Concept

Direct adoption and integration of current state digital fabrication technologies has been difficult because of the unstructured nature of construction, technical, social, and economic barriers. In this workshop we investigate a hybrid methodology to assemble a set of sticks using XR // Human interaction and the UR10e robots.

But why just think of assembly and construction in a hybrid way but also design using this methodology.

“Balance through design & assembly”

The concept works with using a step-by-step Design + Build process to develop the structure.

Workflow

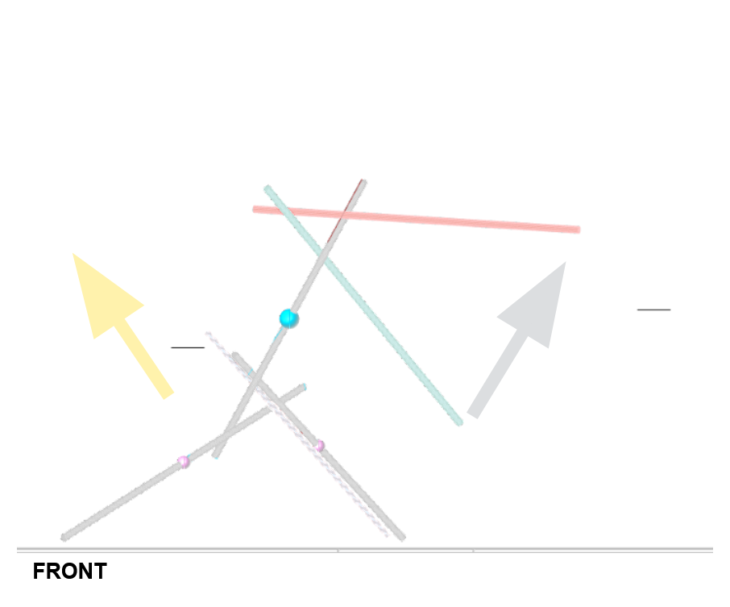

Digital Design Logic

4 base sticks placed by humans

Controllable Parameters:

- 1 element option of placement

- 360 degrees of relative rotation

- 4 iterations of stick flips

- Flipping between human placement and robot placement

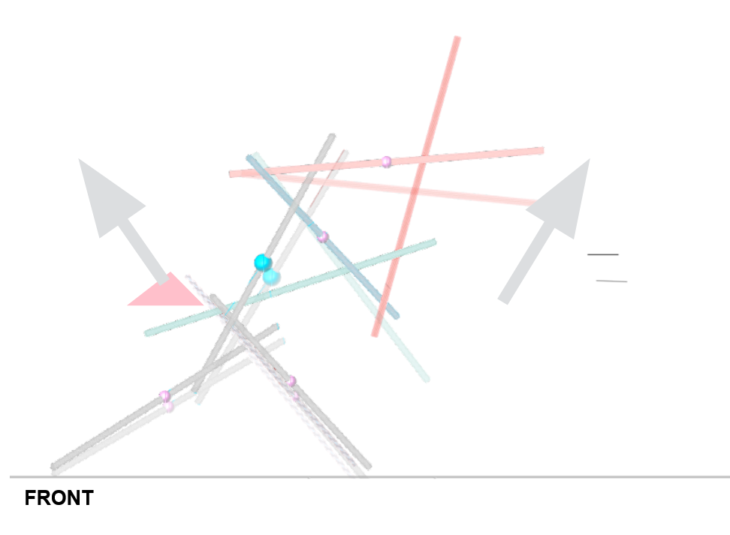

Introduction of bending due to module placed earlier

To mitigate bending:

Controllable Parameters:

- 2 element option of placement

- 360 degrees of relative rotation

- 4 iterations of stick flips

- Flipping between human placement and robot placement

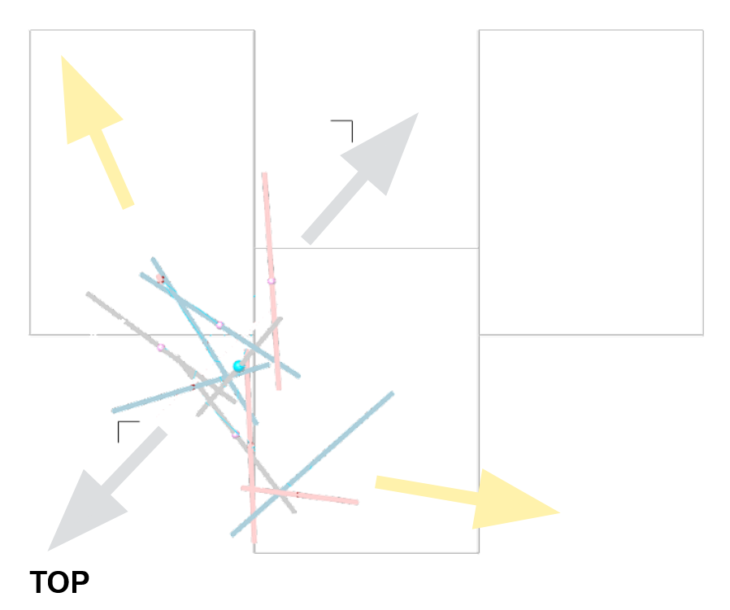

Digital Design Explorations

Iteration 1:

Rotation Angle = Appending 20° at every module

Flipping the sticks typology = 4 options

Iteration 2:

Rotations increase per two pairs by 1.5x

X1 = 10 degrees

Robot See Robot Do is a project by MRAC 01 students Mit Patel, Grace Boyle, Andrea Najera and Tomas Quijano during the Workshop 3.1 seminar of the third term.

IaaC, 23/04/2022

Faculty // Daniela Mitterberger, Lidia Atanasova, Kathrin Dörfler