*project as part of the MRAC W1.2 Machine Soulfulness, focusing on robotic craft, in collaboration with Heatherwick Studio

Stick. is an open-ended exploration of digital craft, arguing whether craft and aesthetic sensibilities can be translated and digitally augmented towards defining a new paradigm of construction.

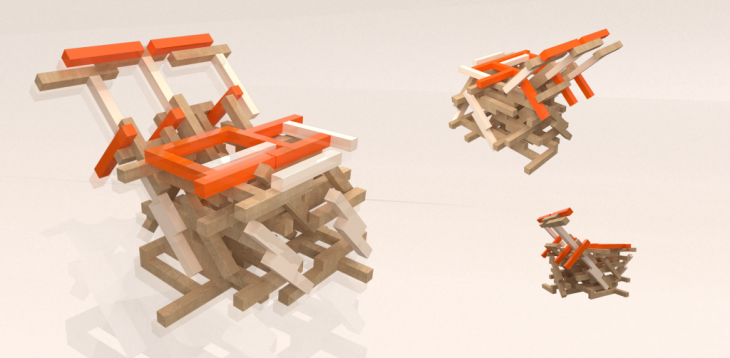

The project aims to robotically fabricate a morphologically complex assembly, starting from embedding behavioural intelligence into a simple building block- a cell. The hypothesis of whether artisanal complexity can be achieved robotically is tested against the brief of fabricating a chair.

- design strategy: embedding digital connection information in a standardised building block

- production strategy: overcome the collision and self intersection constraints for dense morphological aggregations

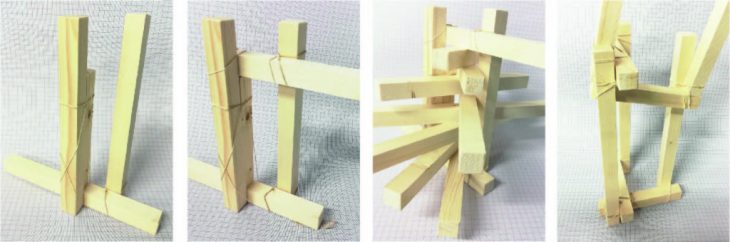

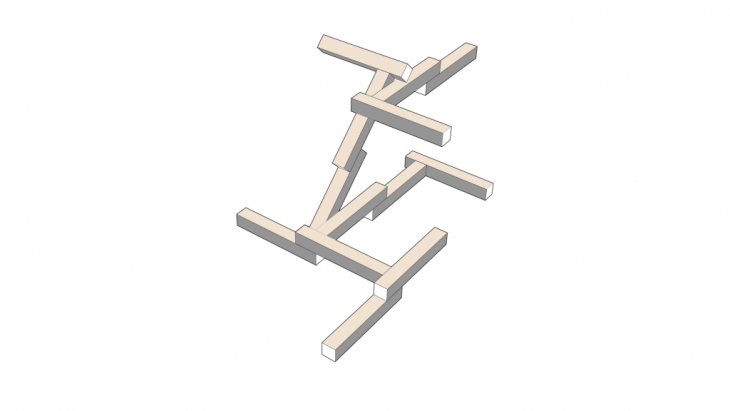

Starting from the characteristics of the basic building block [ 200 mm / 27 mm profile timber sticks] and the basic aggregation agent [superglue] the project commenced with gathering a physical understanding of material properties informing the development of empirical system growth rules.

_PROCESS:

Aligned with the idea of traditional craft, the initial experiments explore the idea of configuration, module and aesthetics through sensorial and intuitive exploration, attempting to gather a rough understanding of materiality and design sensibilities. This stage of the project feeds directly into defining basic behavioural characteristics for later defining the system rules.

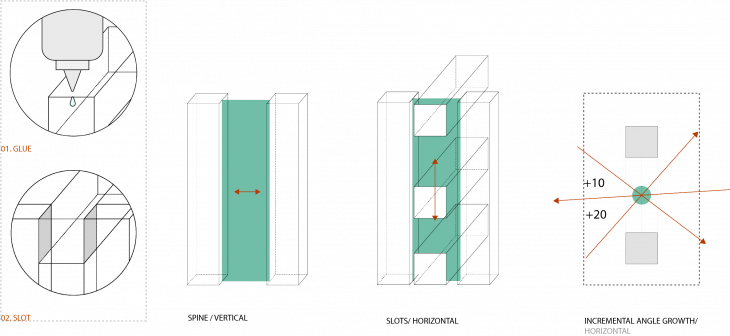

Strategy 01: Spine-based aggregation / mimise number of glued connections / use space-filling joinery in between vertical spine elements

Following an initial interest of embedding biological rules to the system, the initial modular explorations were concerned with understanding sequencial growth paths informed by branching structures.

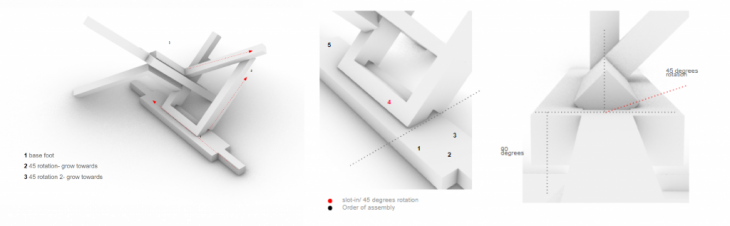

Strategy 02: Module-based aggregation / glued connections for growing in Z direction at 45 degrees / use space-filling joinery in between growth direction determining elements

Strategy 02: Module-based aggregation / glued connections for growing in Z direction at 45 degrees / use space-filling joinery in between growth direction determining elements

_SYSTEM:

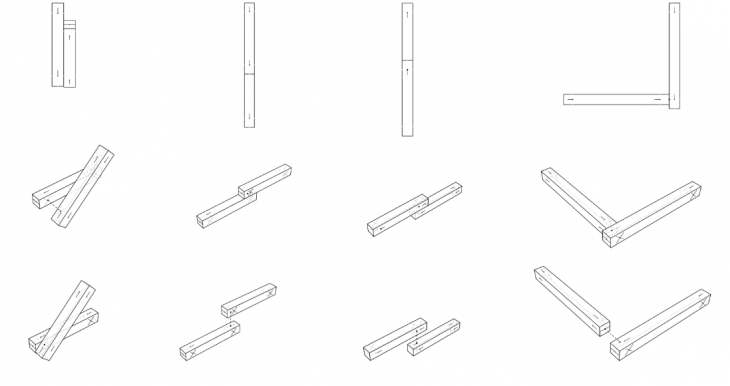

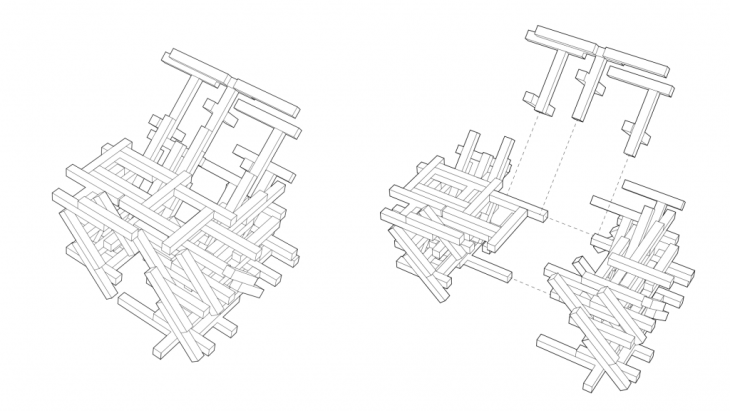

For the next part of the project, a first set of aggregation rules has been defined, setting out a number of possible connections between the building blocks.

General system rules:

- Connection: 2.5 cm from block edge

- Z direction growth: only at +/ -45 degrees

- X direction growth: overlap end to end / +-

- Y direction growth: connect smallest face to length face

Connection points / all possible configurations

W1.2: Stick. / Exp. 01: Process

First experiment expected geometry:

The first experiment informed a series of constraints:

- Tolerances for the base pieces -> 1 to 3 mm

- Collisions with robot setup (glue point)

- Y connection pieces bridged at second level -> glue point problem

- Z pieces at 45 degrees -> glue point connection issue

- double Z pieces at 45 degrees -> angle deformation of initial piece due to gripper force

_PROPOSAL:

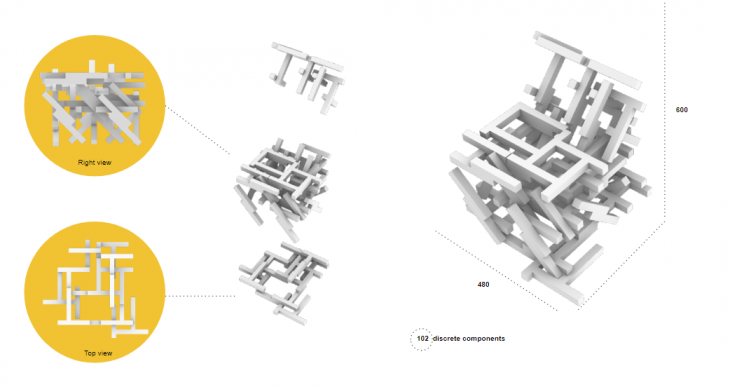

The series of rules used for the final production attemped to solve some of the initial constraints through working with a variety of the first set of rules.

Changes:

- Connection: 6 cm from block edge (increase density)

- Reinforcement: add double pieces in support areas

- Previous aggregation: treat areas differentially

Design constraints:

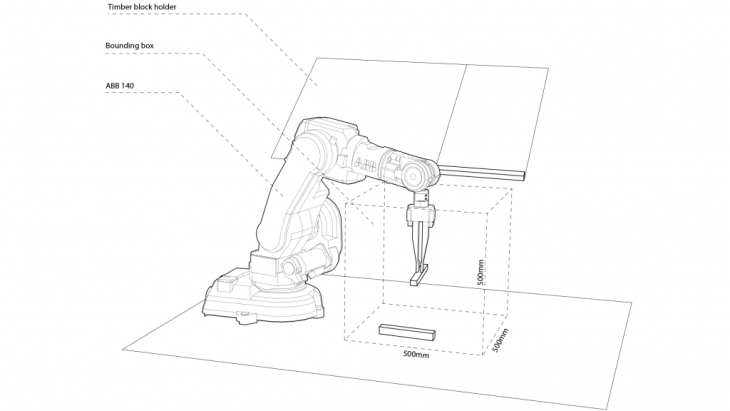

- ABB 140 workspace / bounding box: 500 mm x 500 mm x 700 mm

- Assembly order from -x (build back pieces first)

- Design resolution (building block- 27 mm x 27 mm x 200 mm – proportion to bounding box)

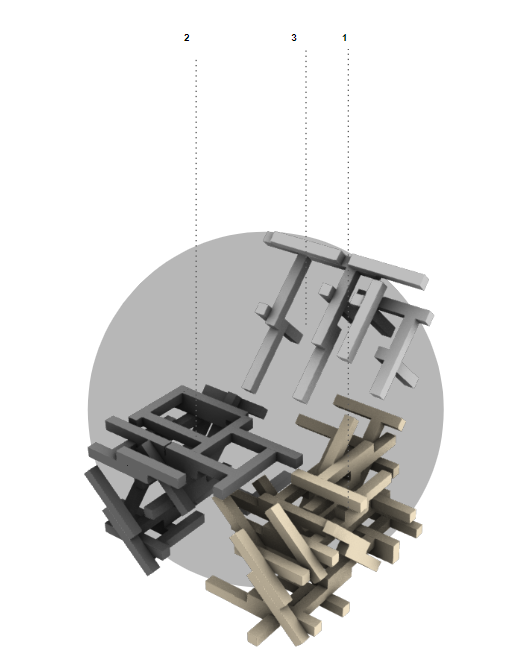

Final design:

Final design parameters:

- bounding box: 500 mm x 500 mm x 700 mm

- grow XY support base up to 50 mm height & for flat seat, grow Z system up to seat height

- 102 components / 5 connection types

Fabrication strategy:

- split final design into 3 pieces accessible in the ABB workspace

- add ‘scaffolding’ to floating pieces after splitting

`

`

W1.2: Stick. / Exp. 02: Chair fabrication

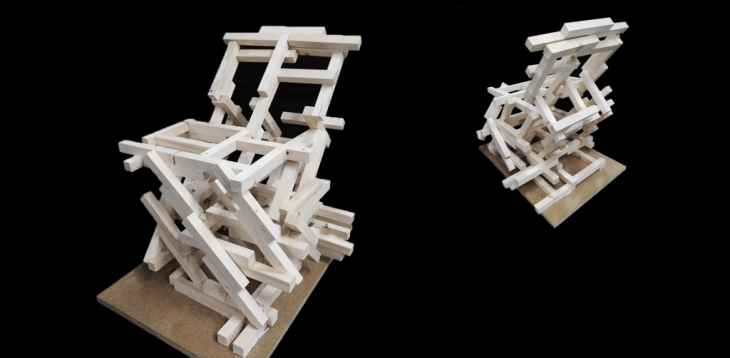

Final prototype physical result:

Stick. is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at Masters of Robotics and Advanced Construction in 2019-2020 by:

Students: Abdullah Sheikh, Andreea Bunica, Jun Woo Lee

Faculty: Pablo Zamorano, Aldo Solazzo, Raimund Krenmueller,

Faculty Assistants: Soroush Garivani, Hazal Yilmaz