Context

Wall is the occasion to print thin surfaces and explore the relationship between the geometry and the structural behavior in adobe printing. When addressing structural properties in 3d printing, one should consider two main aspects: the structural integrity during the printing process, that is while the material is wet or uncured, and the one of the printed-dried outcome and the loads it will be subjected to. In order to categorize and frame the research, the focus of the workshop is divided into three structural performances: balance, strength and stiffness. Each of them will be the object of 1,5 day modelling, printing session and structural simulation, organised in the form of 3 catalogues: For each of the three catalogues, need to model 12 simple geometries out of which one will be printed. The results will be tested both physically and digitally: while printed pieces will be structurally tested until breakage, geometries will be also simulated. Scientific measuring documentation of both process will then be used to test the validity of both processes aiming to form a valuable design tools for future design tasks of the OTF program. The workshop is an intense 5 day ?charrette during which there will be printing and documenting session, concluding in the submission of a digital presentation.

Workshop Objectives

1. to model simple lofted geometries. In Rhino and Grasshopper.

2. To produce line axonometric drawings.

3. to produce bottom-up design evolutive catalogues.

4. to 3d print walls with the extruder mounted on the large robotic arm.

5. To develop an understanding of the structural behaviour of wet and dry clay

In pairs, we were given the task to model 2 catalogues of 12 geometries and print one selected geometry from each of the two catalogue (see catalogues for guidelines). Digitally test the catalogue of geometry and physically test the 2 prints and produce a comparative analysis the results.

PART 1: GEOMETRY CATALOGUE

The geometry catalogue was developed based on the following parameters for the Wall Challenge:

- Bounding box: X = 300 mm Y = 150 mm Z = 600mm.

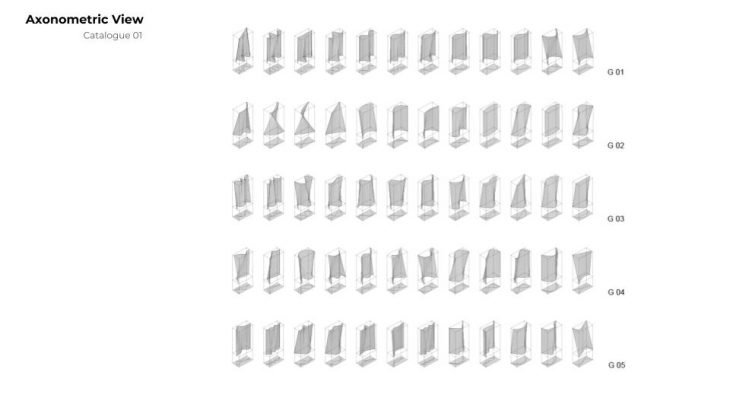

- Catalogue 1: I-line

Make a surface from two planar geometrically continuous curves at Z = 0 and Z = 500mm.

Both curves start and end on the small side of the bounding box.

The maximum surface area of the object is 0.22m2 (= 63 m of printing length) - Catalogue 2: V-shape

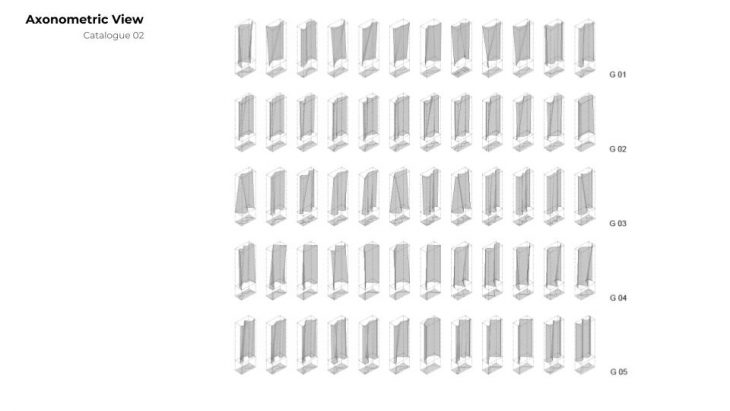

Make a surface from two planar curves with a kink at Z = 0 and Z = 750mm.

The angle is between 45 and 135 degrees.

Both curves start and end on the small side of the bounding box.

The maximum surface area of the object is 0.35m2 (= 100 m of printing length)

Each and every catalogue should start with the most simple geometry, and grow in complexity until the 12th iteration.

Geometry Catalogue 01_geometries generated by 5 different groups 12 iteration each

Geometry Catalogue 01_geometries generated by 5 different groups 12 iteration each

Geometry Catalogue 02_geometries generated by 5 different groups 12 iteration each

PART 2: STRUCTURAL AND GEOMETRICAL ANALYSIS

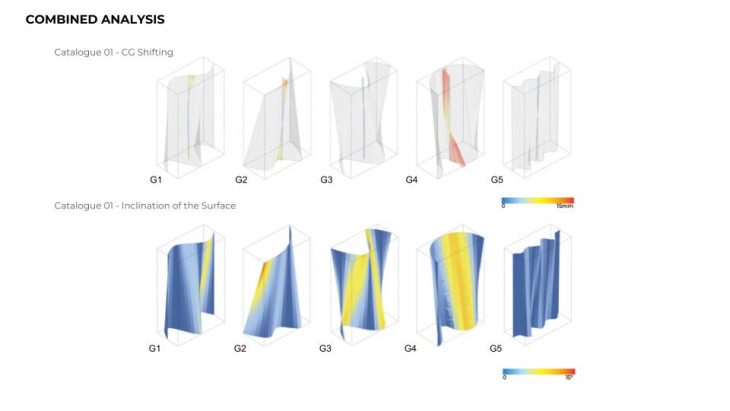

Structural and Geometrical Analysis of Catalogue 01

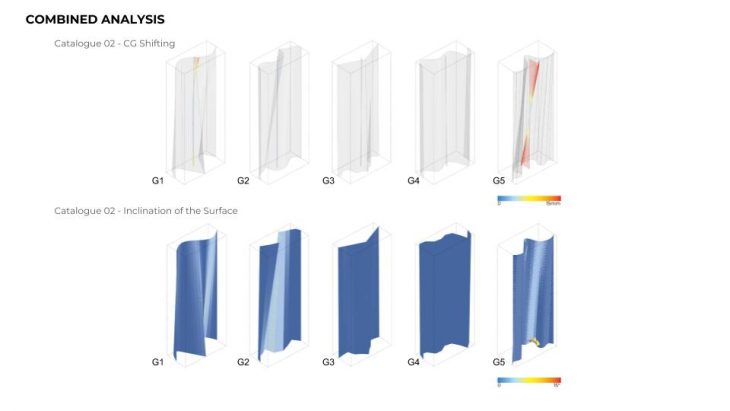

Structural and Geometrical Analysis of Catalogue 02

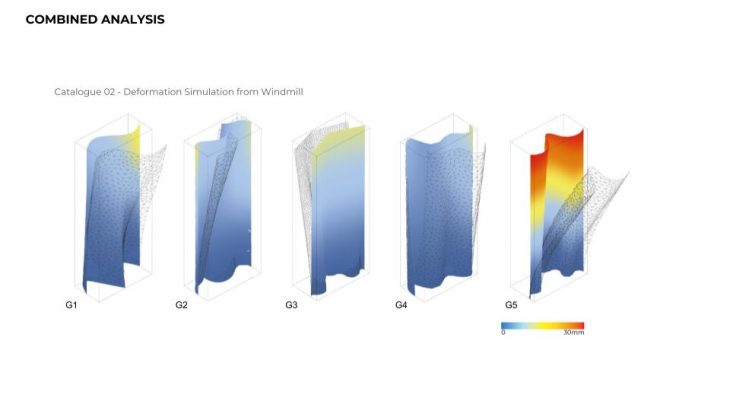

Structural Analysis of Catalogue 02 using AutoCAD plugin developed by Windmill Structural Consultants

PART 3: FABRICATION

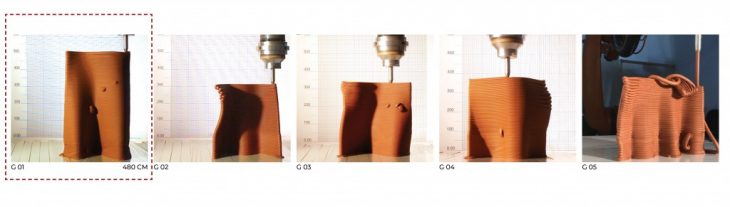

Catalogue 01_Maximum Height Achieved 480 cm

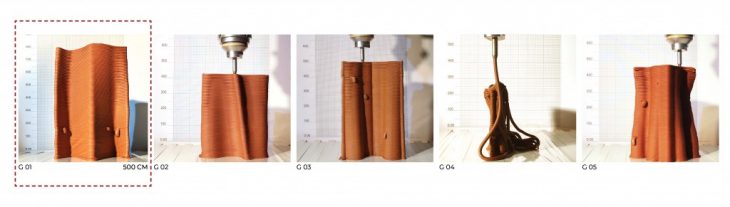

Catalogue 02_Maximum Height Achieved 500 cm

OTF 2018-2019

Faculty : Edouard Cabay | Alexander Dubor | Joaquim Melchor | Kunaljit Chadha

Assitants : Riaz Sheikh | Eugenio Bettucchi

Collaboration : Windmill – structural expert, with digital simulation support; UN-habitat; La – Salle

Team : Ashkan Foroughi | Bhakti Vinod Loonawat | Ipsita Datta | Nusrat Tabassum | Ozgur Cengiz | Pavlina Kriki | Payam Salahinezhad | Shahram Cawsi Randeria | Yi-Fan Liao | Yuchen Chen | Yingxin Du