SoRo – Lightweight Passive Shading System

[Introduction]

Soft robotics (SoRo) is a fairly recent development in the fields of science and engineering. and it is slowly making its way into different industries, including medicine and architecture. The most prevalent issues of soft robotics can be divided into two main categories. Soft robotics offer unmatched physical versatility and potential. This is mainly due to their flexible and sometimes, elastic nature. As well as their high intractability with a large variety of materials.Pneumatic systems used to power the robots require large amounts of active energy, usually produced by bulky, noisy machines. And the scale at which they can perform architecturally remains unclear.

[Research Question]

Having established a set of drawbacks of soft robotics, Our research question becomes: Is it possible to create a lightweight passive soft robotic system that does not require constant active air pressure and is responsive to climatic changes?

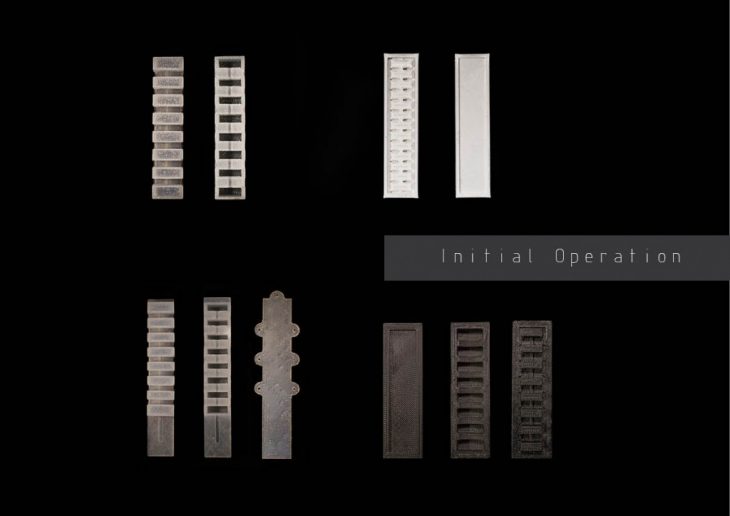

[Initial Operations]

SORO attempts to tackle the two prevalent issues related to soft robotics {First, the methods currently in use to power these robots. And second, is the scale at which these systems are manufactured.} through establishing passive operation techniques and studying the performance of the robotic system in multiple construction scales and applications. This will be achieved through the use of liquids with relatively low boiling points. Making for an easily repeatable pressure system. The system will also be tested for different performances and scales. The initial studies involved silicone pockets filled with various liquids and subjected to heat. These pockets are then left to reach a temperature of 60 C and observations are then carefully documented.

The tests were conducted in a room temperature of 20 C. Each prototype was tested 15 times to insure the repeat-ability of the inflation process. With each test the prototypes were carefully checked for leakage. The Key aspects that we chose to observe are the duration in which the system reaches the desired temperature and the degree of inflation. Other parameters were also changed through establishing a matrix of varying thicknesses and liquids.

[Casting Process]

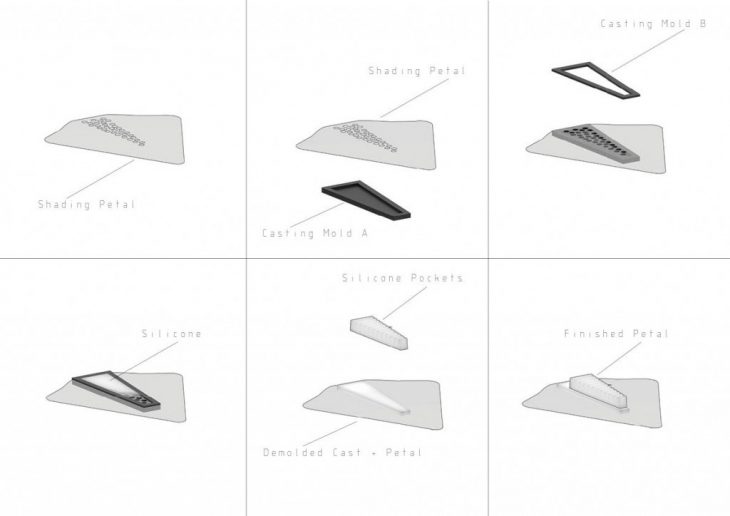

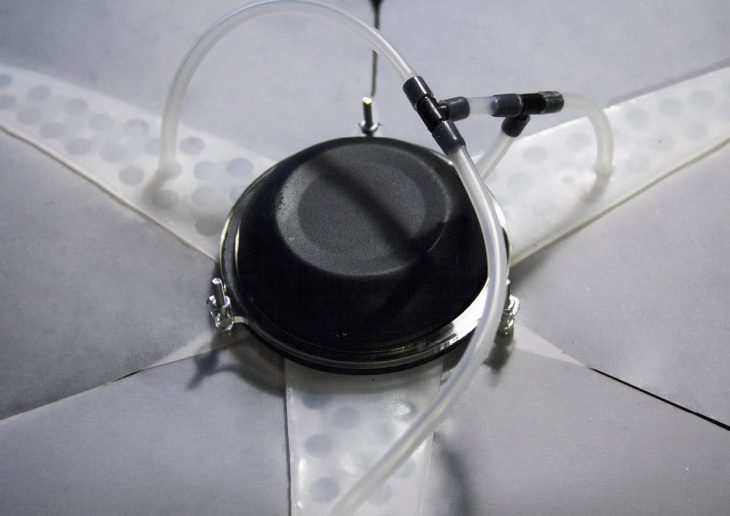

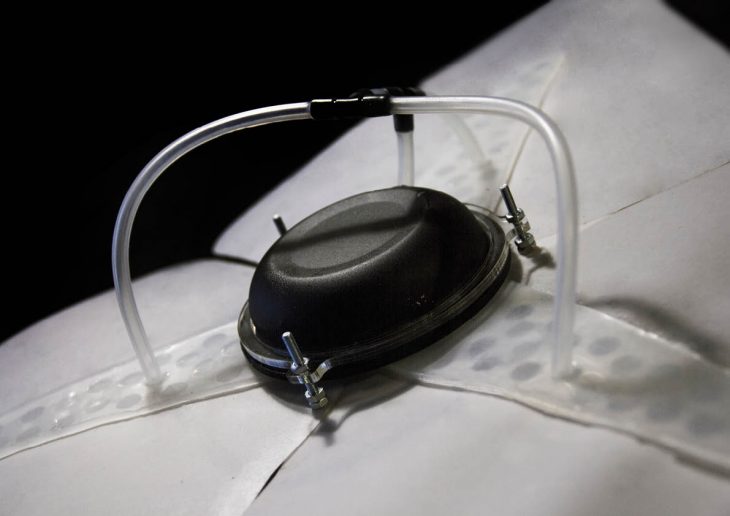

Creating an alternative adaptable passive shading system that is capable of creating a micro climate to accommodate specific uses. Creating an efficient production system for the prototype was quite challenging as silicone was far less predictable than expected. Molds were mainly created via 3D printing and laser cutting. However, the final mold was 3D printed as it had a two part configuration that would have been difficult to laser cut. The active heater was tested with silicone as a protective layer from the liquids as it was to be embedded in the liquid container. The final 3D printed mold was made in two interlocking part and a third mold for the base that would be attached after the silicone is dry. The systems active heating component is integrated within a silicone pad to protect it from liquids. The base and main element were then attached together using silicone as an adhesive and then placed in an oven at 60 degrees Celsius to cure.

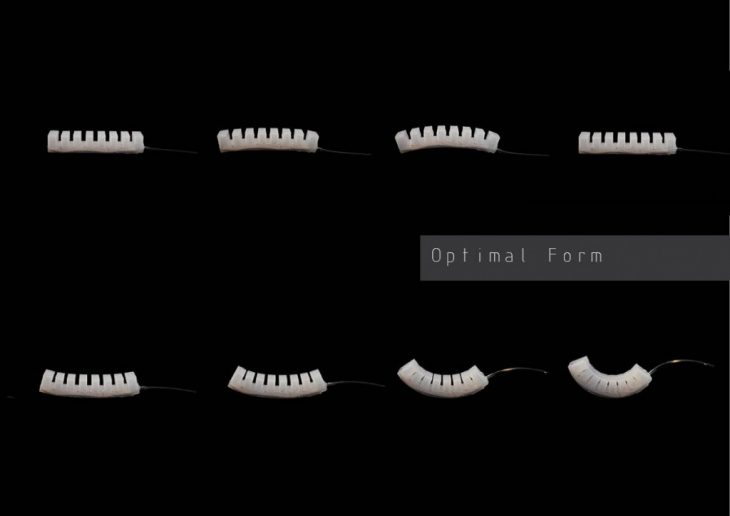

[Optimal Form]

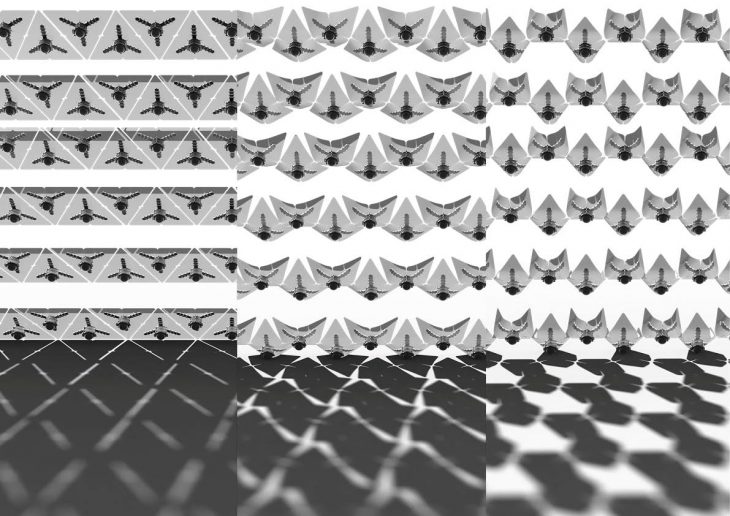

In an effort to provide a more active proprietary heating system for the robots, studies are being carried out to create a simple embedded circuit, which can be controlled and modulated through a micro controller. Upon studying different modes of interaction between the soft robots, one interesting interaction is when those elements are placed on top of each other. This particular performance inspired the way the soft robotic element of the prototype was finally designed. This allows for an over all bending action when a single side is rigidified. This also meant that the system can bend in more than one direction. The pockets are placed in a rib-like configuration as air pressure causes the pockets to push against each other, making the overall system bend in a wide range of angles. This also allowed the system to be bent with “negative pressure” or suction.

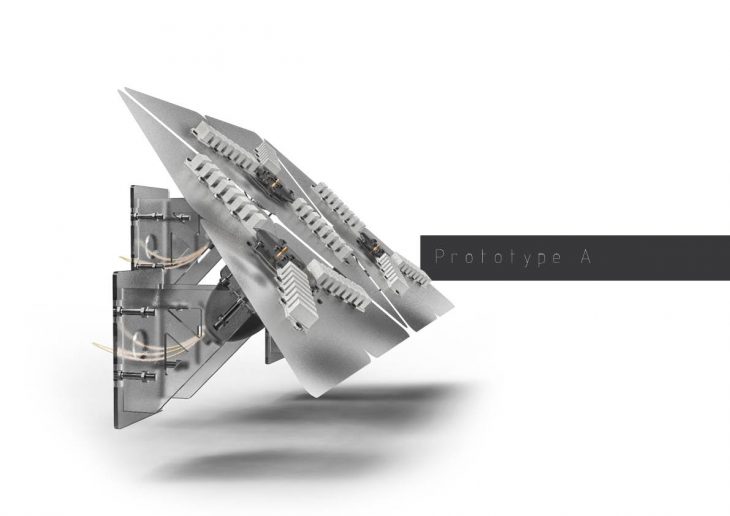

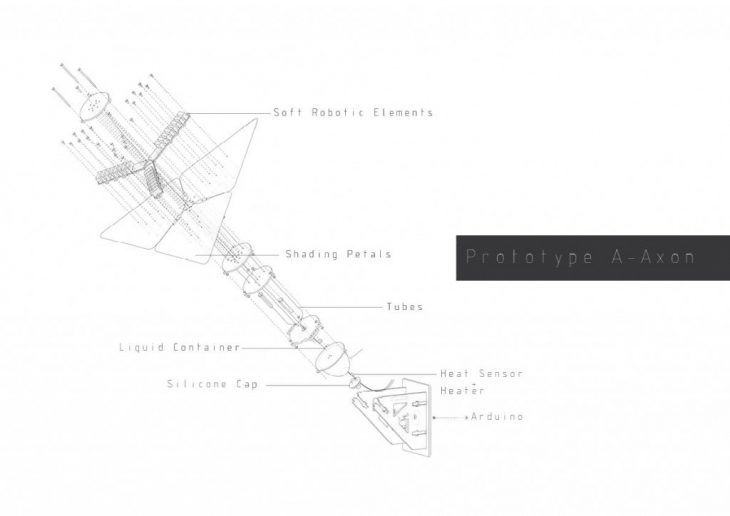

[Prototype A]

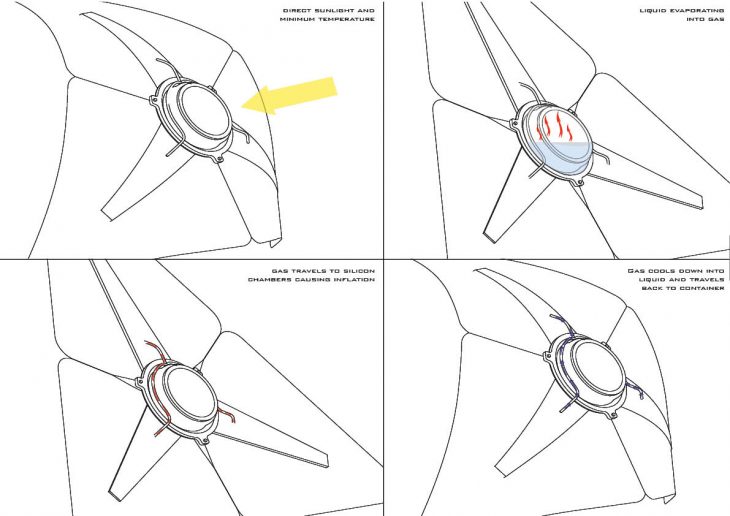

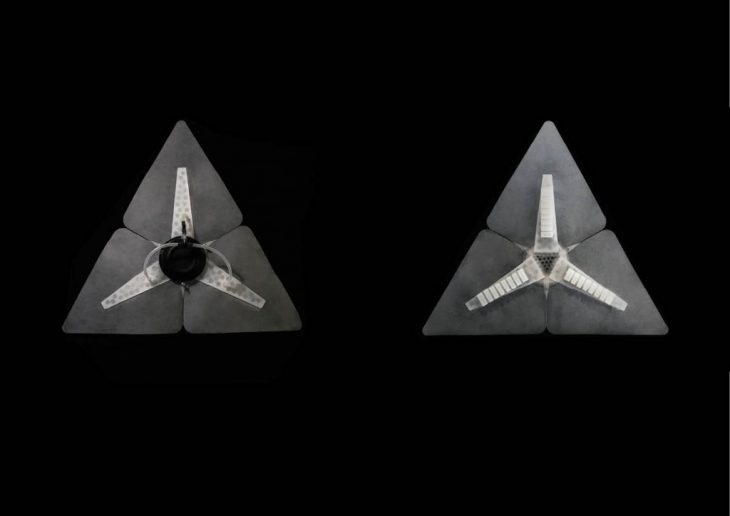

Combining all of our previous research and testing, we developed the preliminary prototype shading system. The system consists of singular triangular units that are operate individually. Through the heating of the liquid inside the container, it evaporates into a gas thus expanding through the piping system into the silicon pockets, causing them to inflate and provide shading. Furthermore, when the heat depreciates, the gas cools back down into a liquid and thus causing the pockets to release the air causing the interesting state of “negative pressure”. In addition, the silicone pockets will remain in that state until the liquid is heated once more.

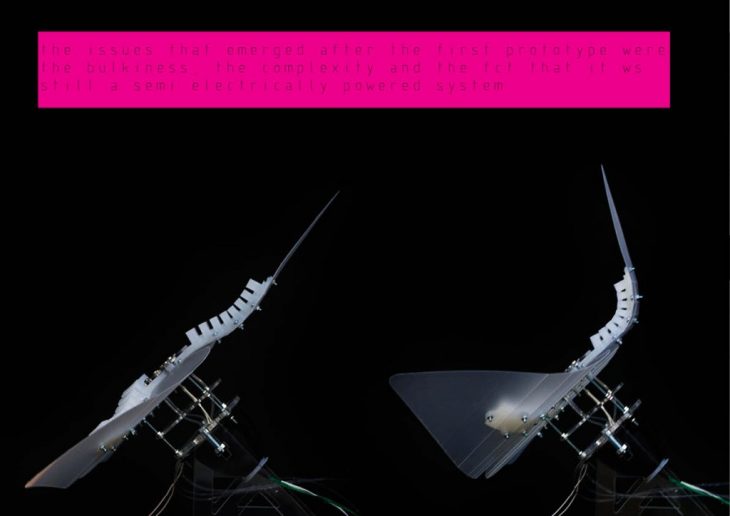

However, after conducting standard testing issues with prototype A became very clear; the bulkiness, reliance on heating through an Arduino, and the limited motion cause by the form of the pockets.

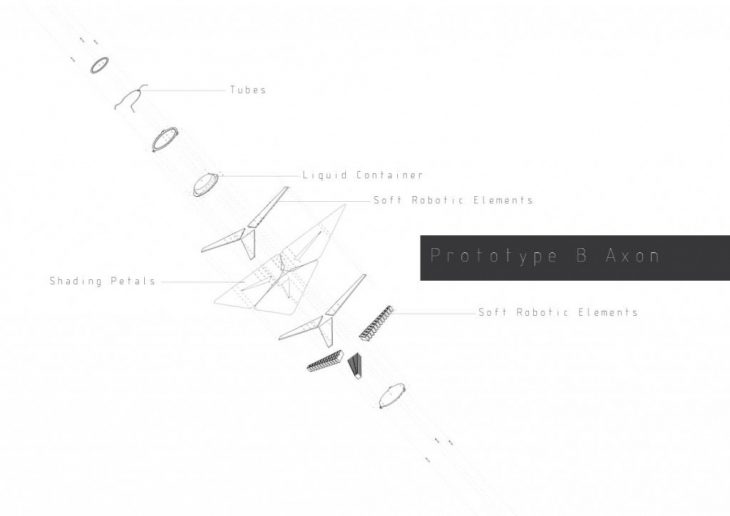

[Prototype B]

The goal of the next prototype was;

creating an alternative adaptable passive shading system that is capable of creating a micro climate to accommodate specific uses.that is light, relatively cheap, and is suitable for a wide range of architectural typologies with easy attachment solutions.

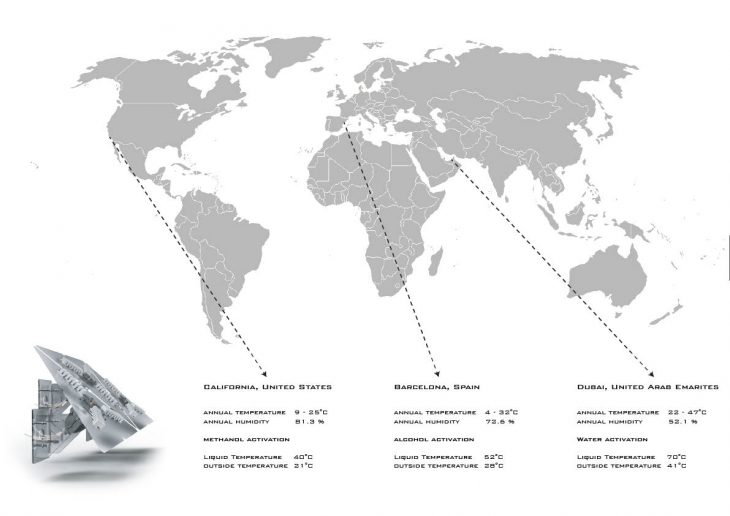

[Global Integration]

The idea behind a completely passive system was very important. With that in mind, it brings forward the two important aspects when it comes to global integration, First, the liquid itself; different liquids have different evaporating temperatures, meaning each liquid requires a minimum outside temperature to activate the system. Second, the threshold of activation; being an entirely sustainable passive system, the threshold for activating the system had to come from a natural source, in this case direct sunlight. Taking Dubai as an example, if the exterior temperature is40 C, direct sunlight adds around 15-20 C to the surface temperature of the now black, metal container, thus allowing for the temperature inside to reach over 100 C, which in turn means water would be the ideal liquid in that situation.

[Preliminary Proposal]

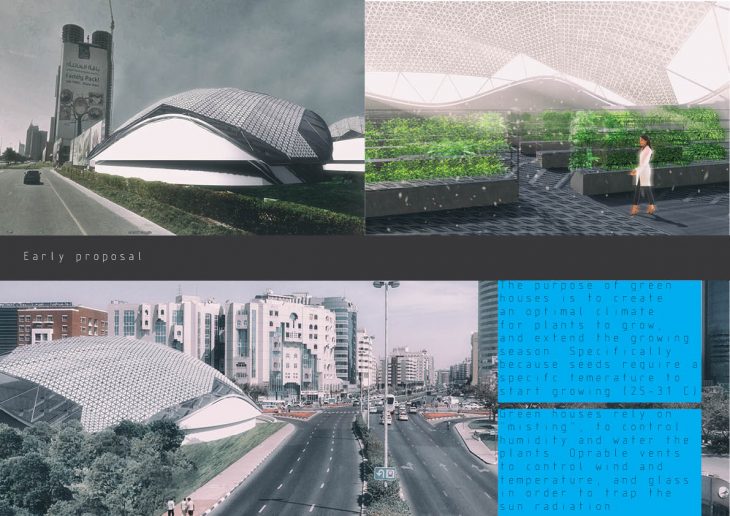

a local set of atmospheric conditions that differ from those in the surrounding areas. One option was to explore the notion of creating a micro climate as the system that can control sunlight, ventilation and temperature, and potentially humidifying the surrounding atmosphere. The purpose of green houses is to create an optimal climate for plants to grow, and extend the growing season. Specifically because seeds require a specific temperature to start growing (25-31 C) Green houses rely on “misting”, to control humidity and water the plants. Oprable vents to control wind and temperature, and glass in order to trap the sun radiation. Greenhouses can greatly benefit from a controlled micro climate. creating a garden in suitable climates where the system can be passively actuated.

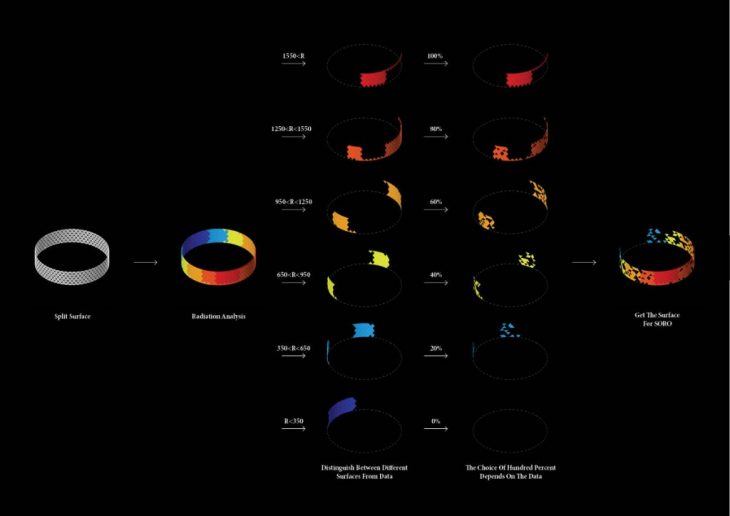

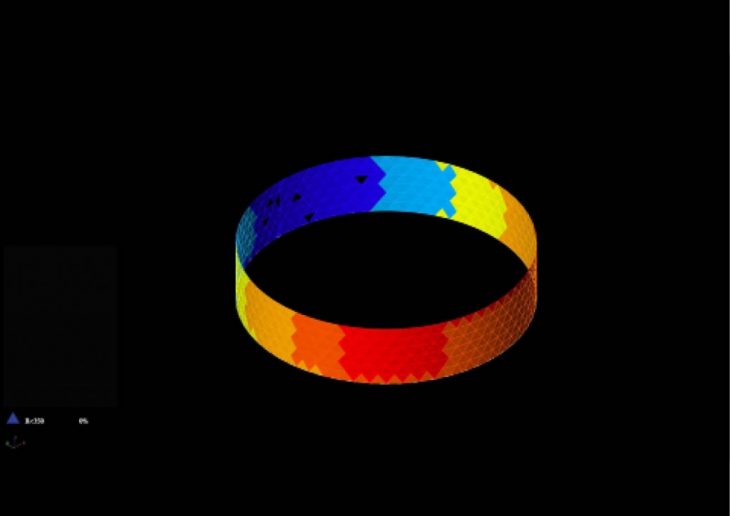

Another possible proposal is to introduce the system to a preexisting architectural condition. One of the key case studies is the Cayan tower in dubai. As the radiation analysis shows a range of possible responses due to the curvature.

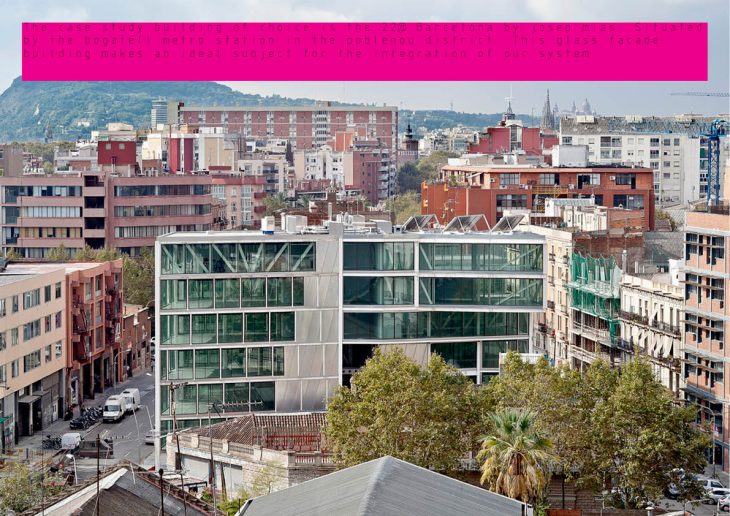

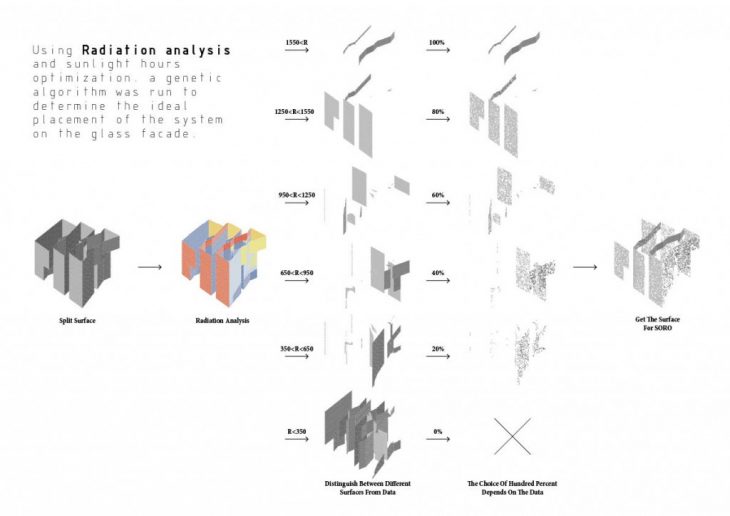

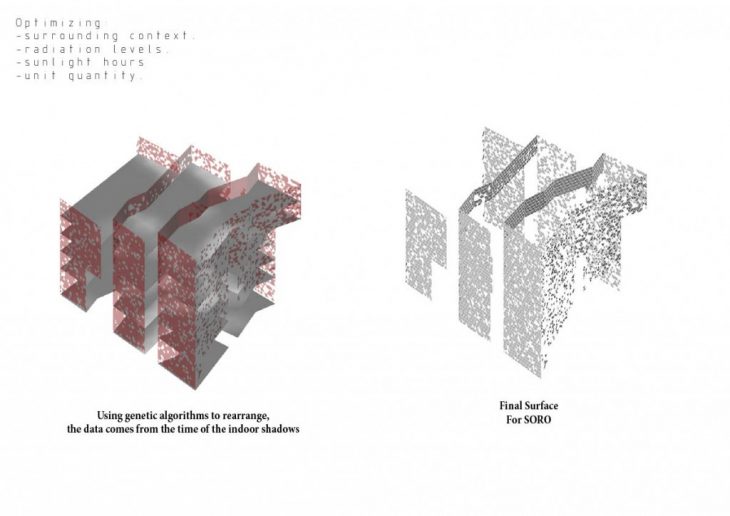

The case study building of choice is the 22@ Barcelona by Josep Mias. Situated by the Bogatell metro station in the Poble Nou district of Barcelona . This glass facade building makes an ideal subject for the integration of our system.

SoRo is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at Master in Advanced Architecture in 2016/2017, for Digital Matter & Intelligent Constructions by:

Students: Nasser Ghannam, Guoliang Zhang, Mohamad Al Chawa, Dongliang Ye

Senior Faculty: Areti Markopoulou

Fabrication expert: Alexandre Dubor

Computational expert: Angelos Chronis