General Explanation

Following the subject of the seminar, we had to develop an actuator to be mounted on a robotic arm and be able to perform a task. In this manner we explored the possibilities of sewing various materials, with a general goal to achieve a connection between rigid materials, using a portable, cheap sewing machine that we modify.

Concept

According to the traditional techniques for sewing, the machine is stable and the material is moving. In our case the process is inverted, as the machine is moving freely by the robotic arm and the material is held by a support structure.

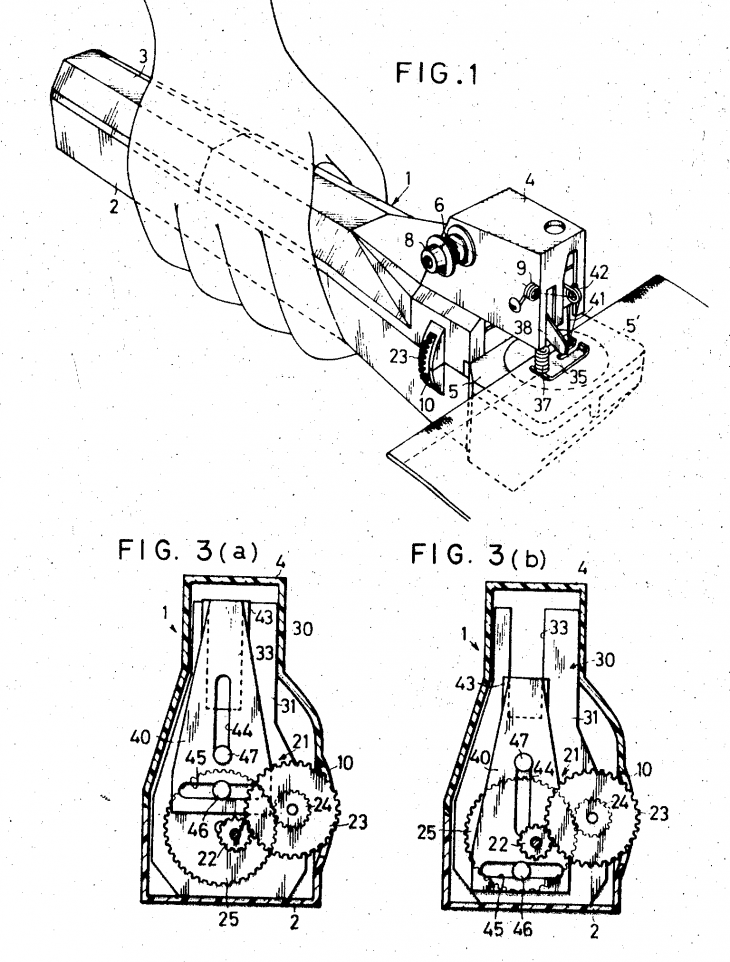

Portable electric sewing machine |

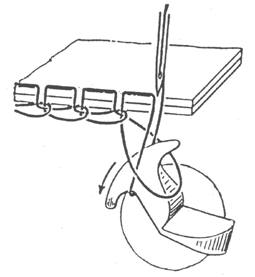

Gibbs’ rotating hook chain stitch mechanism |

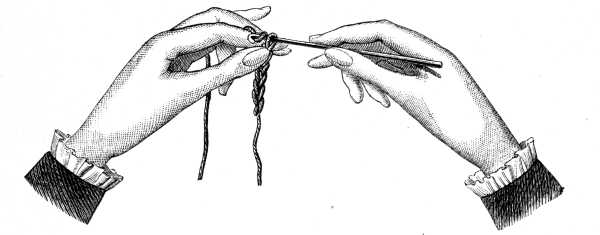

Position of the hands and explanation of chain stitch |

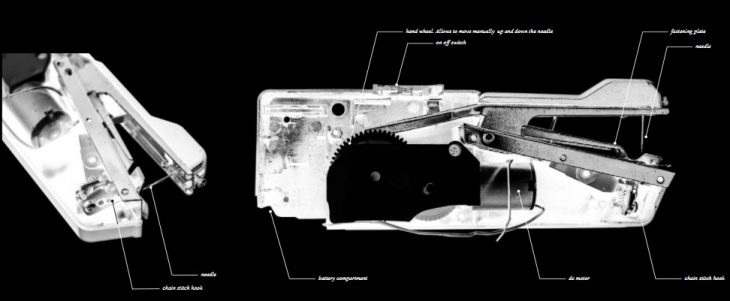

Portable Sewing Machine

The biggest challenge in the project was to transform this portable sewing machine that looks more like a toy, into a tool that can allow us new possibilities in the sewing process. On the technical part, the machine is using a hook to perform a chain stitch with one thread and is powered by four 1.5V batteries.

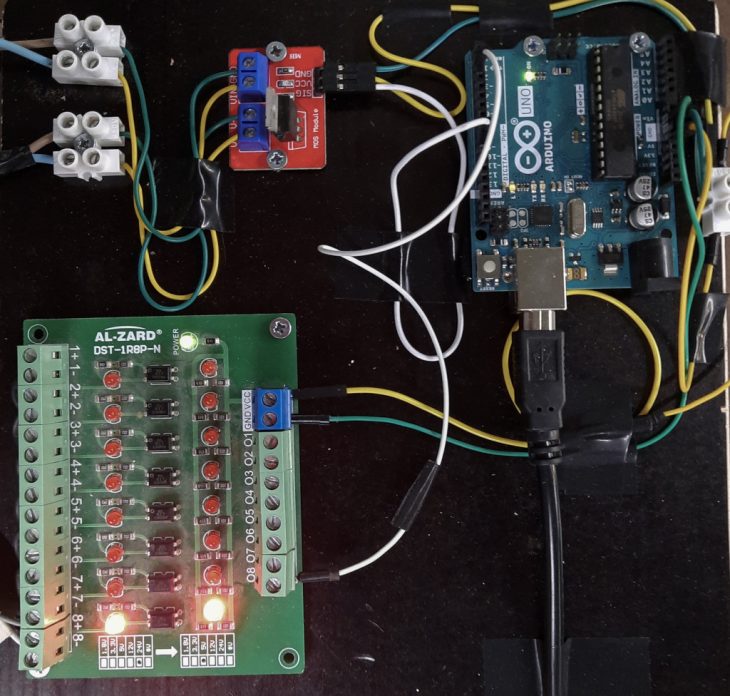

Schematic and Wire prototype

During the manual tests with the machine in the original state, we defined the parts that need to be

modified. Since the machine will be controlled by the arduino we changed the on/off button with

a digital signal from the arduino.

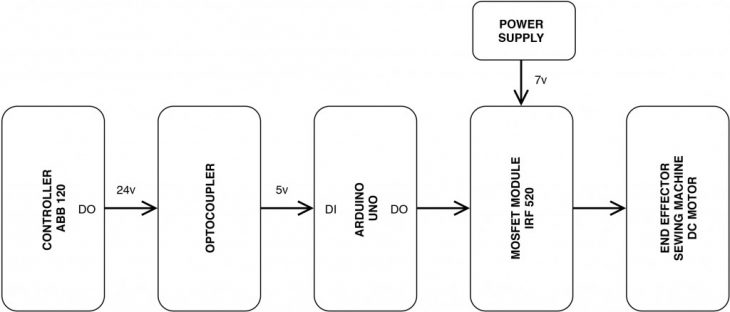

Wire Prototype Flow Chart Schematics

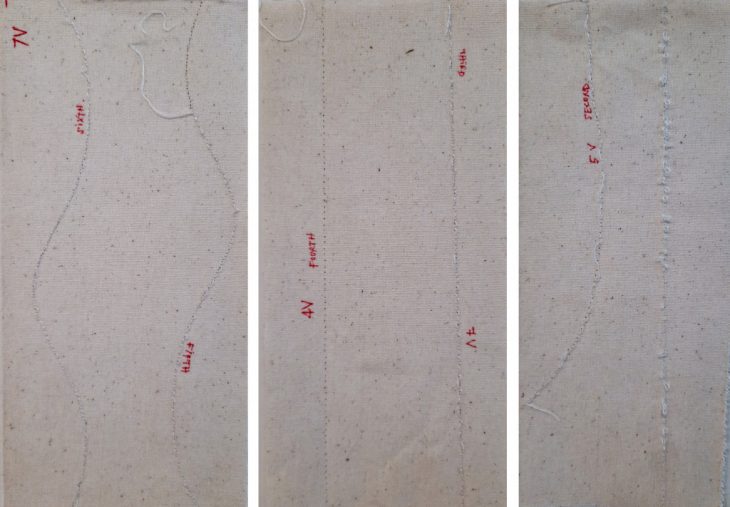

Then we added different speed options, but after testing more rigid material it was clear that the power that the machine was getting from the batteries in not enough. Therefor the biggest change is replacing the batteries with a power supply and experimenting with different Voltage according to the material and the speed of the robot.

Differents test of Voltage related to differentes materials. In this case an specific fabric. The voltage selected was 7v .

Previous Test

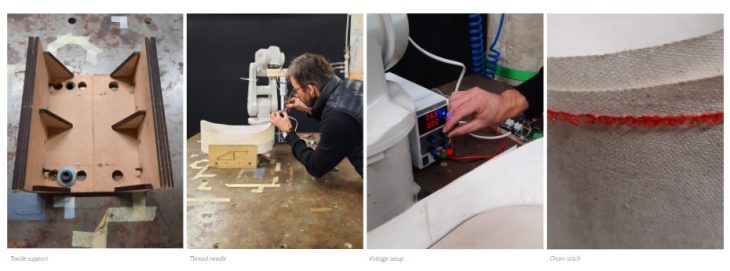

In the first test of the machine mounted on the robot, a simple linear path and a “paper like” material were used.

Robot Path Simulation

Moving to a more complex robot path, we understood the importance of moving the machine according to the curvature of the stitch and not vertical to the ground.

Final test Setup

During the final tests, we achieved a stitch of a closed curve and also experimented with more rigid materials, like plastic and balsa wood proving that by modifying this portable sewing machine and mounting it on the robot, we can achieve accurate connections between curved surfaces of different materials.

Robotic Actuators | Sewing Robot // Hardware I is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at the Master in Robotics and Advanced Construction in 2020/2021 by:

Students: Alberto Browne, Juan E. Ojeda, Orestis Pavlidis

Faculty: Angel Muñoz

Faculty Assistant: Matt Gordon