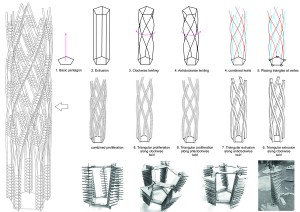

The project initiated with the pentagonal base-sides 30 cm (given). The very idea of understanding the properties of 3 mm thick plywood i.e bending, twisting, stretching etc through the joinery details. The pentagonal base is extruded (given) up-to specific height, which is then twisted in to clockwise and anticlockwise directions in order to determine the bending and twisting properties of wood. The bending curves are extracted from the twisted – extruded pentagon. These curves are further extruded by a triangular geometry to understand the carrying capacity of the base. These extruded triangles are then proliferated by series of planar triangles which act as ties for the extruded curve from the vertices of triangles. The base is proliferated with more triangles allowing stability to the structure. As we go up the density is reduced to provide lighter structure whose only aim is to act as ties.In order to achieve the structure of height 2400 mm the strips are connected by lock and key joints which is clipped by ‘C’ joint in order to restrict the movement. The intersecting strip are connected by sliding joint and clipped in opposite directions controlling the diagonal movement. The base triangles and strips are interconnected via lock and key joint to achieve more stability. Since the direction of each strip is distinctive , 90 unique strips were fabricated and connect through joinery to produce a dynamic structure keeping in mind the material possibility.

The project initiated with the pentagonal base-sides 30 cm (given). The very idea of understanding the properties of 3 mm thick plywood i.e bending, twisting, stretching etc through the joinery details. The pentagonal base is extruded (given) up-to specific height, which is then twisted in to clockwise and anticlockwise directions in order to determine the bending and twisting properties of wood. The bending curves are extracted from the twisted – extruded pentagon. These curves are further extruded by a triangular geometry to understand the carrying capacity of the base. These extruded triangles are then proliferated by series of planar triangles which act as ties for the extruded curve from the vertices of triangles. The base is proliferated with more triangles allowing stability to the structure. As we go up the density is reduced to provide lighter structure whose only aim is to act as ties.In order to achieve the structure of height 2400 mm the strips are connected by lock and key joints which is clipped by ‘C’ joint in order to restrict the movement. The intersecting strip are connected by sliding joint and clipped in opposite directions controlling the diagonal movement. The base triangles and strips are interconnected via lock and key joint to achieve more stability. Since the direction of each strip is distinctive , 90 unique strips were fabricated and connect through joinery to produce a dynamic structure keeping in mind the material possibility.