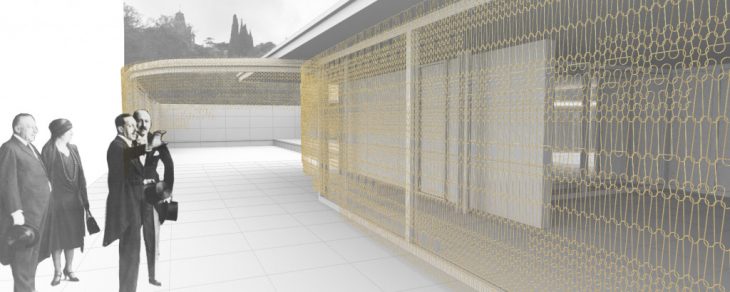

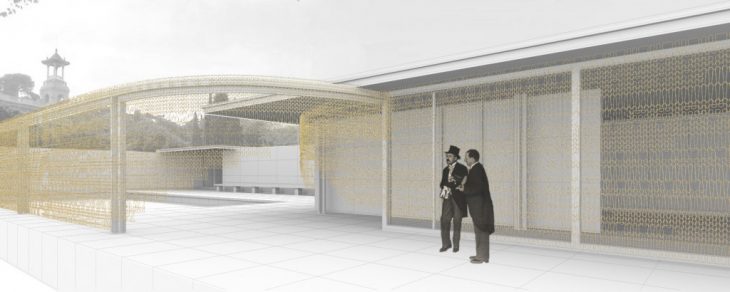

An architectural façade exploration that allows different control of privacy or solar control. The size of the piece can change depends on the size of the project or the aesthetics searched.

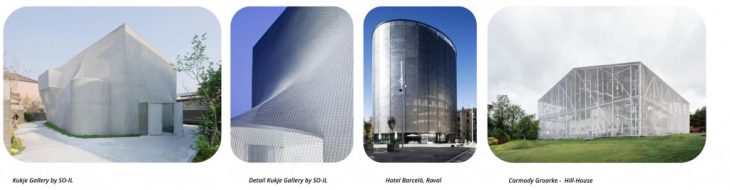

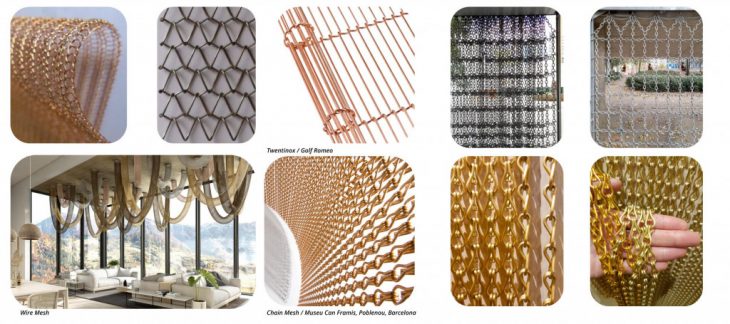

State of the art

The aim of this project was to study a system that allows create customizable wire mesh. In the context of wire mesh, the state of art in this area exists different approaches that are too complicated to install or regular patterns with inefficient uses of the material. Our project takes these points and tries to make a modular product that is efficient in the use of the resource, it creates different patterns, densities and lightness.

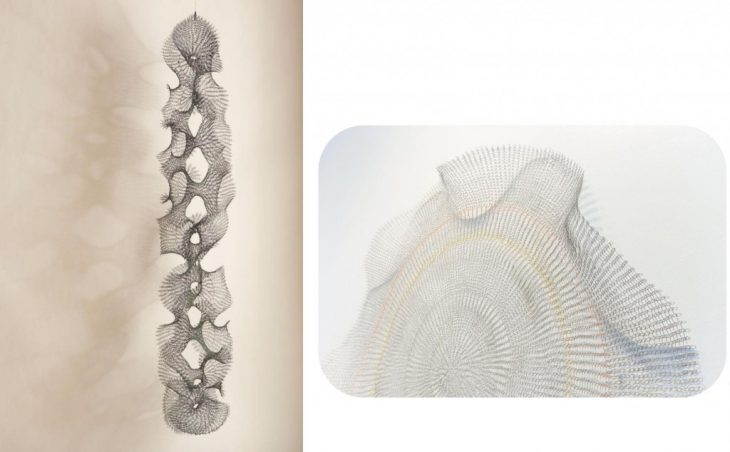

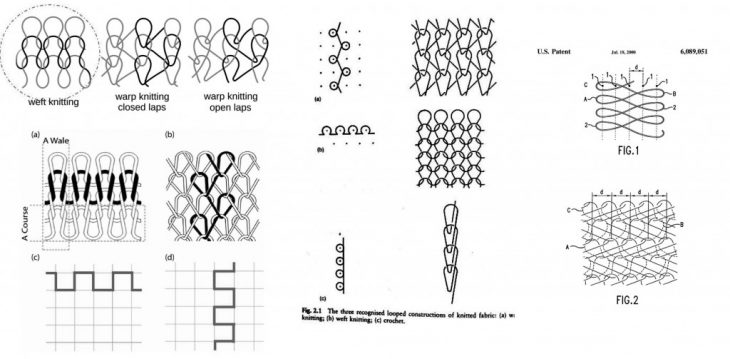

This idea provides from the studies of different artist that explore the knitting’s technique, specifically Weft knitting.

Aesthetical References. Wire [Ruth Asawa. Looped Wire Sculptures][Indira Urrutia. Wir]

Aesthetical References. Density and knots [Mary Walker Phillips. Lace panel. Art Institute Chicago. 1960s]

Weft & Warp Knitting

How it works

Discrete Geometry-related aspects

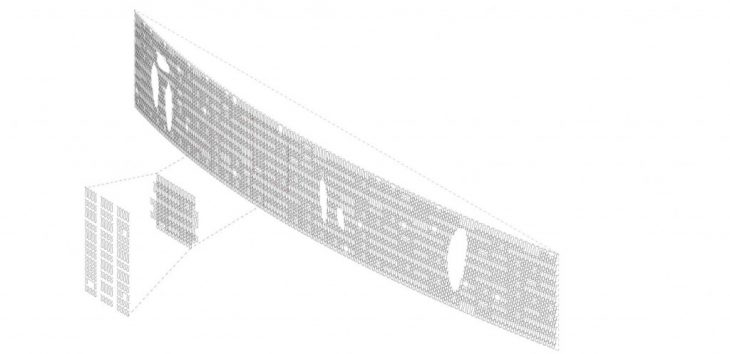

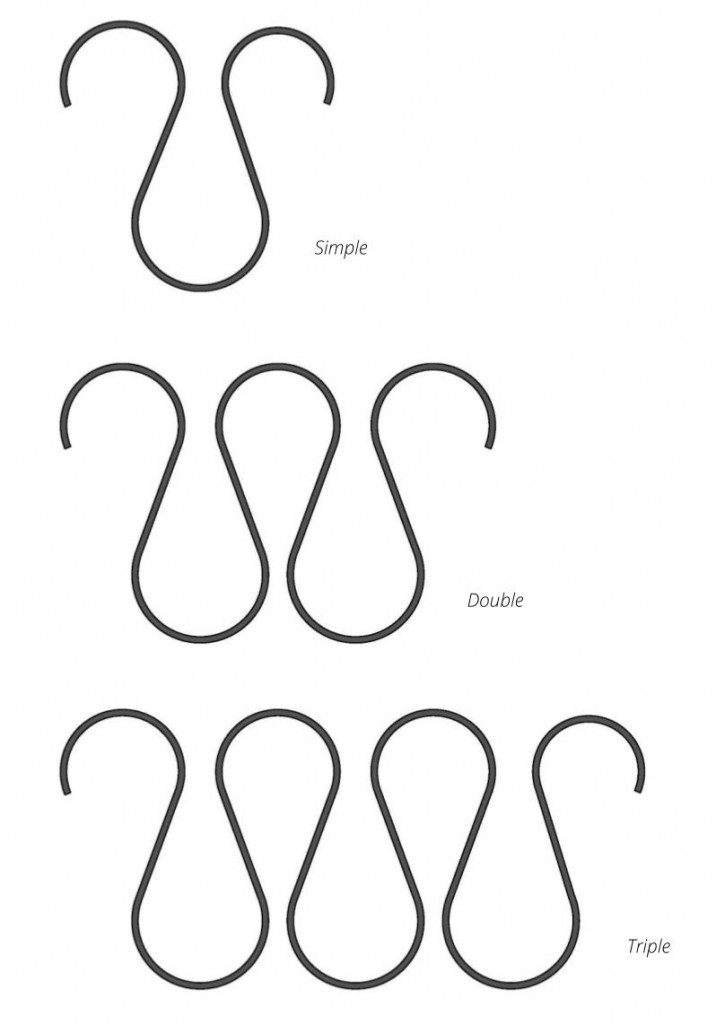

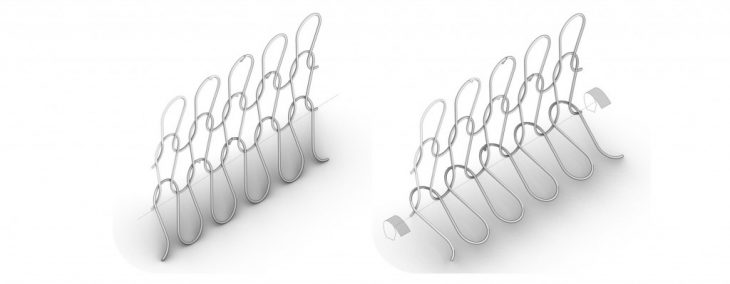

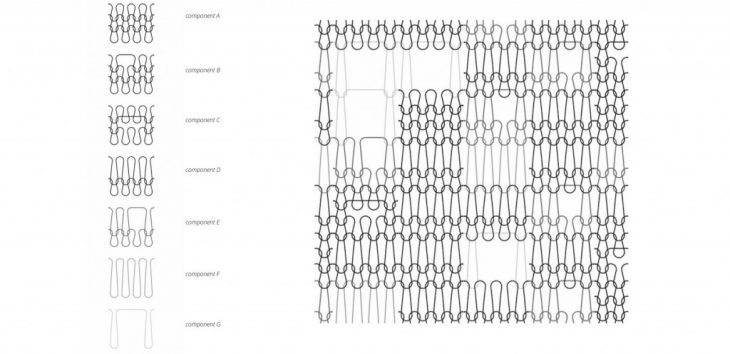

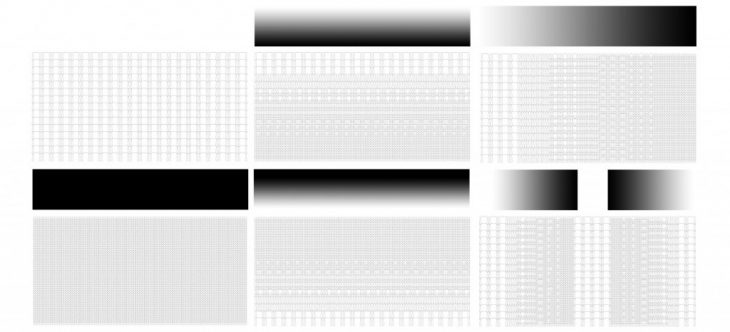

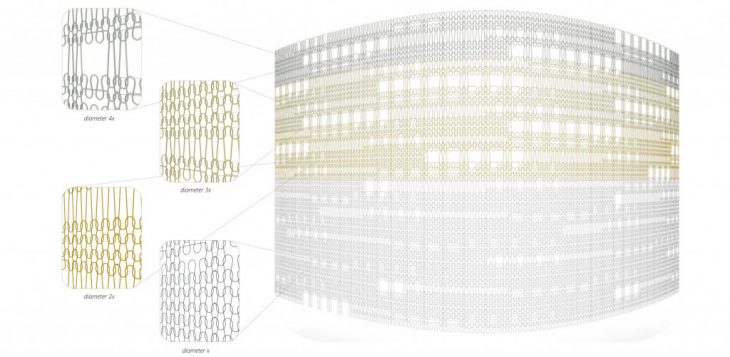

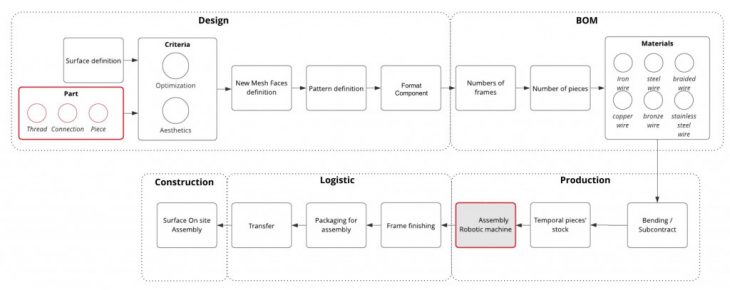

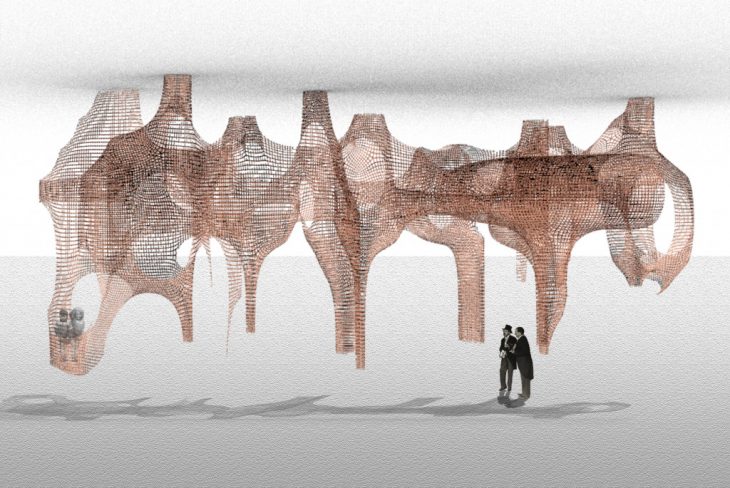

The logic of design starts from a surface, then the definition of the pattern with a specific density and then the extrapolation of the pieces. Afterwards, this result goes to production and then their installation. We defined seven pieces that allows different density to parametrize diverse shapes, as a Lego system.

This system works with gravity and for the same reason hang from an existing structure. The first row is fixed, and the installation of the pieces is from the top to bottom. The robot has the code for a specific pattern to install one of the 7 pieces in the exact place.

Also, the diameter of the wire change from the top to bottom. At the top is bigger to support the structural weight of the other pieces, a slight reduction to the bottom.

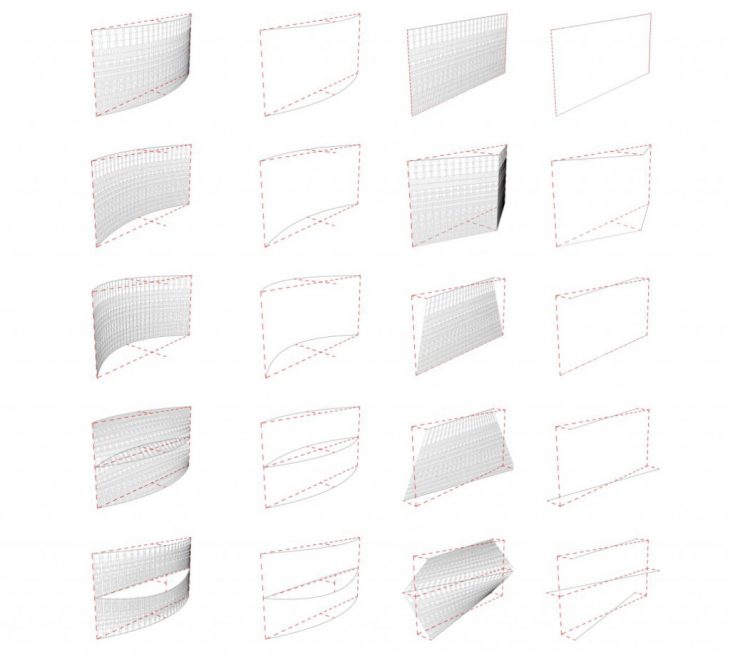

The system has two behavior, the flexibility on the horizontal direction that his union between part is interlocking overlap and in this condition is more rigid. And in their vertical direction that it works like a hinge with the possibility of narrow curves.

X axis growth

X axis growth sequence

X axis and Y axis relation

Y axis growth

Pieces and assembly logic

Study Models

Production

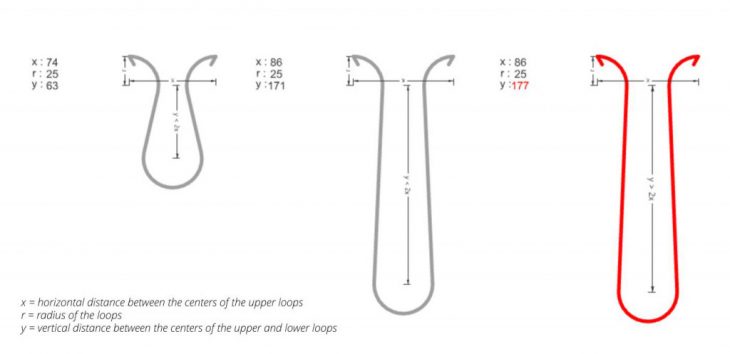

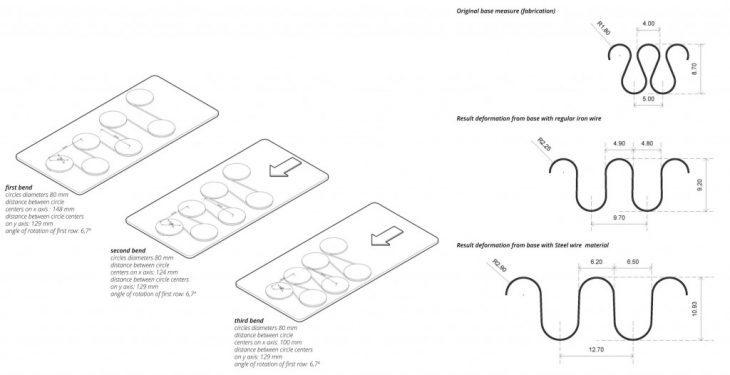

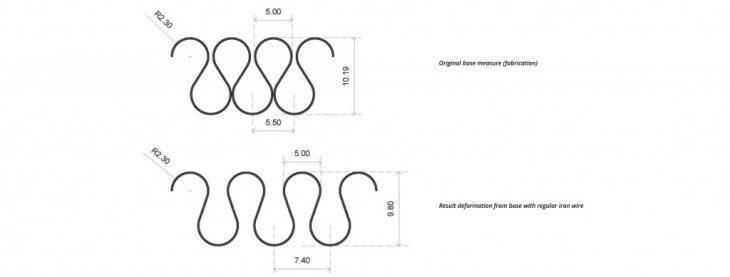

The system has two steps in the process of production. Firstly, bending the wire related to the different pieces, that for the moment is manual. Furthermore, has to consider a deformation in the final result measure. Secondly, the assembly of the pieces over a table where every piece is connected in the same place.

Production process and part deformation in fabrication

Final fabrication pieces

Vertical Flexibility

Deformation on surface

Horizontal Flexibility

Discrete Geometry-Density Pattern /Relation between elements

Pattern Density Analysis

Diameter adjustment related to z axis

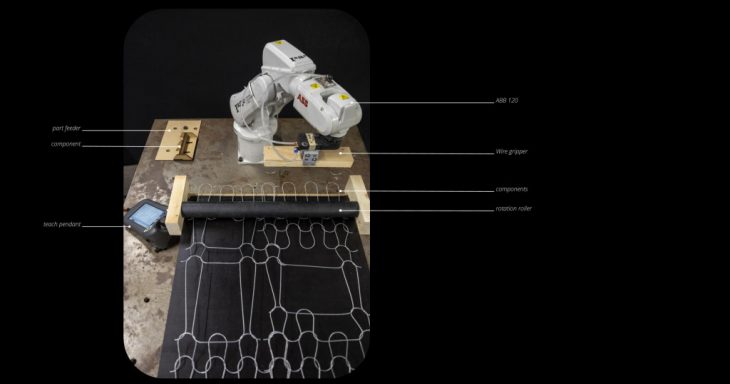

Fabrication / Work Cell

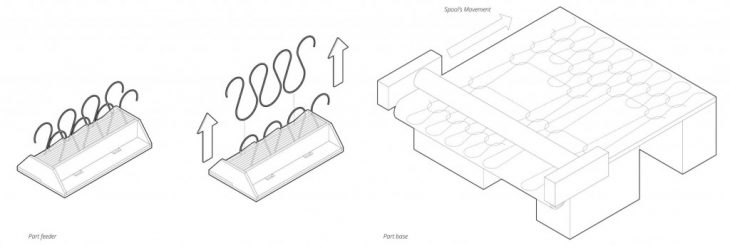

Feeder & Base Support / Horizontal Assembly

To assembly is necessary a feeder support that can be adapted to different quantities and size of the piece, and base support that work at the same time with a rotation roller that has two functions. First, to press the wire mesh to allow the connection of the piece. Secondly, after the installation of one row, it moves the mesh to repeat the process.

Work Cell

Production Flowchart

Where to go next?

Future development /Different Scales and Shapes

Next Steps

The potential of this project has different next steps to develop:

- Develop complex shapes, reducing or increasing the loops to generate double curvature. Analysis of different scale of products and markets.

- Automatic bending

- On-site assembly

- Storage, sorting and selection of the parts with 3D scanning

- Production on factory v/s on-site production

WIRE STRUCTURE // STUDIO I is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at the Master in Robotics and Advanced Construction in 2020/2021 by:

Students: Alberto Browne, Juan E. Ojeda

Faculty: Alexandre Dubor, Raimund Krenmueller

Faculty Assistant: Roberto Vargas