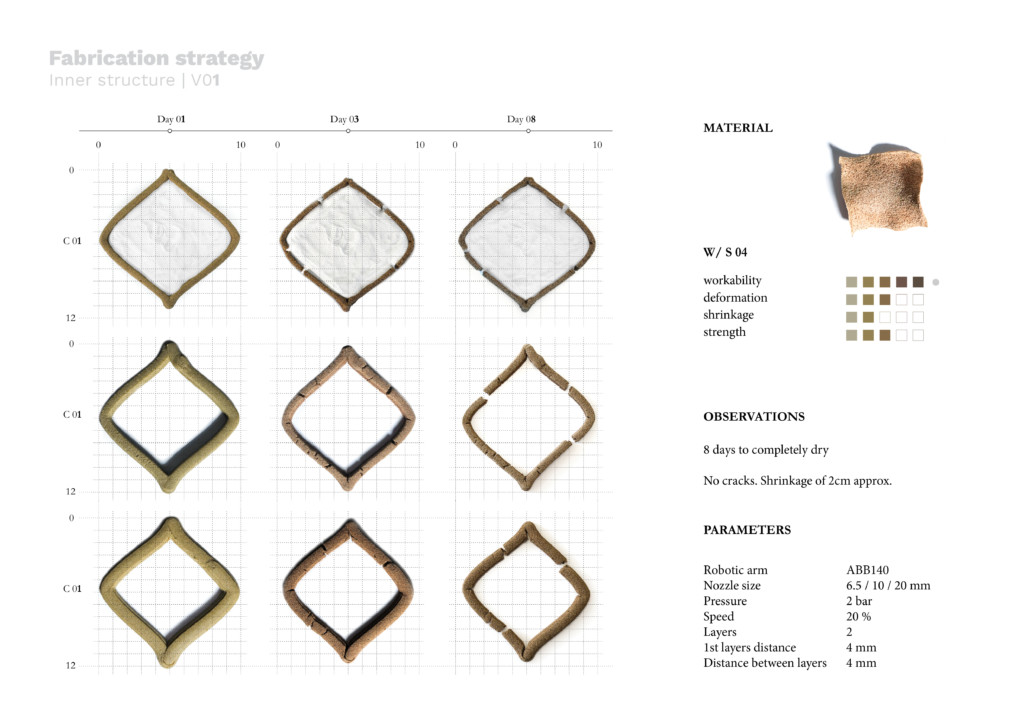

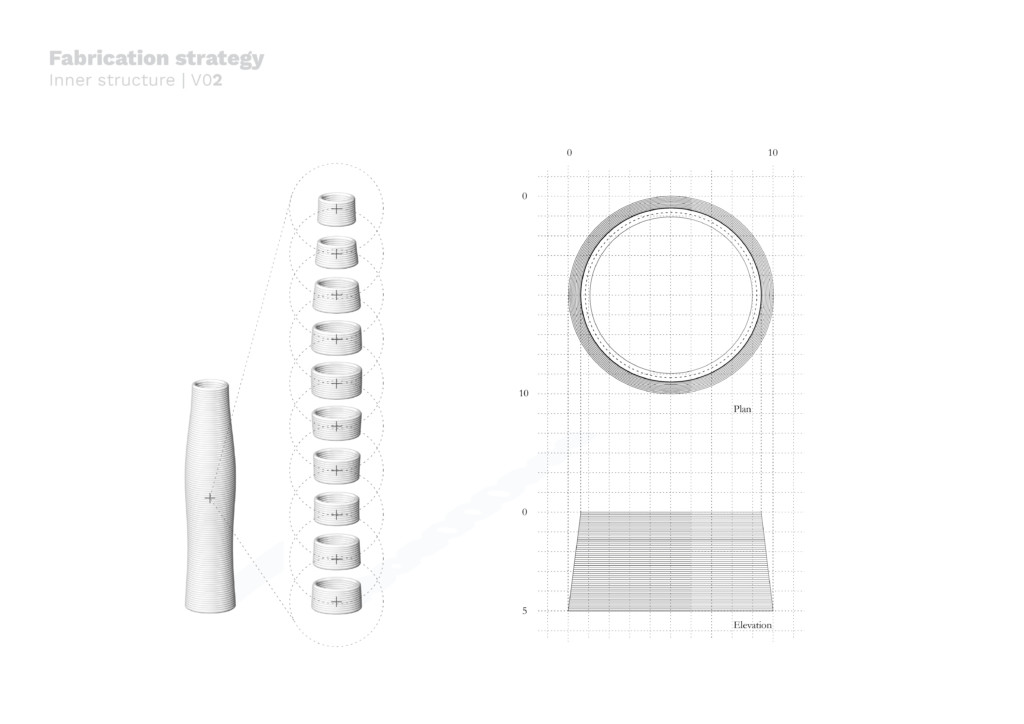

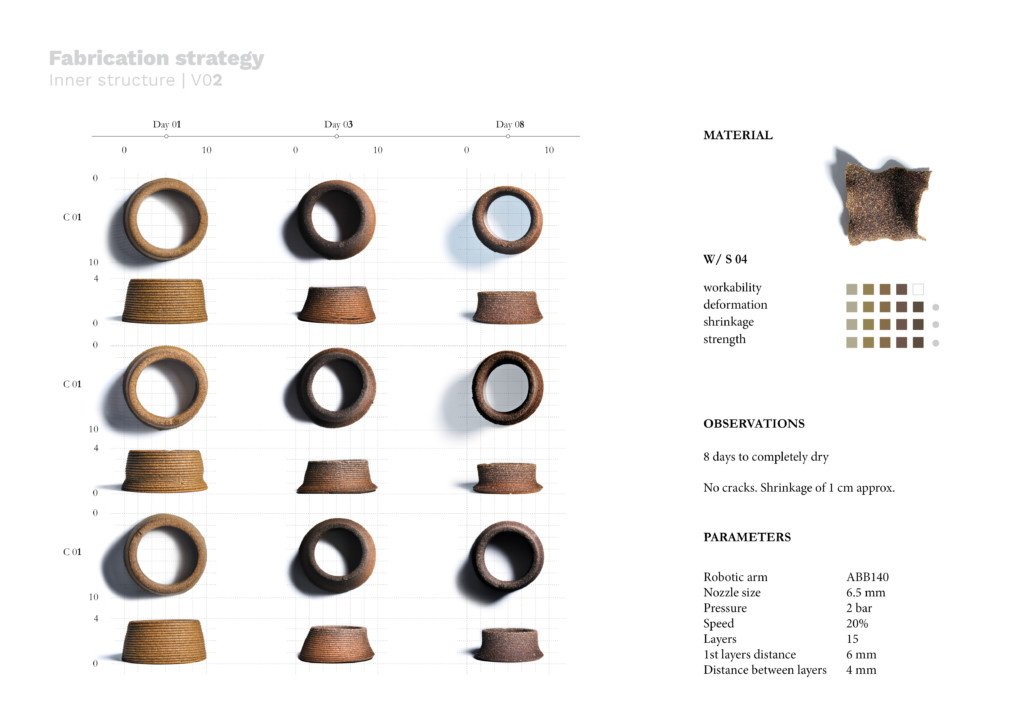

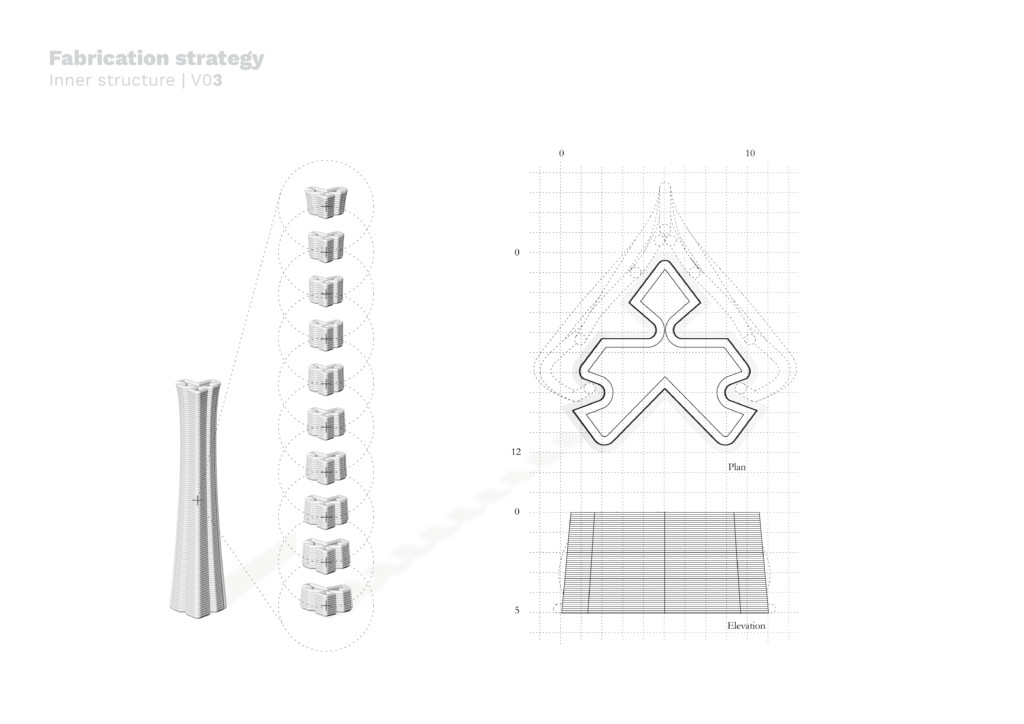

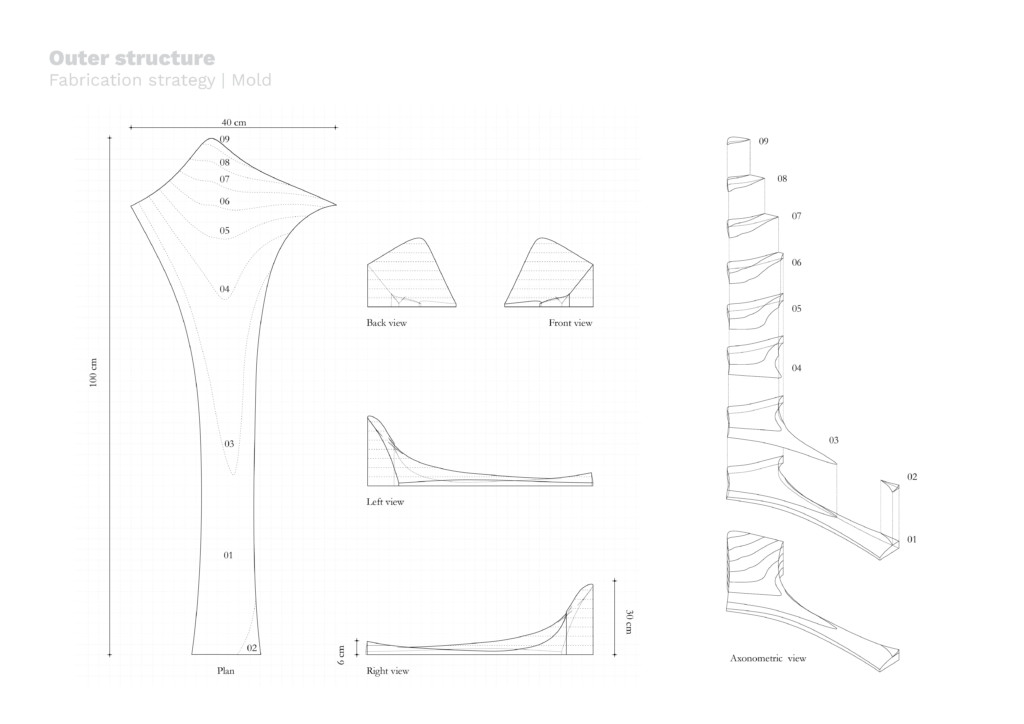

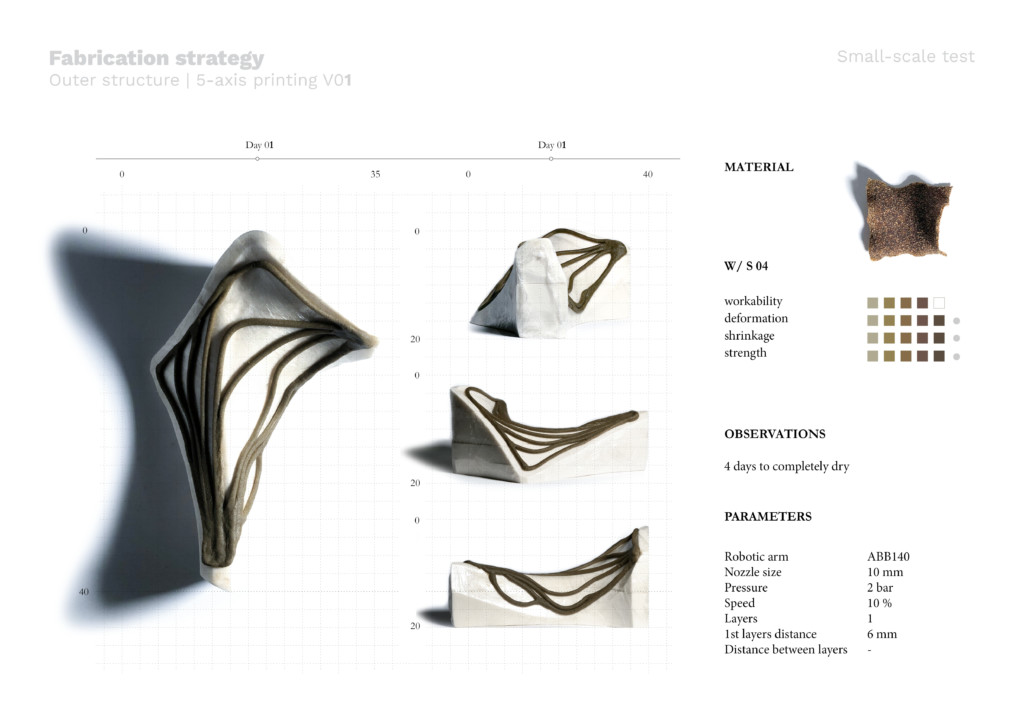

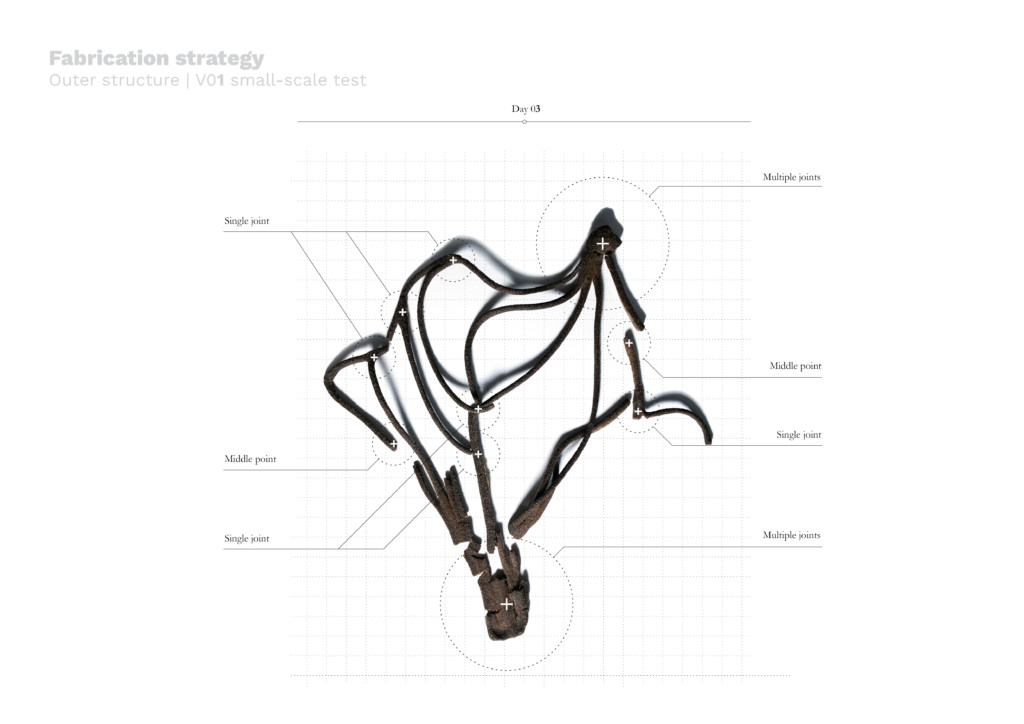

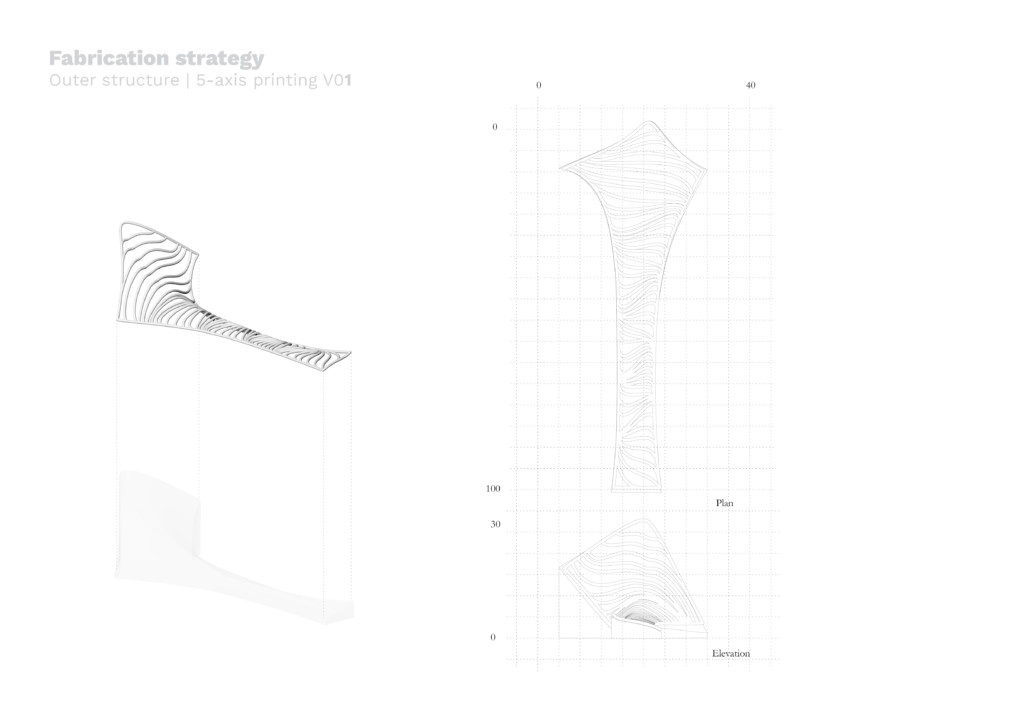

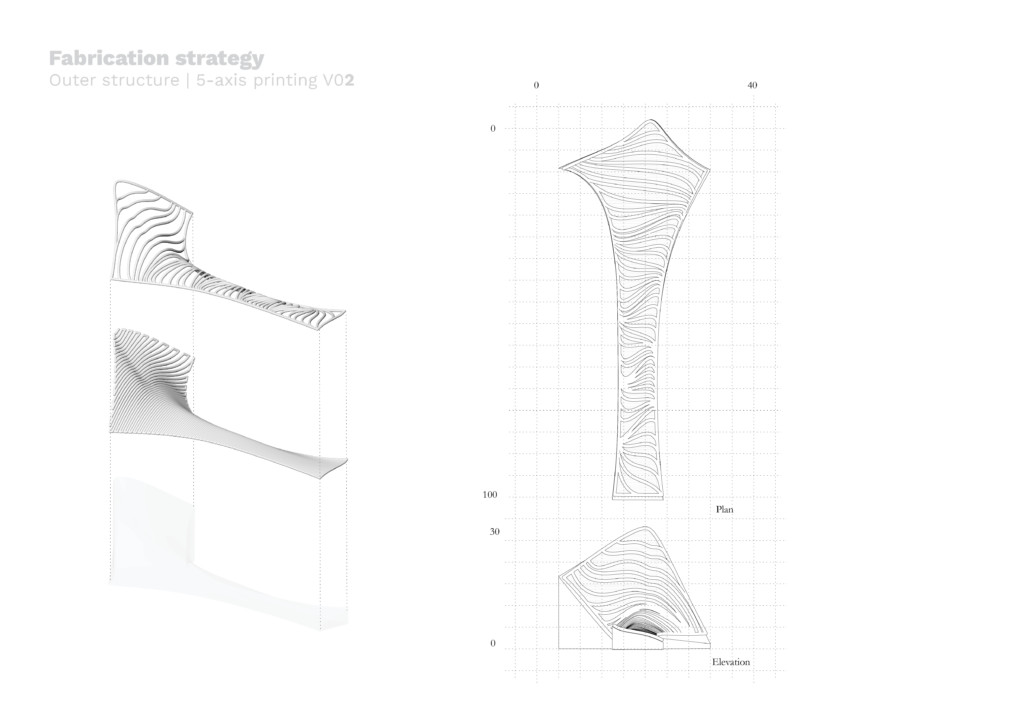

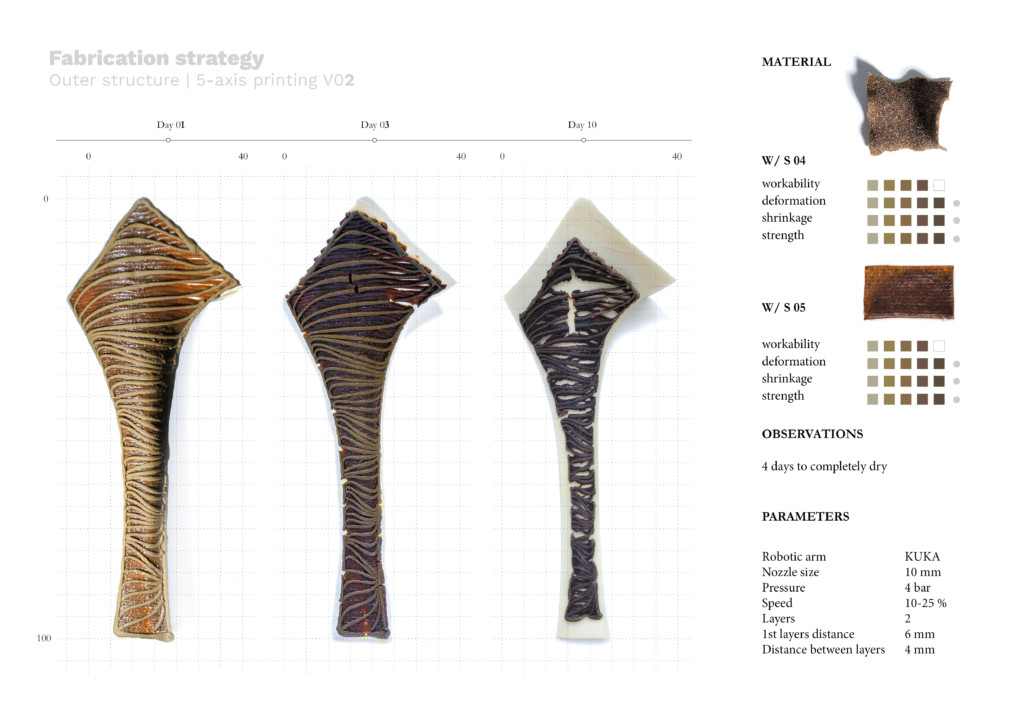

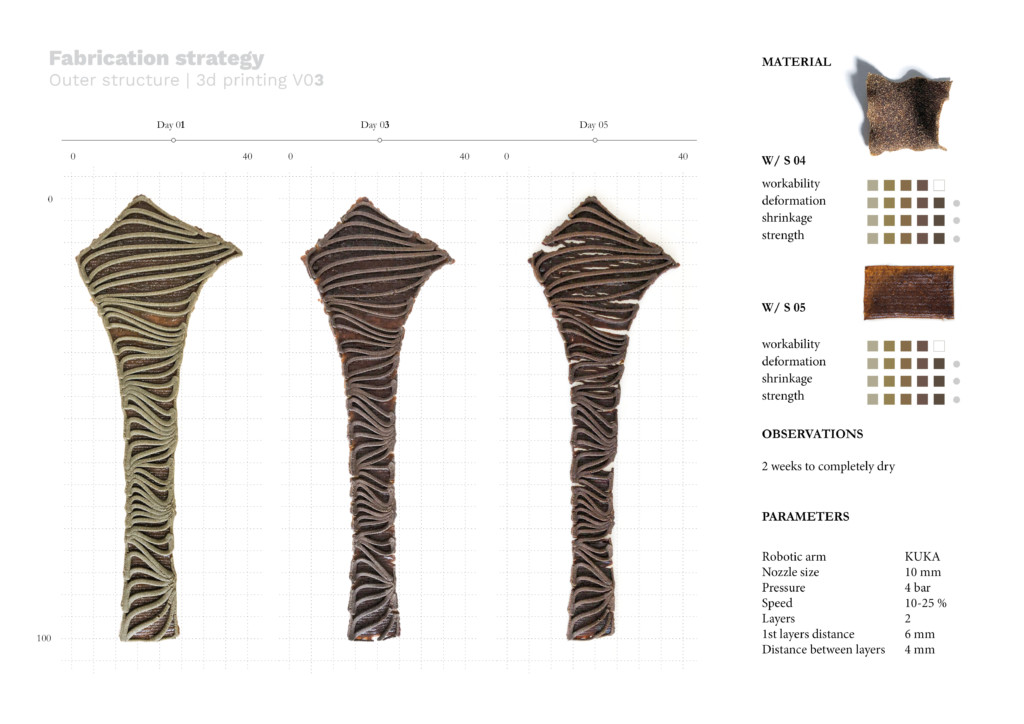

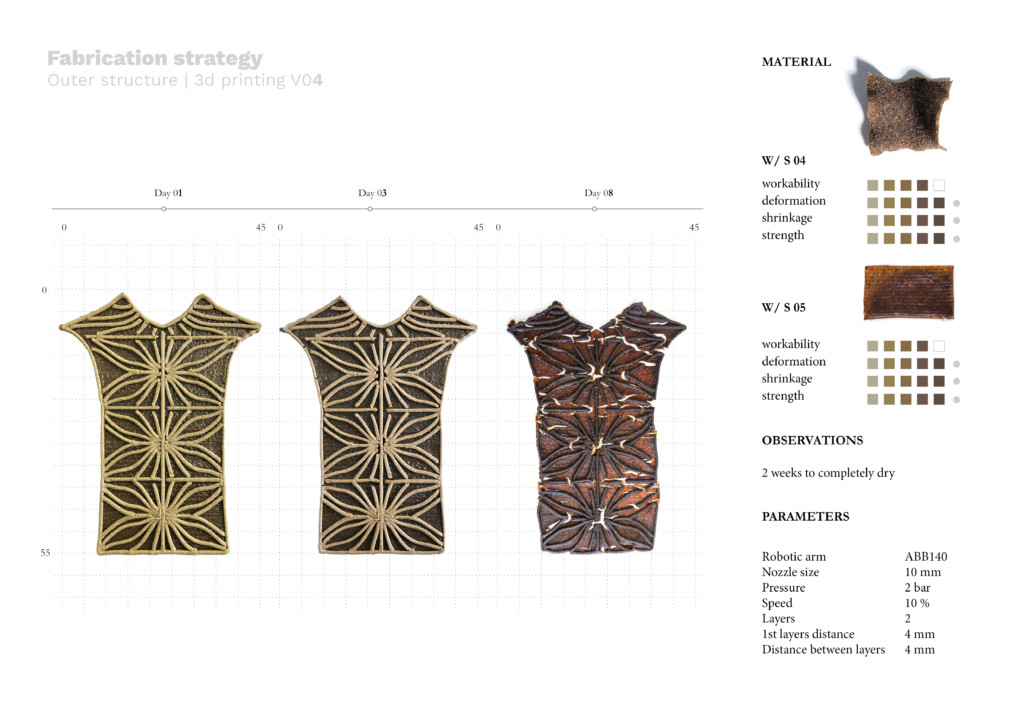

FABRICATION STRATEGY

Pleats of Matter is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at Master in Advanced Architecture in 2021/22 by

Student: Elena Petruzzi

Thesis Advisors: Marcos Cruz & Ricardo Mayor