Visual Filter

'Visual Filter' in performing space

Visual Filter is a project done by Baran Tehrani, Lars Erik Elseth, Mohor Bose and Ewald Jooste.

The attempt of the project is to develop spatial patterns at the scale of an architectural object using laser cutting through folding techniques.

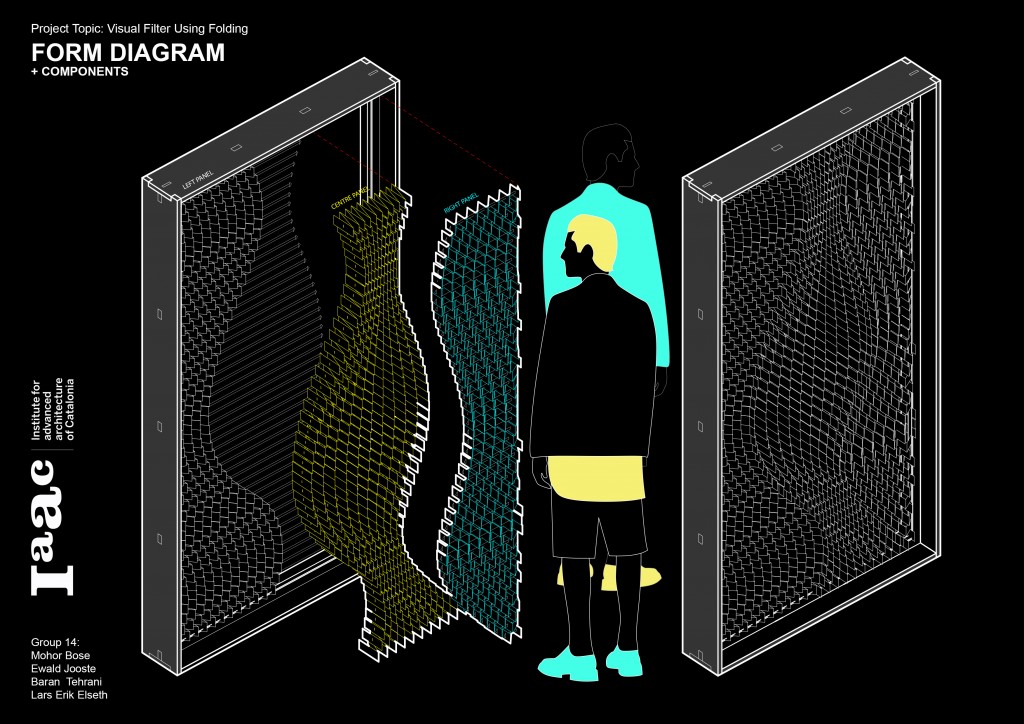

We were provided with an empty rectangular frame made of plywood (of internal dimensions 2000 x 1000 x 180 mm) for which a filling needed to be designed and manufactured in 1:1 to create a final product that would be used as a space divider in the open studio area.

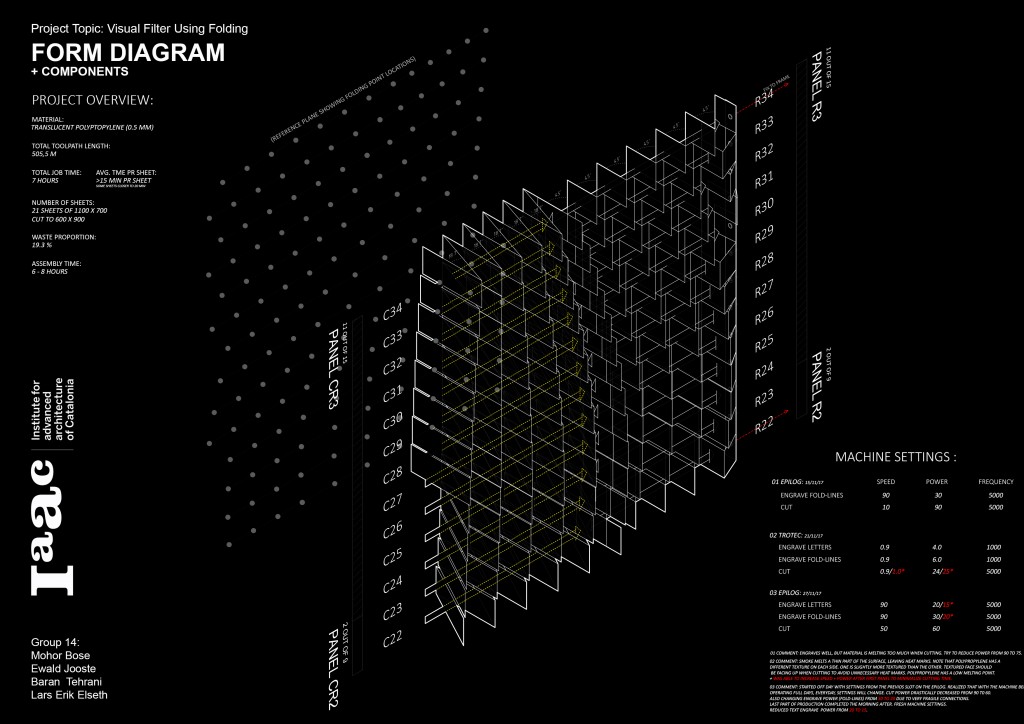

The concept of our group’s project was to use the pop up origami folding techniques in order to give a conception of density and translucency and to reach different gradients of light. In order to reach this goal, we chose a specific fold and tried to play with different attributes through amplitude and density. The material that we used for this project was translucent 0.5 mm polypropylene.

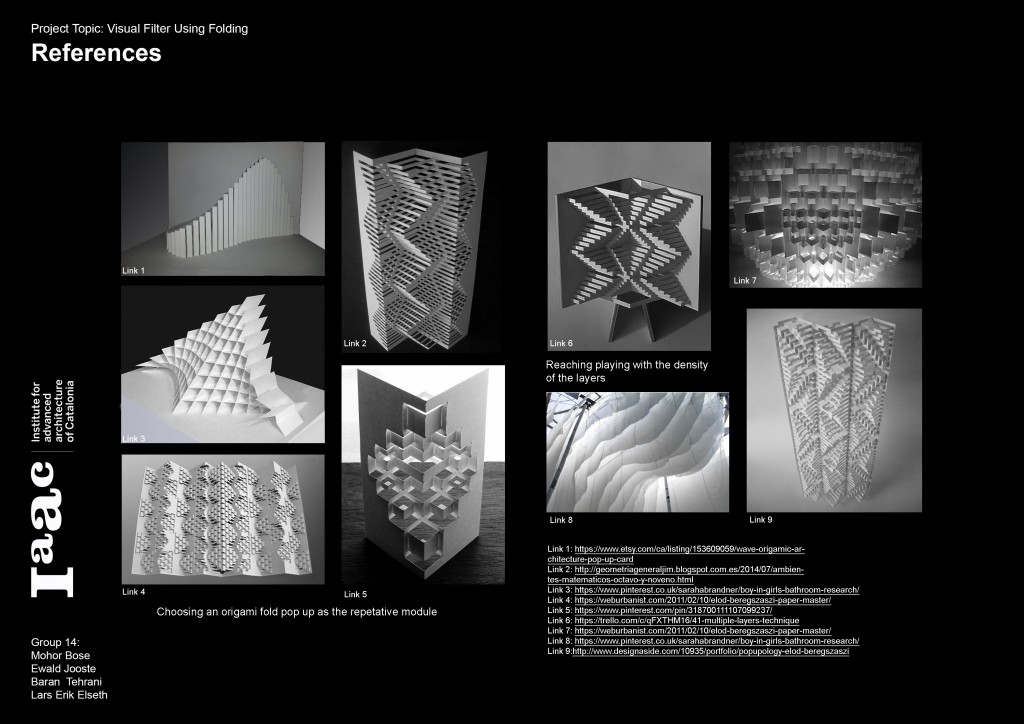

Inspiring References

Conceptual Diagrams

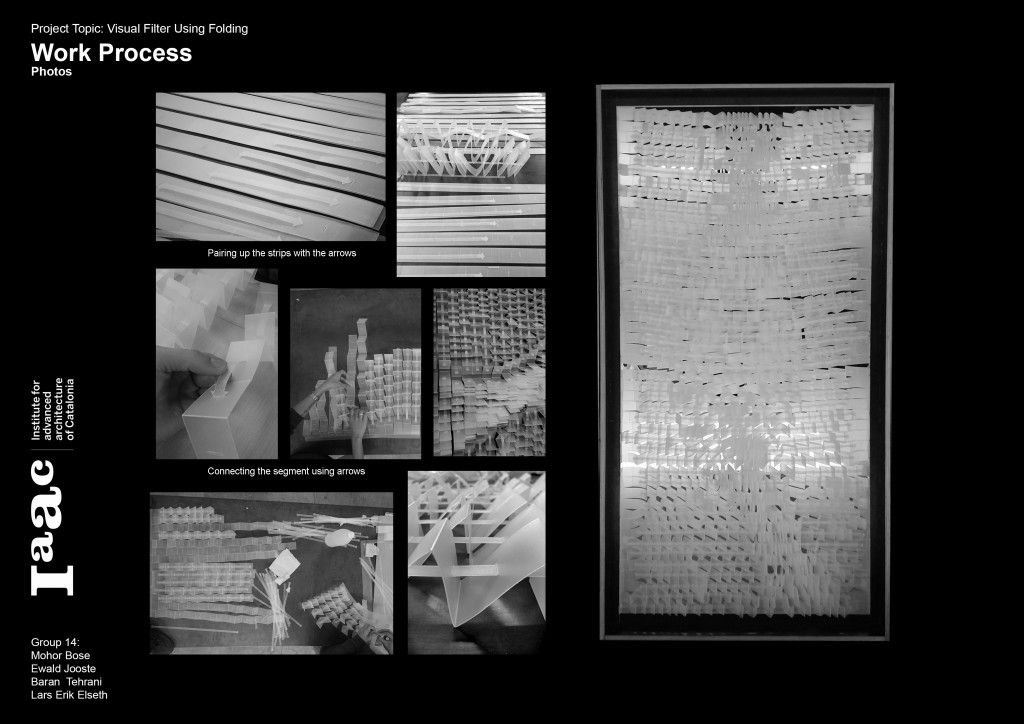

Work Process

Technical Information

Summary

After having gone through a series of iterations and completed the final design we see that our folding design performs in various densities and are able to filter light. Fold-lines generated by a divide-line operation in grasshopper turned out to be very translatable in fabrication. We see a potential for controlling these folds based on other inputs, turning the system into a kinetic one. The method of construction is first of all consisting of a number of assembled panels that then are either joined together by other panels on either side, or fixed to the frame.

These panels became helpful for organizing the workflow, but their assembly could be rationalized further by reducing the amount of folds, widening the openings for the joinery arrows to go through, and in general; scaling up the design. One of the challenges we faced was being able to hold the folded strips in place. Once it was mounted onto the frame it started to sag in areas where tension was too low. The folds created geometric strips that somewhat exists in a state between a stretched and a fully compressed structure, making it necessary to introduce another structure-system to keep it in a constant state (arrows). The arrows should be designed in such a way that they lock the folds in one place, by for example a notch edge-treatment. An alternative could be to accept the movement, and allow the design piece to move within a certain boundary. Lastly, we realized that we could also accomplish a stabilized structures through hanging it rather than stacking it.

We would like to give recognition to the people that helped us in the process;

Alex Dubor

Raimund Krenmuller

Ricardo Valbuena

Sebastian Moreno

And a special thanks to Ricardo Mayor which has been very patient with all of us, as we progressed through our very first 1:1 fabrication project.