DISCRETIZING ROBOTIC PROCESSES

WORKSHOP CONTEXT: Machines and robots are programmed with zero tolerance. However, in the physical world, there are always inaccuracies that are very hard or even impossible to predict, such as the bending of wood as an anisotropic material. This makes it difficult to program complex robotic processes in advance and leads to bloated code that tries to cover every potential outcome.

ROBOTIC TACTILE SCANNING

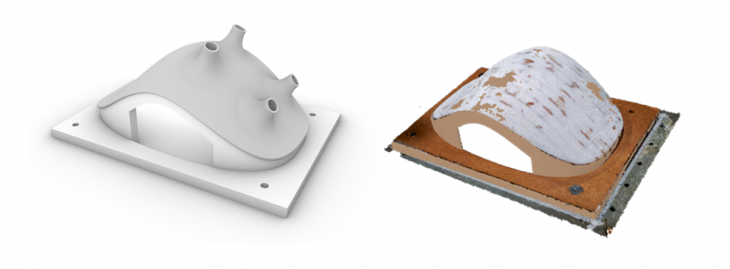

PROJECT CONTEXT : This project was an alternative to scanning techniques involving cameras (photogrammetry), or RGBD cameras. We fabricated a mold which was milled from a flat sheet of MDF for printing a chair onto as seen the images below. However, when the individual components were assembled and we tried printing on top of it, we found some inaccuracies between the digital model and the physical prototype. Thus a feedback in necessary in order to use the mold for robotic 3d-printing.

INSPIRATION : A carpenter or artisan uses his/her hands to feel the materiality and unevenness of the surface. This human touch is essential for actions like sanding, polishing etc. However, such low-level feedback is missing from the robotic processes. We hypothesized that we could use the torque sensors on the Kuka iiwa robot to have this tactile feedback.

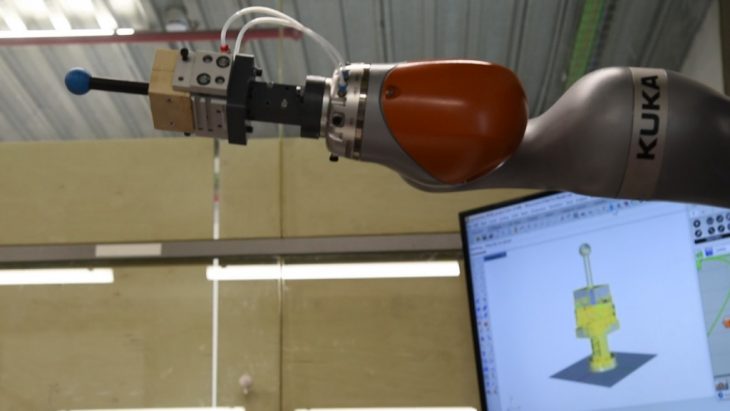

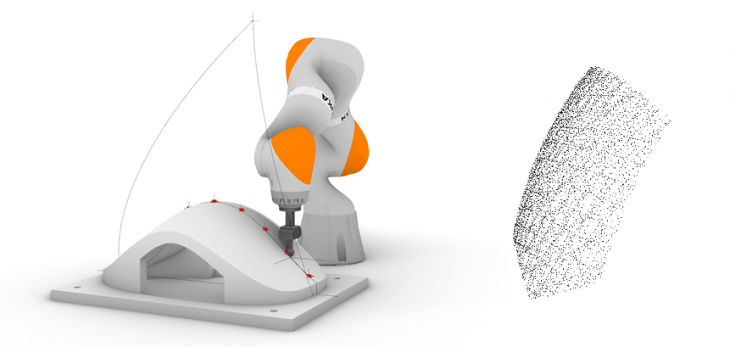

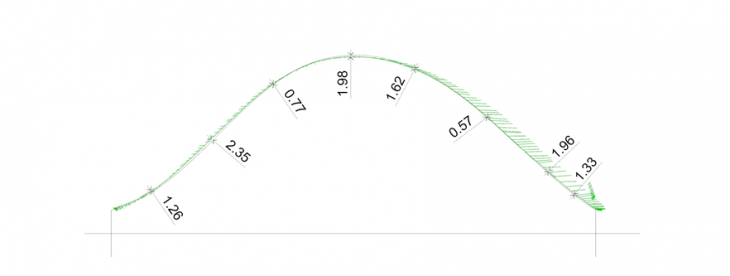

TOOLPATH : We made a toolpath as shown in the following image for the robot to run the path defined and record the positions.

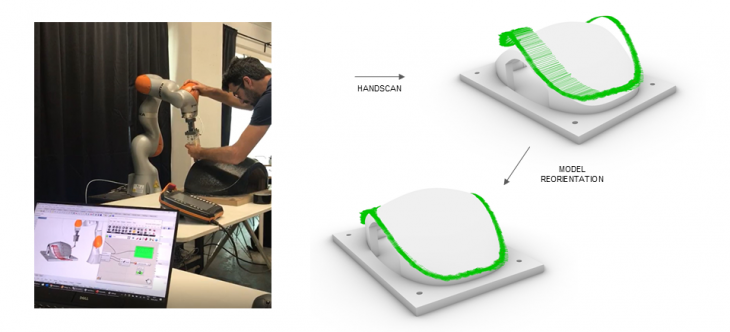

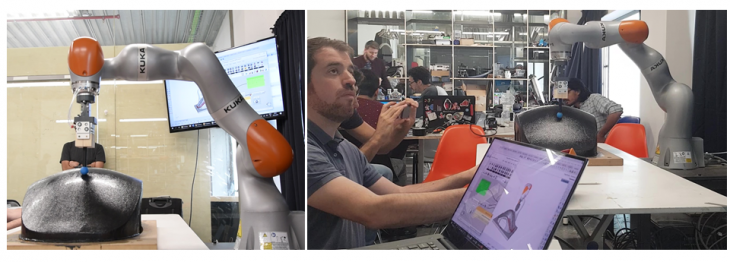

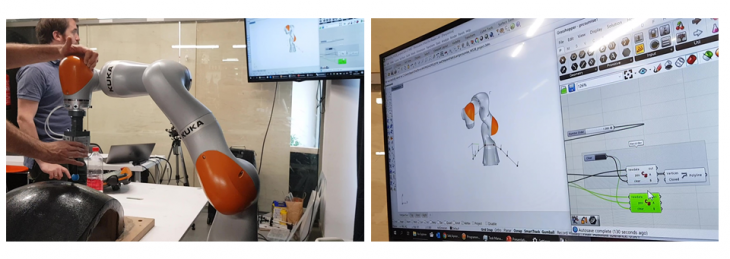

HAND-GUIDED CALIBRATION : To align the physical model with the digital its sure easier to measure at least 3 of the edges of the rectangular base-shape but having the opportunity for using an Kuka iiwa robot, we liked the idea of sensing the outline of the double-curved shape of our mold with the hand-guiding program of the iiwa.

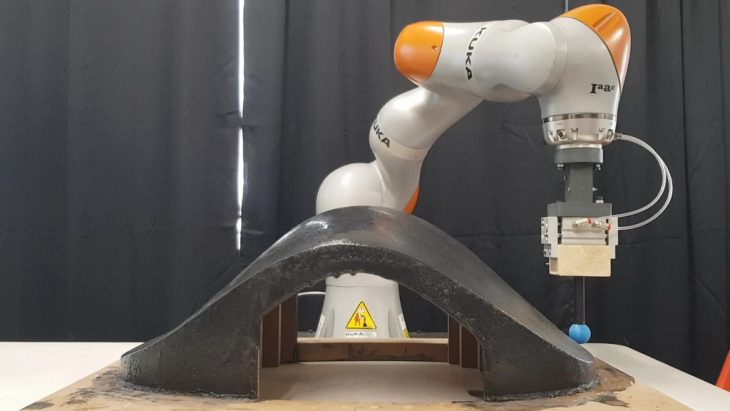

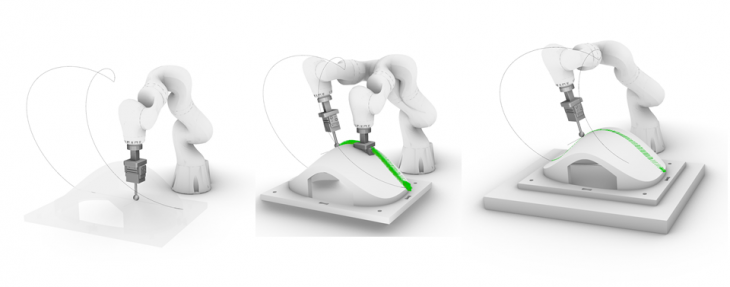

TEST 1: PRE-DESCRIBED TOOLPATH : We send a pre-defined toolpath of the shape center curve to the robot and soften the stiffness and the safety threshold of the robot to run the path on the shape to record the real positions of the robot to adjust the digital model according to the measurements.

TEST 2: STRAIGHT LINE AS A TOOLPATH : By figuring out that the result of moving over the mold, with the predefined curve, worked very well we wanted to push the possibilities of the iiwa robot to its limits. Hence, we send a linear movement of just 2 points through the mold geometry by considering that this will affect a collision in every other machine which could damage the machine or/and the mold. In the case of the kuka iiwa we decreased the stiffness and safety threshold quite before the robot relaxes to much to collapse by gravity. The robot was nicely moving over the mold and we received the recorded way points via grasshopper.

TEST 3: HAND GUIDANCE POSITIONS : Finally we also wanted to give the pre-programmed hand-guiding program of the kuka software a try .

CONCLUSIONS : In the project we also tried to align the robot, while scanning the shape, according to the shape-normals by receiving the forces and the direction of the forces . But there where a couple of theoretical problems like the buffer between receiving the forces and realigning while moving on the surface and also detected forces which where not useful for a normal realignment.

But in case of tactile scanning we received promising results, which we gave much trust because we received always the actual position of the Robot-TCP calculated over the 7 joint-positions of the robot. And they are quite accurate as we imagine.

And in comparison to photogrammetry, looking on one certain line of the surface, photogrammtry seem to has much more inaccuracies and noises in the measurement.

Finally to evaluate the accuracy of tactile scanning with a Kuka iiwa we need much more points and measurable physical points to compare the digital results with the physical structure.

ROBOTIC TACTILE SCANNING is a project of Discretizing Robotic Processes workshop conducted of IaaC, Institute for Advanced Architecture of Catalonia developed at Master in Robotics and Advanced Construction (M.R.A.C.) in 2019 by,

Students: Sebastian Voigt | Apoorv Vaish | Subhash Prajapat | Owaze Ansari.

Faculty: Johannes Braumann | Amir Bastan | Kunaljit Chadha.