Workshop Brief

This workshop was an exploration in the relationship between real-time robotics, augmented reality, material behavior and self-organising generative models.

Team Responsibilities

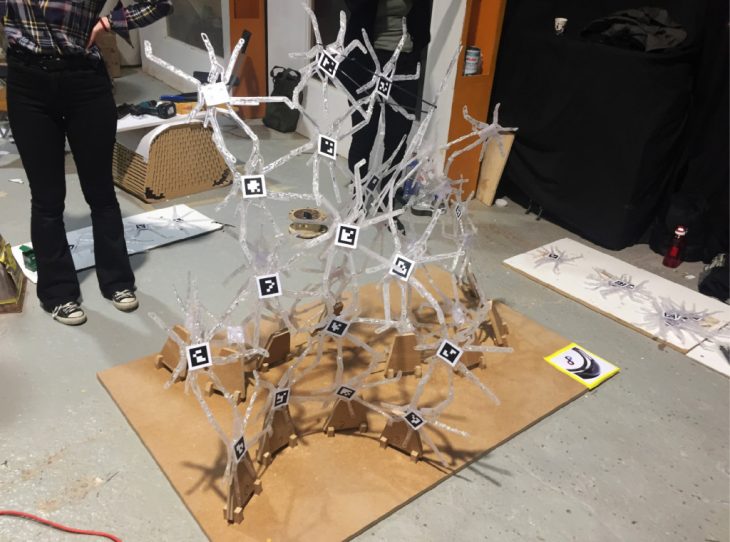

The first task assigned to the assembly team was to come up with a technique to attach the AR markers to each of the components in a similar fashion. So that each component can be referenced in the 3D model in the correct position and orientation as the actual structure in the physical world using the HoloLens.

The next task then was coming up with a methodology of attaching the different components together to form up the overall final structure.

The assembly process was done using HoloLense that provided a realtime reference of the exact position of each components informing the whole assembly process.

Challenge

The biggest challenged faced until Wednesday was to understand how to match the printed pieces of the structure with the digital model, through AR Markers.

Solution

To solve the problem we have been through many possible solutions, indeed AR Markers where able to give us (through Computer Vision) a center and a coordinates system specific for every marker, understood that it was just a matter of linear algebra transformation matrices to move the physical coordinates system placed on the marker and match it with the digital piece of the structure visible through the HoloLens.

The biggest problem was how to achieve the best and most precise result with only one single marker every piece. To do so, we knew that every 3D printed piece had a core which was the same for every component. Knowing this we decided to take a reference point on the core and glue the markers on the same exact position every time, this way allowed us to to match the physical with the digital in a precise and fast enough way.

Once we fixed the “physical” problem of where to attach the AR Markers, we had to find the transformation matrix that could give us the exact position of the physical piece in the digital environment. Through a very simple grasshopper script we managed to get the transformation matrix between the coordinates system of the physical base, which was also the coordinates system of the digital base, and the position of the printed element.

This way we had a safe way to mount the structure

Future Steps

A better and safe way to solve to problem to bridge the physical and the digital, through AR Markers, would have been to proceed and place 3 Markers on every single piece, in this way it wouldn’t have mattered the actual position or orientation of it on the printed element, because we could have got rid of the (inaccurate) coordinates system given by one single AR Marker and took the safe plane that goes through the 3 centres on the Markers.