Abstract

As hangs the flexible line, so but inverted will stand a ridge arch.

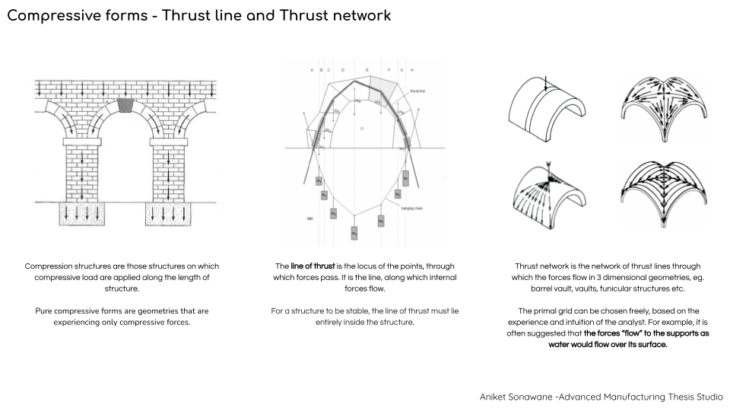

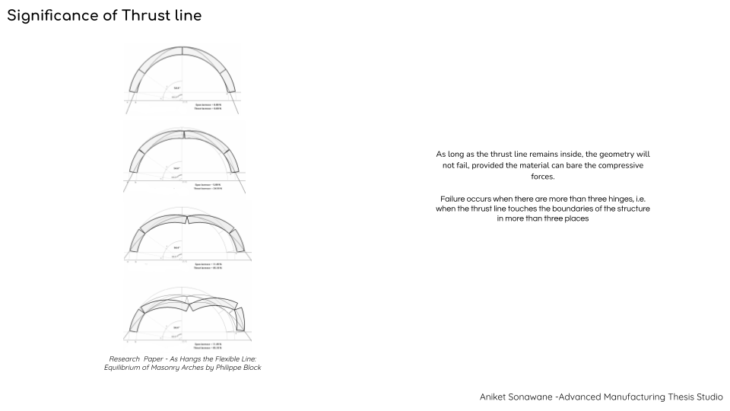

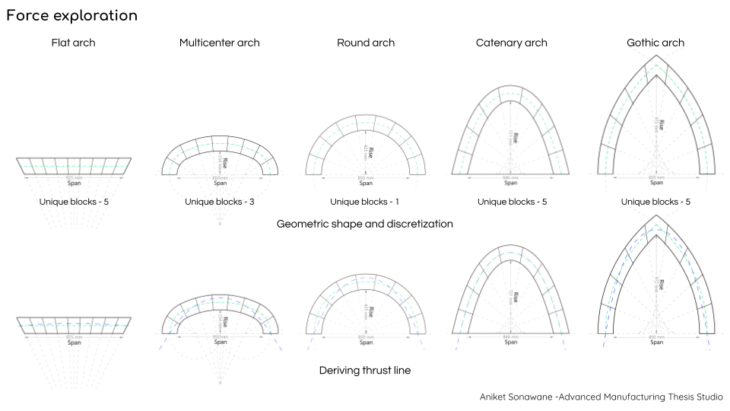

Historically, Arches, domes and vaults have been the backbone of structural technology for constructing buildings. All of these form are compressive forms i.e.. They work best in compression. These forms were explored to maximize their load bearing capacity and were developed from shapes like arches, domes, vaults to pure compressive forms which are funicular structures.

A funicular structure could be said to be a structure which can achieve equilibrium state by adopting a mechanism of a ‘right’ form (shape/geometry) corresponding to the applied loads. This ‘right’ form is referred to as the ‘funicular’ geometry.

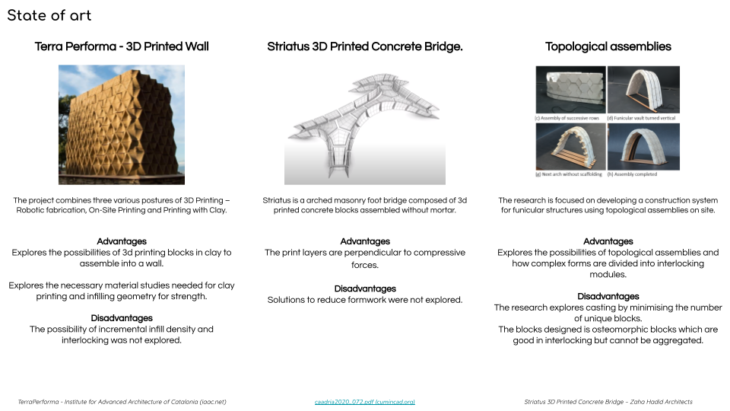

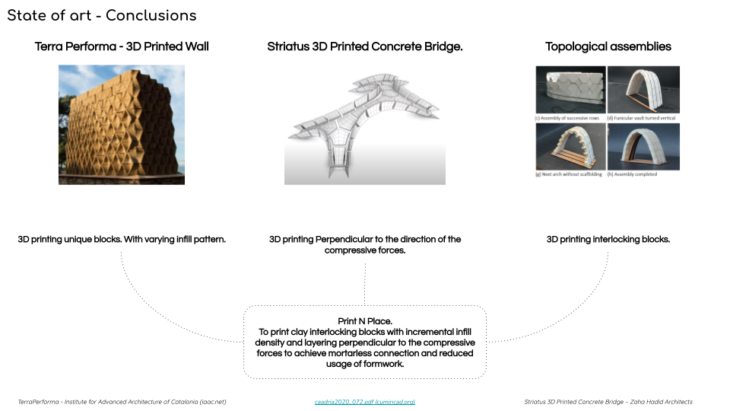

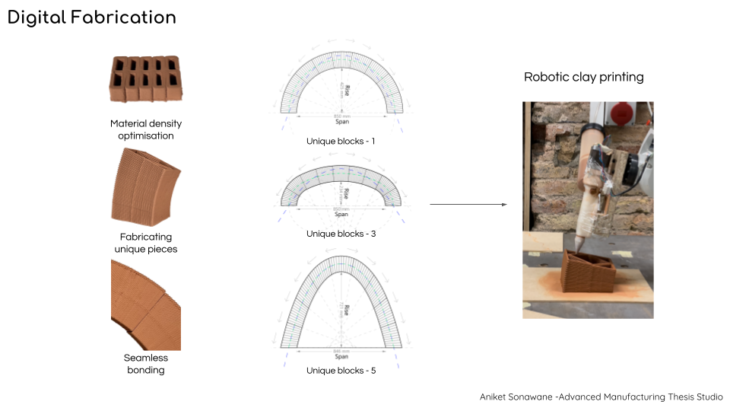

The rise of computer-aided design and modelling techniques and computational tools have language of doubly curved surfaces in architecture, and structural concepts are being integrated as organizing principle of form, material and structure. New digital fabrication methods furthermore made the realization of complex forms technically and economically feasible.

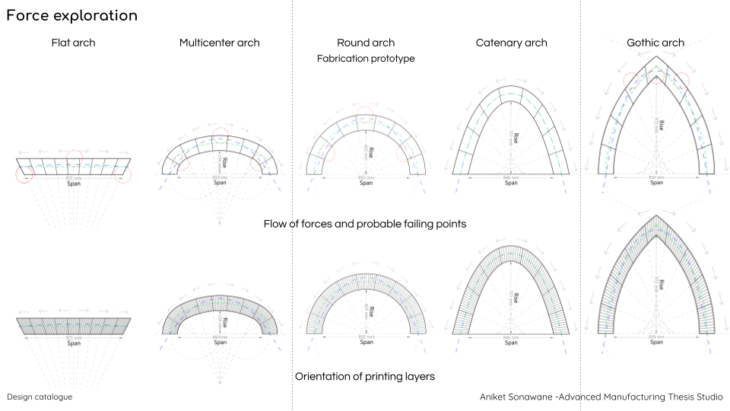

The major drawback for constructing generated funicular structures is that they need precise and unique formwork to build, which is only true to the designed shape.

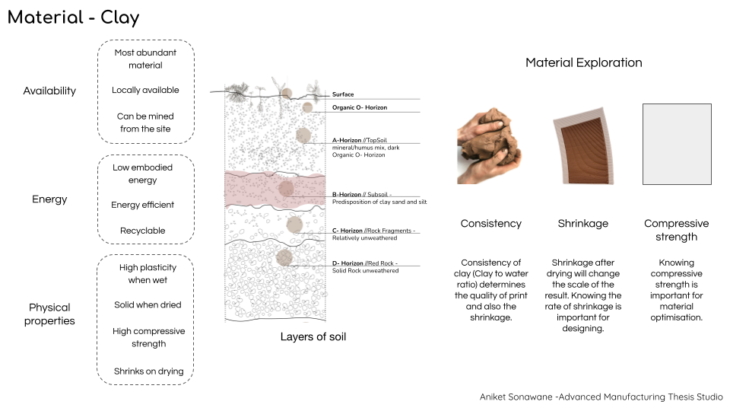

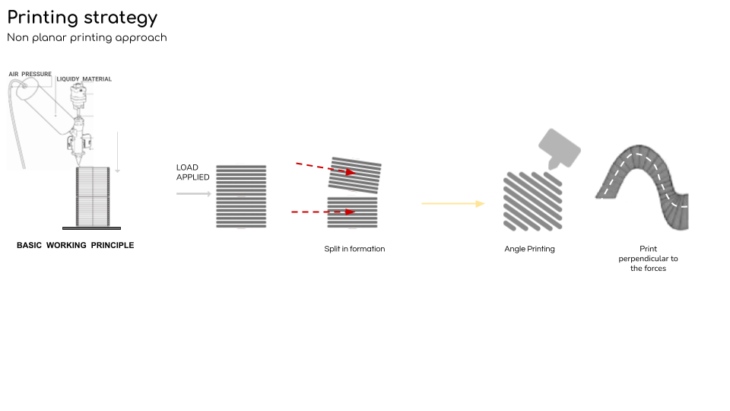

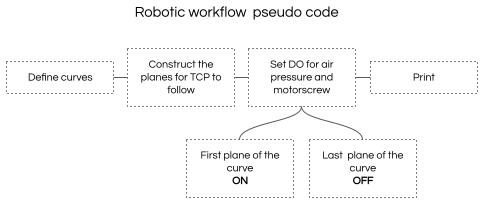

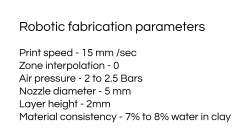

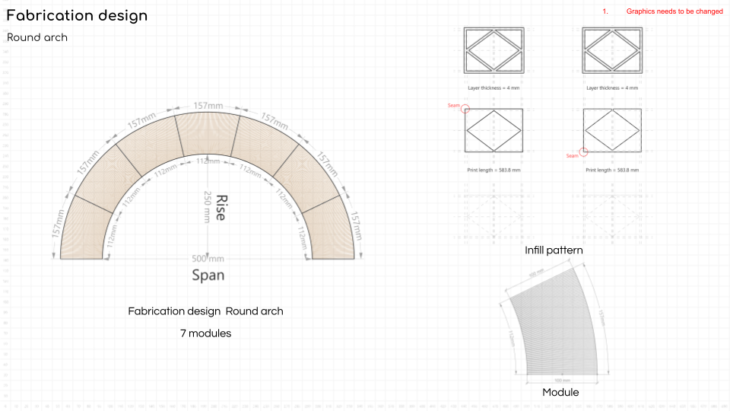

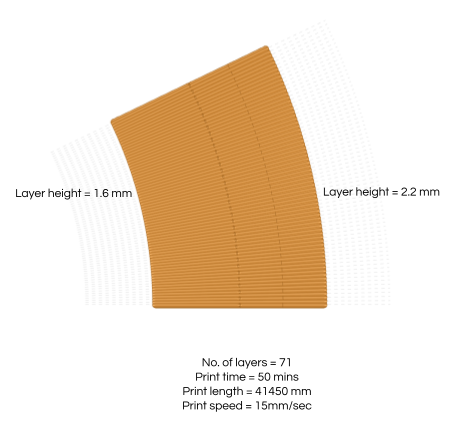

The thesis Printing masonry analyses the forces in pure compressive forms to then discretize it into interlocking blocks, which are then 3d printed using locally available material and assembled using minimum formwork.

The research concentrates on studying the forces experienced by the structure to develop a mortarless construction system for funicular structures using topological assemblies. Topological assemblies interlock with its contact surfaces. Further these force locked elements are kinematically constrained under their own compressive load which helps addition of new blocks without the need of supports, hence minimizing formwork.

Keywords : funicular structures, compressive load analysis, 3d printing masonry, topological assemblies, thrust network analysis.

Humans have always been using compressive forms and as we gained more knowledge we started developing the shape to be more and more efficient.

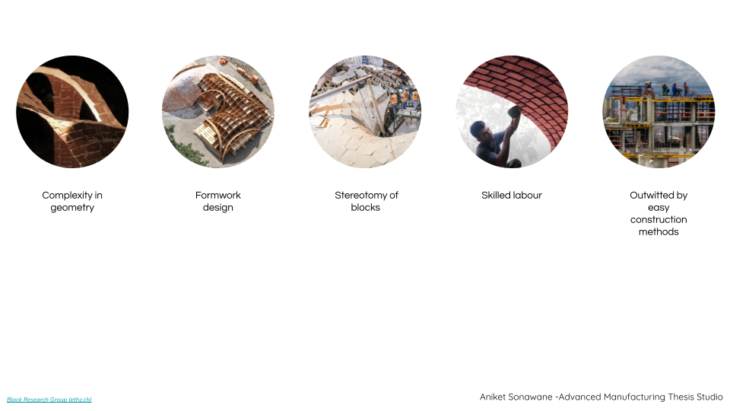

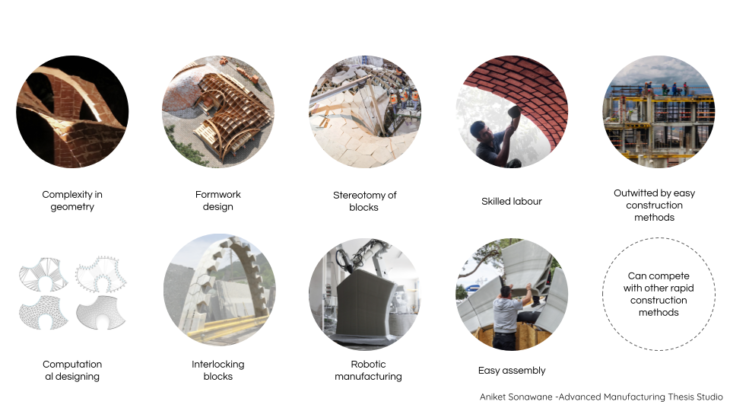

But due to rapid urbanization this construction technology is not able to keep up with the pace due to.

We can try fixing that by applying Computational designing and digital fabrication.