Cross Laminated Timber is chosen as a material for this year’s tiny house structure. The Voxel is composed by CLT and offcuts of the wood for CLT lamellas. CLT production process has started from cutting the trees in the master’s own property to wood processing in the carpentry locating in Valldaura Labs.

After we had made a research and communicated with companies doing CLT, we started to process by doing a small prototype. The institution bought a press machine in order to glue lamellas to each other.

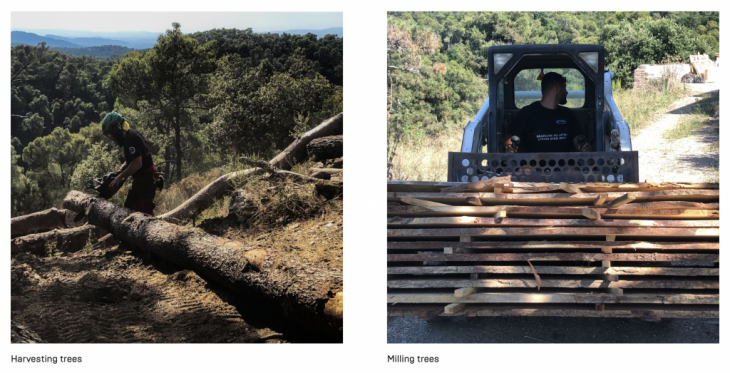

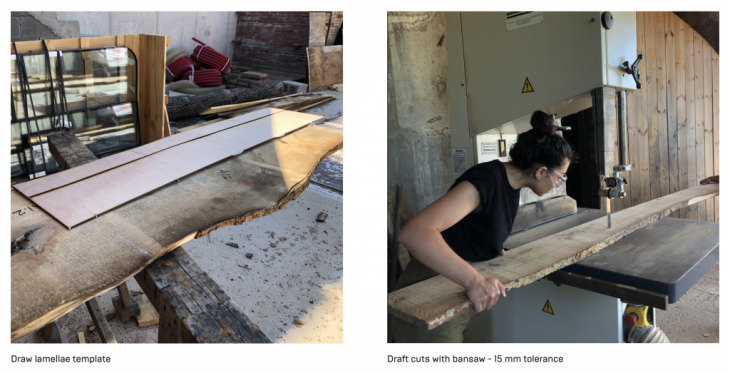

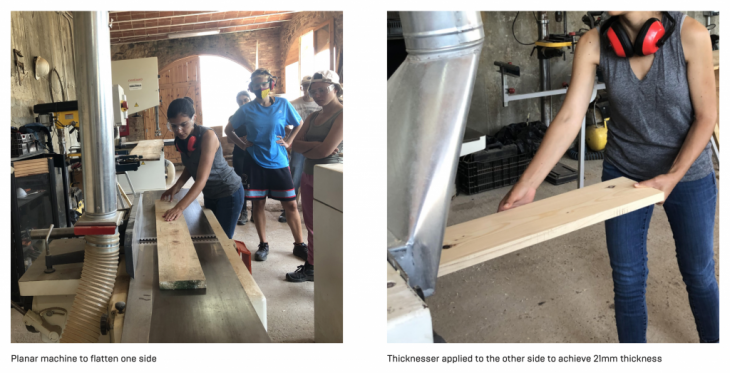

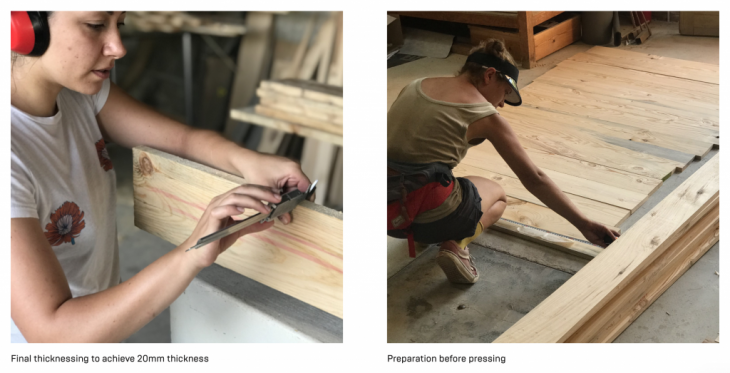

The first step was to cut down the trees by the help of lumber jacks. The selection of the trees were important to keep balance in the forest. Ecological forest management requires to select collect trees to be cut down not to damage the forest and protect from fire. After cutting the trees, we sliced the trunks into pieces with thickness around 30 mm. We left the wood to dry for approximately 6 months. This process is shaping the future properties of the wood so it is very important. We located the wood on a structure and between the each later we put separators in order to prevent bending and cracks. We grouped pine wood and oak in different piles. After the wood is dried, we took them into the carpentry to process them and formed into lamellas with certain dimensions. Preparation of lamellas starts with drawing them on the sliced raft wood with extra dimensions for error. The width of lamellas is standardised to be 150 mm. After drawing step, first cuts are done in the band saw to proceed with planar. After one side is planed well on the planar, wood is processed in the thicknesses to reach 21 mm approximately. Since we have plane surfaces, we are able to achieve two straight edges by the help of table saw. As final step, the last two edges are cut in the chop saw to achieve the final length we want. CLT panels are designed to be formed by 3 layers with the final thickness of 60 mm.