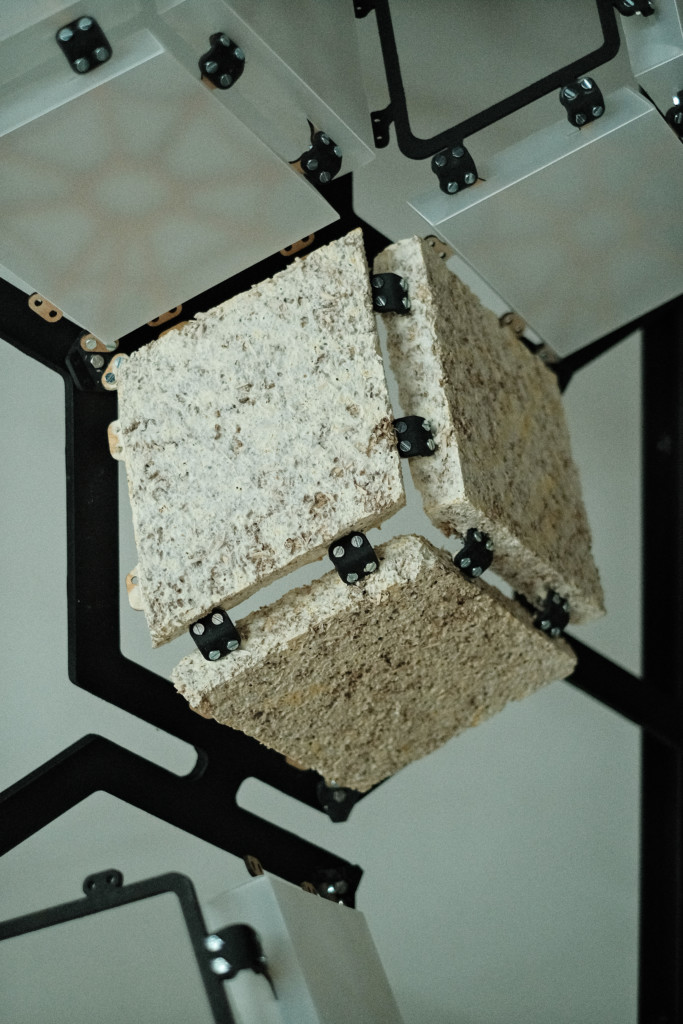

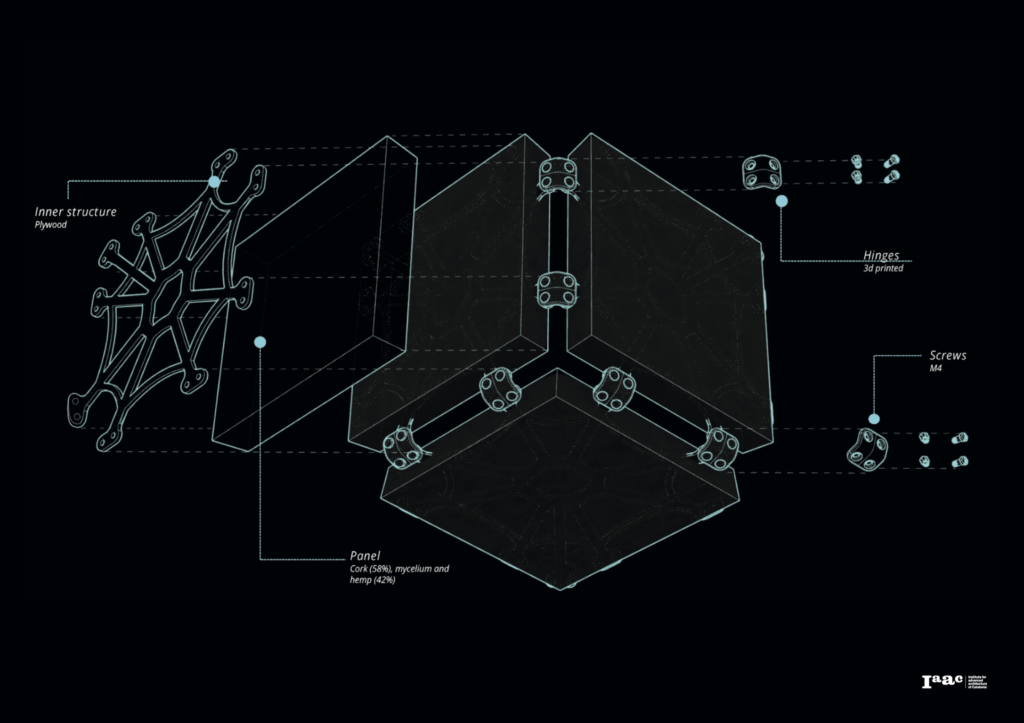

Prototype of Suro//Myco bio composite panels at 1:2 scale

Urban Context: Noise Pollution and the Urban Soundscape

Urban noise is a growing health concern and environmental issue especially as more humans move into densely populated city centers. The prevalence of urban noise is not only affected by the sources of sound, such as vehicular traffic, public transportation, construction activity and nightlife, but also the reflections and transmissions of those sounds by the materials that make up the urban environment.

Noise pollution in cities is not just an aesthetic or productivity concern. According to the European Environment Agency, noise pollution causes 16,600 premature deaths and up to 72,000 hospital admissions per year. Excess urban noise throughout the day and night can lead to complications including cardiovascular disease, hypertension, sleeping disorders, and cognitive impairment, while also being linked to complications during pregnancy, obesity, and diabetes.

Noise pollution heat map of Barcelona

Industrial Context: The Catalan Cork Industry

At the same time, cities are surrounded by waste from commercial and industrial activities that ends up in landfills, which pollutes the earth, or in incinerators, which releases carbon and pollutes the air.

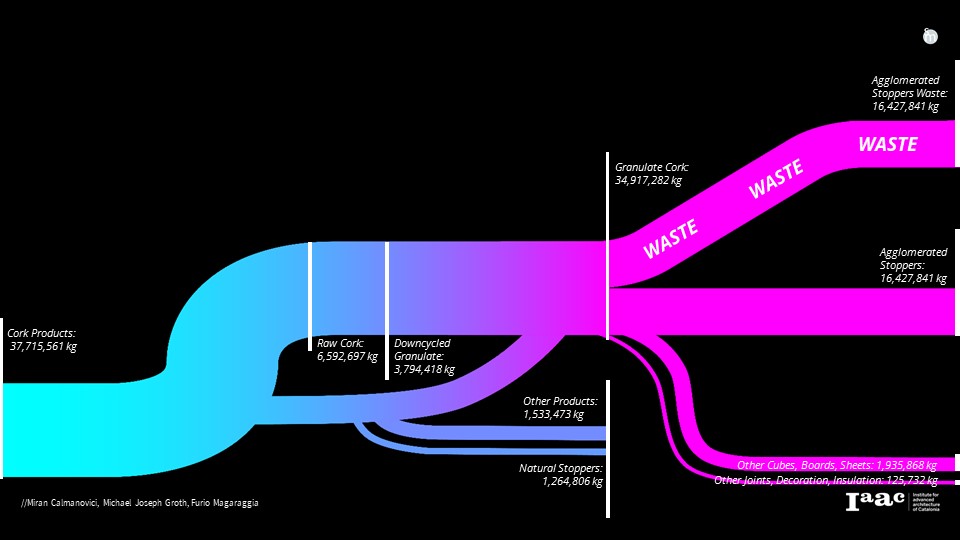

One of the unique industries to Catalonia is cork production. Specifically, the production of agglomerated cork products such as stoppers for champagne and other sparkling wines. As of 2012, Catalan production accounted for 60% of the worldwide champagne stopper production. The cork industry overall is concentrated in the Iberian Peninsula due to the prevalence of cork forests in Portugal and Spain, with concentrations of 34% and 27% of cork oak forest areas in each country respectively.

As a material, cork has many beneficial properties that make it suitable for a variety of commercial, industrial, and architectural applications. Cork comes from the bark of the Cork Oak (Quercus suber), which is able to regenerate its bark every 9-14 years without damage to the tree. This process is able to occur until the tree is approximately 200 years old, making cork harvesting extremely renewable and sustainable. Properly managed, cork oak forests develop into robust ecosystems, increasing water retention in soil, regenerating soil nutrients, and providing a habitat for a diversity of species.

At the microscopic level, cork oak bark is comprised of a closed-cell molecular framework of dead cells. The primary materials of these cells are suberin and cellulose. The presence of suberin gives cork many of its primary characteristics of durability, flexibility, and water resistance, while its cellular structure accounts for its thermal, acoustic, and electrical insulation properties. The combination of suberin and the closed cell structure give cork its high strength to weight ratio compared to other biomaterials.

While cork has many beneficial properties and sustainable harvesting methods, the realities of production lead to high levels of waste. The production of whole cork stoppers, primarily in Portugal, utilizes only 25% of the input material, although much of the waste is downcycled into other products. In Catalonia, the primary production is focused on champagne stoppers and other agglomerated cork products. Production of these stoppers utilize around 50% of the input material (cork granulate) while much of the waste is captured as biofuel to be used as heating for production.

Sankey Diagram of Cork industry in Catalonia

Research Question

Could we harness this waste stream and use it to improve the health and enjoyment of urban life in Barcelona?

When considering possible solutions to the issue of urban noise we defined a set of design protocols to help guide our research and experimentation. These protocols include retrofitting, design for disassembly, circular material cycles, and waste upcycling. We followed these initial protocols to further narrow our focus to designing with living systems and biodegradable waste.

Suro//Myco Design Protocols

Initial Tests

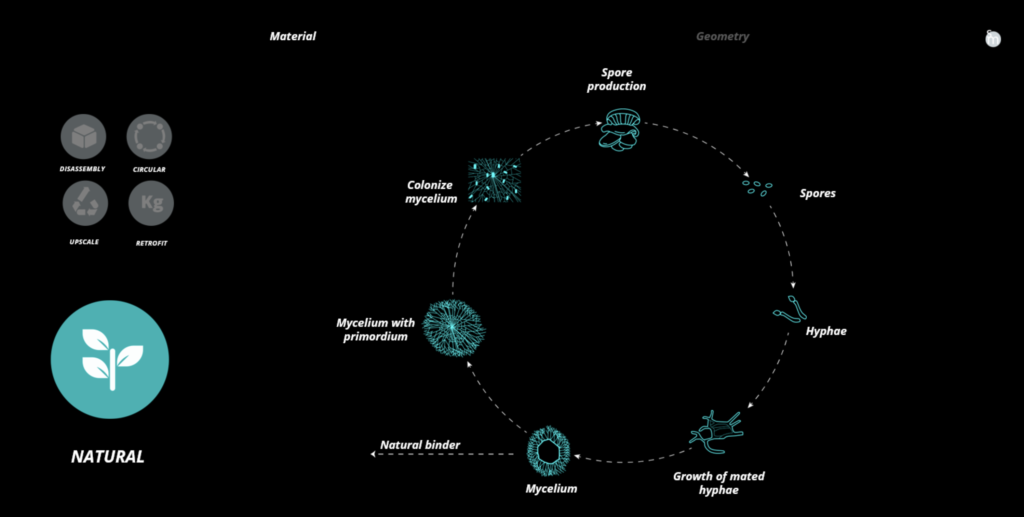

Following our design protocols to find a lightweight, low-energy solution, we researched using a living system as a binding agent. Mycelium presented itself as an excellent candidate to complement the natural properties of cork in our material system.

Mycelium is the root-like structure of fungi which acts as a nutrient-absorbing network of threads, or hyphae. The biotic function of mycelium in its natural environment is to break down and decompose organic matter into simpler organic and inorganic compounds, adding nutrients back into the soil for other organisms to absorb. In an appropriate substrate, mycelium will expand from spores into a dense network of appendages, binding to organic matter and releasing enzymes to break down materials including lignin, cellulose, and suberin. Once mycelium has propagated thoroughly through a substrate, the material can be dried or heated in order to suspend or kill the mycelium, leaving a lightweight structure with varying characteristics depending on the structure and makeup of the substrate.

Mycelium-based composite materials exhibit the following characteristics: low density, hydrophobia, thermal insulation, and acoustic absorption. These characteristics can be highly customized based on the structure and density of the substrate material. Based on these characteristics we found mycelium to be highly suitable for composition with our cork granulate and pursued further research in material prototypes.

As our focus for this research is acoustic absorption within an urban environment, we found further complementary properties between cork and mycelium. Studies of mycelium composites find that across many agricultural waste substrates, mycelium composite materials perform well in absorbing frequencies from 1000 Hz to 2000 Hz. Rough cork surfaces performed well between 300 Hz to 800 Hz while smooth cork surfaces exhibit a wide range of absorption from 1000 Hz to 5000 Hz. Thus by combining cork granulate with mycelium we can expect favorable absorption of frequencies of the primary sources of urban noise, with car and truck traffic creating sounds in the range of 500 Hz – 1600 Hz and the human voice creating sounds in the range of 100 Hz to 300 Hz.

Mycelium lifecycle diagram

Further Studies: Material Prototypes

We began our material prototypes with a substrate of cork granulate with cork stoppers placed in specific patterns in order to utilize the properties of the rough cork surfaces of the stoppers with mycelium and cork granulate composite in between. The mycelium and granulate mixture was able to bind fairly well, however the structures were weak at the points where the stoppers were inserted. Based on these findings we elected to focus on creating panels with only the cork granulate as a substrate in order to maintain structural integrity.

In further material prototypes we tested various combinations of cork with other organic waste materials to improve the growing process of the mycelium and improve the strength of the panels. We tested combinations of cork granulate with both hemp and coffee grounds, which are both an easily digestible source of nutrients for Pleurotus ostreatus. The mycelium was able to grow well with all of the substrates, however the hemp hurd waste provided the best strength in the final panel due to its fibrous structure. We elected to continue with a 3:2 ratio of cork granulate to hemp hurd as the substrate in order to take advantage of the greater strength of the hemp along with the acoustic properties of the cork.

Detail, Suro//Myco Prototype at 1:2 scale

Panel Detail, Suro//Myco Prototype at 1:2 scale

Computation / Optimization strategy

The other side of our research was a computational simulation analysis of acoustic behavior in the urban environment. We generated a variety of simple geometries on a typical building facade in order to understand the behavior of sound waves generated at the street level. With an understanding of the urban canyon effect we aimed to maximize the absorption of sound waves on the panels (primary bounce) while minimizing the number of sound waves reflected back to the street or surrounding buildings (secondary bounces).

We started our analysis by building cross sections of typical streets in Barcelona and applying a secondary skin of louvered panels to a building facade. We utilized Pachyderm, a ray-tracing algorithm for Grasshopper, in order to generate a regular array of rays from a point source in the center of the street and measure the number of primary, secondary and tertiary bounces off of the selected building, the panel structure, and the surrounding environment. We used a genetic engine for Grasshopper, Wallacei, to run an optimization analysis maximizing the bounces against panels, minimizing reflections to the surrounding environment, and minimizing surface area of the panels.

The preliminary analysis led us to conclude that flat panels were more efficient than curved panels in terms of acoustic absorption per surface area of material. Because of the lower incidence angle there was also greater efficiency of absorption when panels were concentrated towards the lower heights of the building.

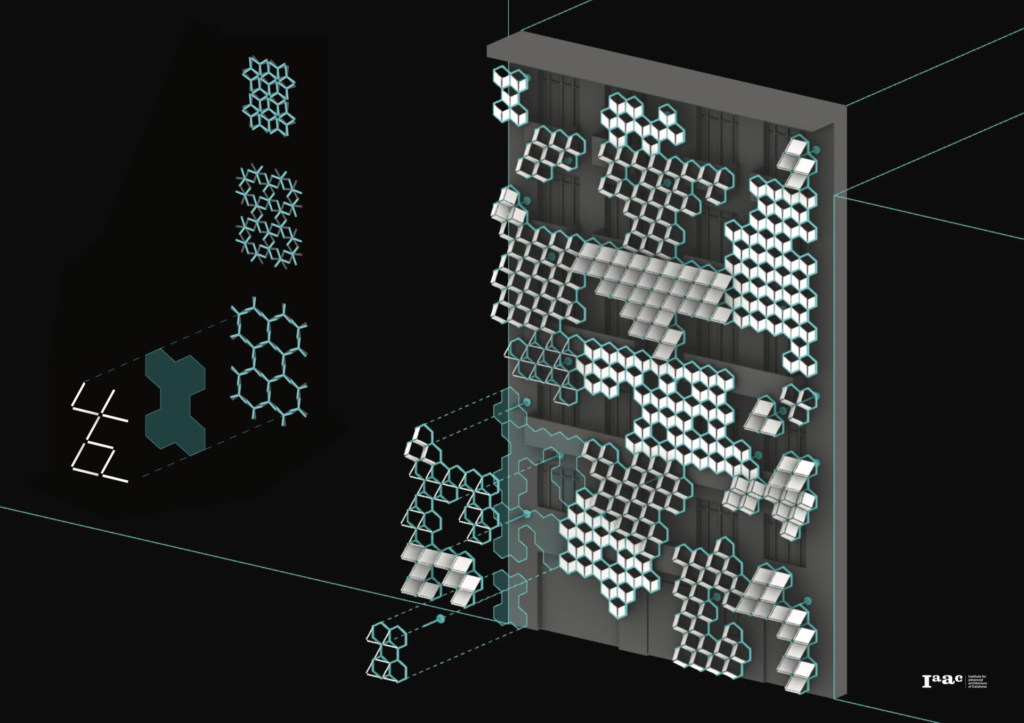

Final selections of optimized geometry for suro myco case study

Suro Myco case study, exploded components

Final Design & Optimization Strategy

For our final design we focused on streamlining the structural elements in order to facilitate deployability and adaptability. This led us to further discretize the assemblies and simplify the structural attachments.

Elements of the assembly are classified into modular and customizable components. Modular elements such as the substructure and support beams are made of durable and reusable materials such as aluminum or steel. Customizable components are limited to the materials that can be grown cheaply and recaptured as nutrients for soil, including the cork, hemp, and mycelium composite as well as the laser cut wood substructure for the panels. Finally, connecting brackets at specific angles made of aluminum secure the panels to each other and to the substructure, and can be reused or recycled based on future requirements.

For the optimization we start with the underlying facade surface, divided into solid surfaces and voids (for windows, ground floor shops, etc.). Support beams are placed based on the arrangement of the solid surfaces. From the facade surface we generate a hexagonal grid, with the size of the cells based on the scale of the building. According to solar requirements and wind loads on the secondary skin a percentage of the cells are dispatched from the grid.

From this dispatched grid, cells are grouped into clusters based on the nearest support beam to each cell. At this stage, any orphan cells (single cell clusters or cells with a single contact point to their cluster) are removed for structural efficiency. This grouping of clusters is then populated from a preselected catalog of panel options, with variation in number of openings and depth of modules.

The genetic engine optimization seeks to 1) minimize the surface area of all panels 2) maximize the primary bounces on panels based on ray tracing from a predetermined sound source to a regular grid on the facade and 3) minimize secondary bounces against other elements in the environment (the street surface and surrounding buildings).

Exploded components of Suro//Myco module

Conclusion

Suro // myco is one local solution to a global problem of urban noise pollution, however the framework and approach can be employed anywhere. By using the circular material flows provided by biocomposite materials it is possible to start to improve our urban environment without having to rebuild existing infrastructure. The affordability and adaptability of these materials allow us to design with evolution in mind, rather than designing towards a perceived permanence. While solving for the issue of urban noise pollution may not seem to directly help the environment, increasing the livability of cities means that more people can find a lifestyle suitable to their needs within a greater sustainable urban framework.

Suro//Myco is a project of IAAC, the Institute for Advanced Architecture of Catalonia, developed during the Master in Advanced Architecture (MAA01) 2021/22 by students: Michael Groth, Furio Magaraggia, Miran Calmanovici; Faculty: Areti Markopolou, David Leon; Faculty assistant: Nikol Kirova, Eduardo Chamorro Martin; Student assistant: Alexander Dommershausen.