ABSTRACT

The benefits of having robots could vastly outweigh the problems. (Rodney Brooks 2002)

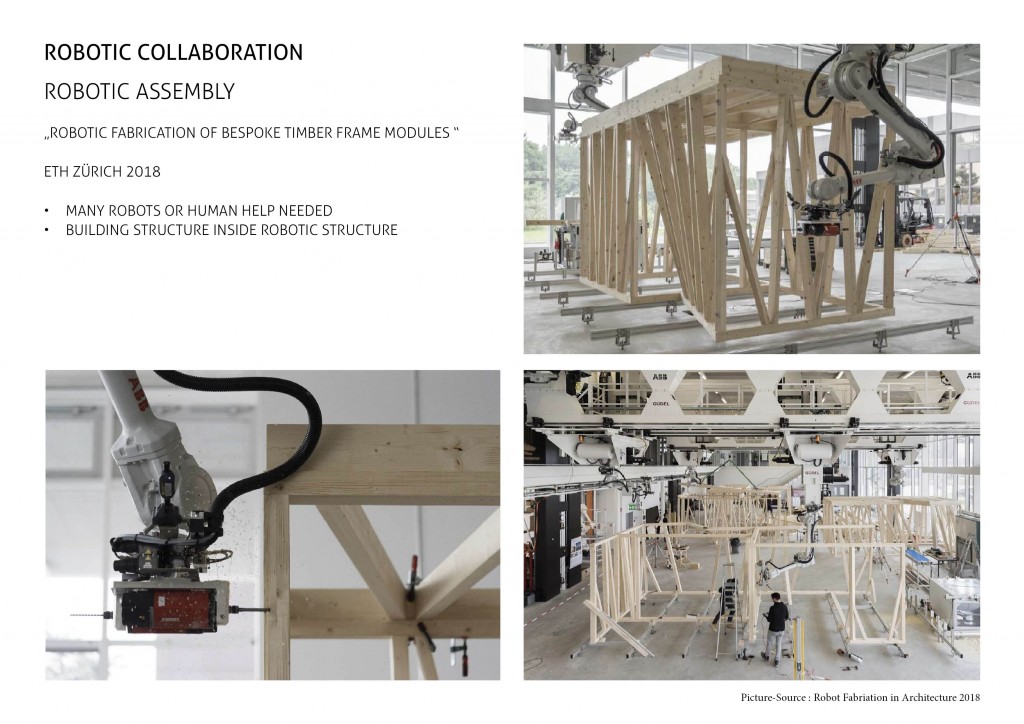

While the synergy between parametric design and robotic fabrication seems to get even closer, the

robotical assembly is mostly impossible without the help of the human touch. That teaches us that

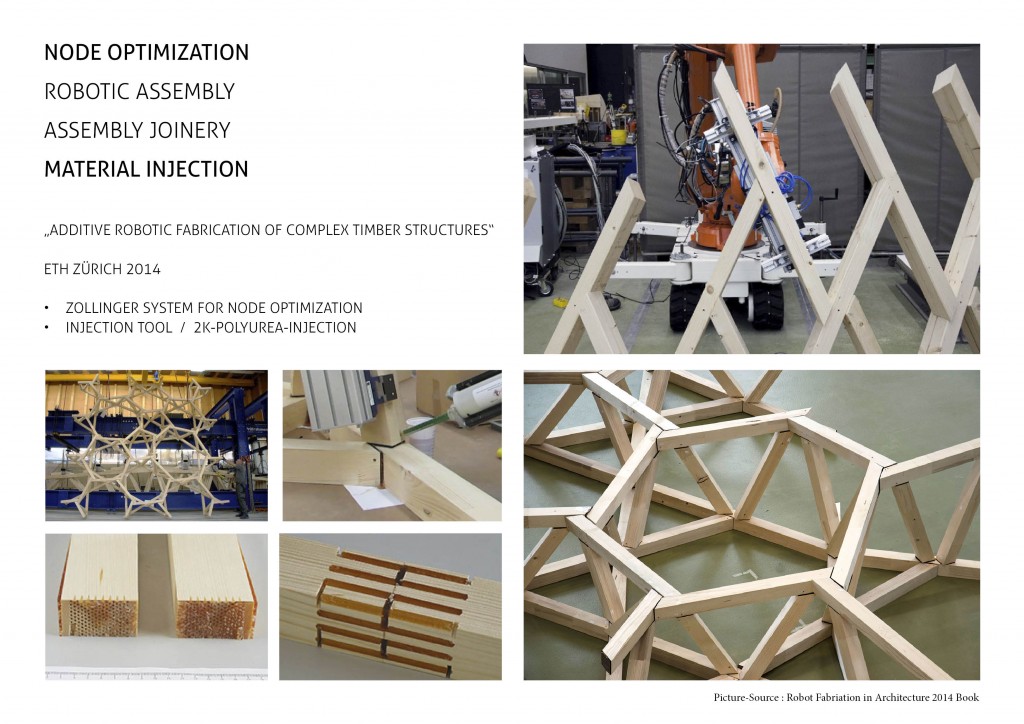

we are still at the beginning of autonomous fabrication. To find the right connection-element to be

assembled by the robot, we have to find solutions, which are time and material-efficient . The con-

necting element has to be also “flexible“ enough to react on different types, needs and dimensions

of different connection-nodes for a complex construction. In the first term, the connection has to

present better solutions in the limitations of the robotic movements and reachability to difficult

assembly-nodes. Finally it can lead to new dimensions of complex structure assembly for big scale

architecture. The connection between elements has to be no longer thougth in terms of human

craft, as in the evolution of robotic craft.

KEYWORDS Autonomous robotics • Assembly • Advanced timber structures • Injected Joinery

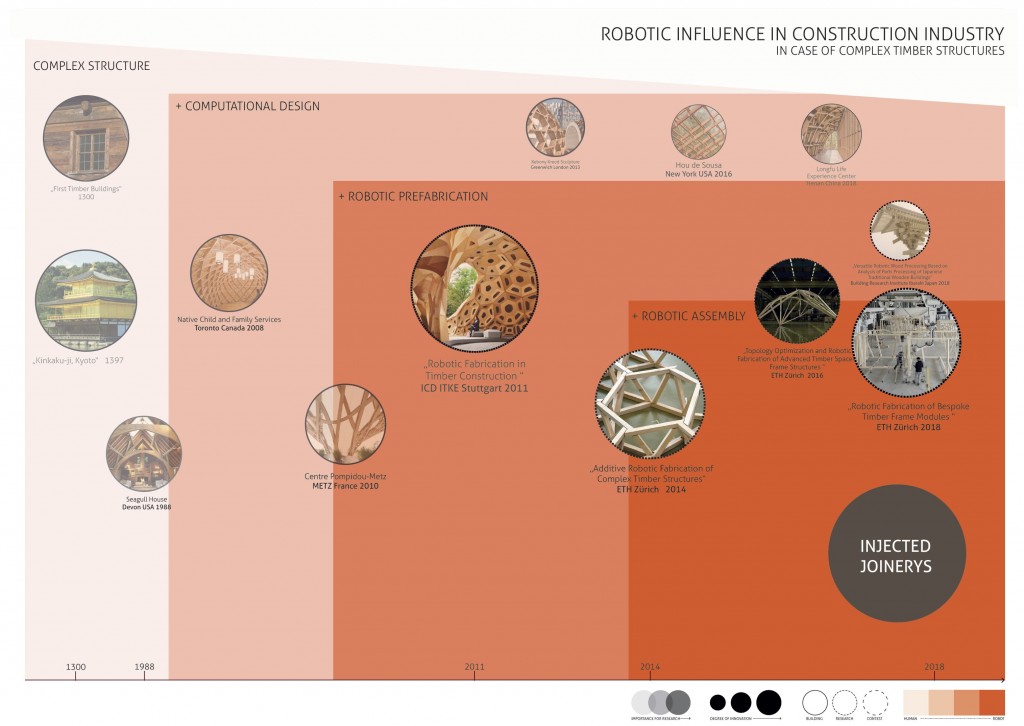

THEORETICAL FRAMEWORK

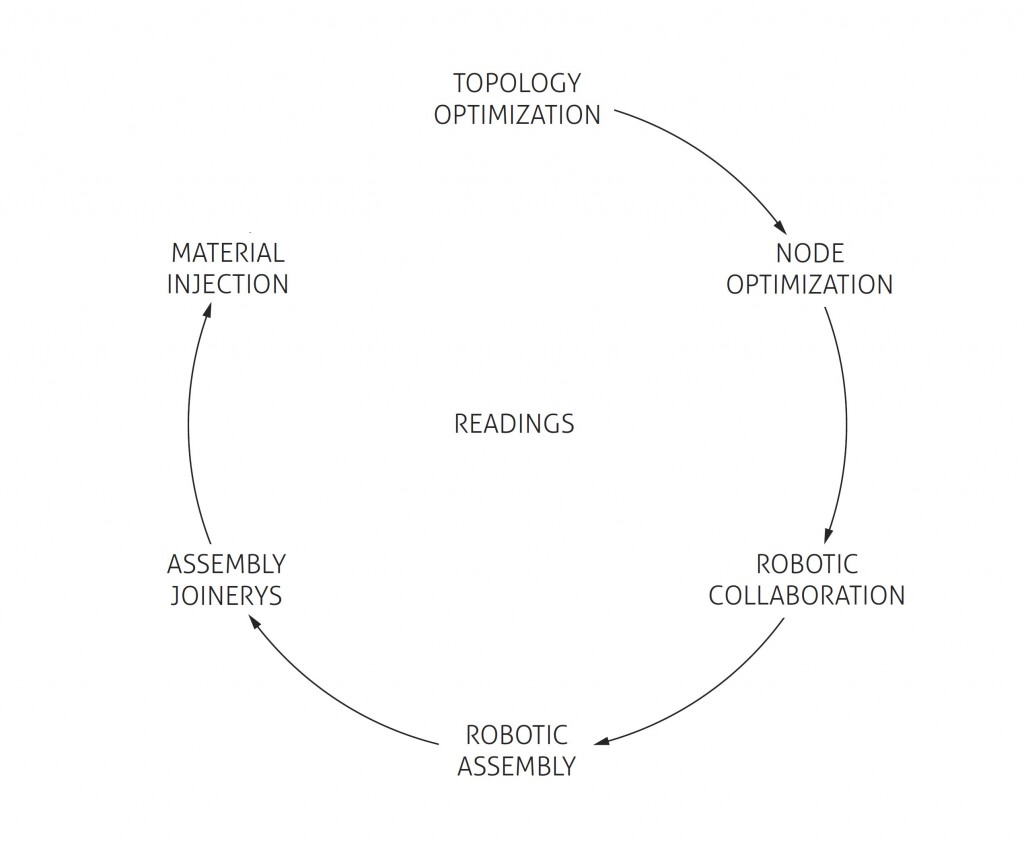

READINGS

For the next steps of my research I have to read a couple of papers handling with all these topics you see in the following diagram. They all affect the sense of Injected joinery as a novel kind of joinerys in construction industry

MOST IMPORTANT PAPER

TO BE CONTINUED …

In the following two terms I get a step deeper to analyze the the different aspects of injected Joinerys as a senseful novel innovation in contruction industry.

Theory & Context is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at Master in Robotics and Advanced Construction (M.R.A.C.) in 2018 by,

Faculty: Ricardo Devesa