IAAC – Master in Robotics and Advanced Construction

Studio I

Faculty: Alexandre Dubor, Raimund Krenmueller

Faculty Assistant: Roberto Vargas

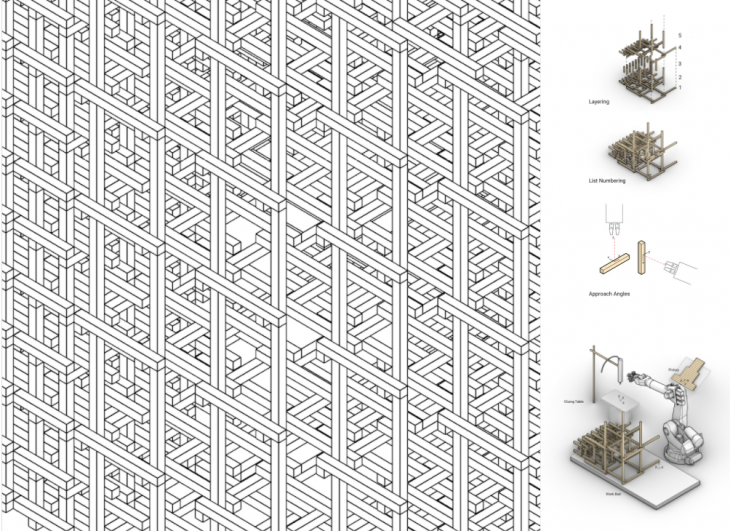

ROBOTIC CRAFT: DIGITAL AGGREGATIONS

Credits: IAAC Student Project “FrameWork”

Syllabus

The current trend of Industry 4.0 promises groundbreaking technologies such as robotics, accurate sensing, computational design, AI and cyber-physical systems that can potentially transform the way we design, build and inhabit, tomorrow. How will we integrate these new technologies into the creative development of design and architecture? What are the new material tectonics revealed by robotic technologies? How can we use digital design tools to customize our production and achieve tailored performance ? The studio “Robotic Craft” proposes to guide students through the exploration of robotic fabrication technology for architecture, via a series of guided exercises that involve manual craft experiments, digital design, hands-on prototyping, robotic experiments, detail design and architectural applications. This year’s approach to this exploration will be to start with the question of aggregation, or how to combine small parts into coherent architectural elements, a question treated by architects and constructor for millenia, but can be revisited today with the precision and mass customisation potential of digital technologies.

A particular attention will be given in the studio to analyse the new possibilities offered by flexible robotic processes to negotiate more complex parts variation, allowing from one hand to accept recycled parts with varying shapes, and allowing on the other hand to customize each part and each composition to the specific requirements of each building, each function, each climate, each culture…to architecture.

Learning objectives

At course completion the student will:

- Have a general understanding of digital fabrication principles and concepts applied to architecture and construction,

- Be able to tackle a multi-aspect, multi-scalar architectural design and fabrication task using computational design and robotic fabrication tools,

- Have a deeper understanding of an integrated digital design and fabrication process,

- Be able to relate material properties to manufacturing parameters and control a robotic fabrication process accordingly,

- Be able to create robot programs, simple custom end-effectors and material handling tools to manipulate sheet materials using the 6-Axis robots at iaac.