Simple to Complex

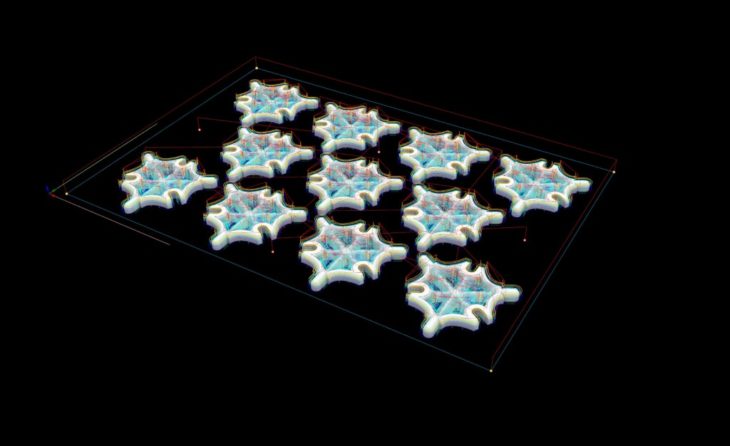

INNER COMPLEXITY is a digital fabrication exercise exploring the extent of fabrication possibilities of the CNC process. Special care was taken to work intelligently within the limitations of the process as well. In order to achieve a recursive geometry a simple hexagonal repetition was explored. Material was then removed from the base hexagonal geometry in order to lighten its structure, increase the topological complexity of each module, and extend the recursive possibilities of the form.

Combining CNC Processes

Using a 2-axis profiling technique allowed for tight joints to be achieved. A 3-axis finishing process of rounding the male joints allowed for a wider range of motion of each joint. A lighter module was achieved by a 3-axis material subtraction within each hexagonal panel. The removal of material was based on an algorithmic sculpting of the surface. This left behind a more intricate layered surface highlighted by the exposed layers of plywood.

Geometric Possibilities

By the nature of the directionality of the joints, the geometry naturally curves in on itself. This creates an “inner complexity” within the curved surfaces as the modules are repeated. More rigid or more organic forms can be achieved based on the flexibility of the joints.

INNER COMPLEXITY is a project of IAAC, the Institute for Advanced Architecture of Catalonia, developed in the Master in Advanced Architecture (MAA01) 2021/22 by students: Michael Groth, Perniyal Waseem, Stanislas Naudeau, Vaibhav Toshniwal; faculty: Shyam Zonca, Lana Awad, Marielena Papandreou & Ricardo Mayor; faculty assistant: Karthy Vijaya & Ilaena Napier