heXwood – Programming timber laminates

ABSTRACT: Wood is one of the primary materials that man has used to build shelters. Since then it has been exploited as multiple structural and non-structural architectural elements. Various sizes and proportions made it possible to use it for different purposes, from beams to columns or from floors to roofs. Wood’s intrinsic natural composition made it easy to be carved and shaped into any desired form even with primitive tools. Thus it has been used as a material extensively in various industries commercially. Post the industrial revolution, with the emergence of Steel and Concrete the use of timber in architecture and the building industry reduced considerably.

Being a sustainable and long-lasting, renewable (aforestation for building industry), eco- friendly, natural material, wood in recent years has again gained increasing use in high rise structures. Various geometries and forms also have been explored in pavilions and shelters including ICD sewn timber shell, Meteorosensitive Pavilion and the Metropol parasol in Spain, ICD/ITKE research pavilion to name a few. When it comes to timber members, it requires considerably less energy than other building materials in terms of production, transport, assembly, and demolition1. Due to its easily transformable capacity with the help of basic or advanced tools; digital planning and production have opened up new vistas for timber performance and construction.

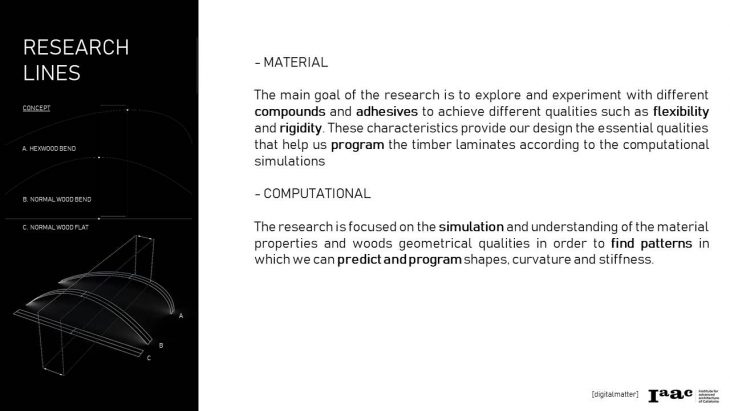

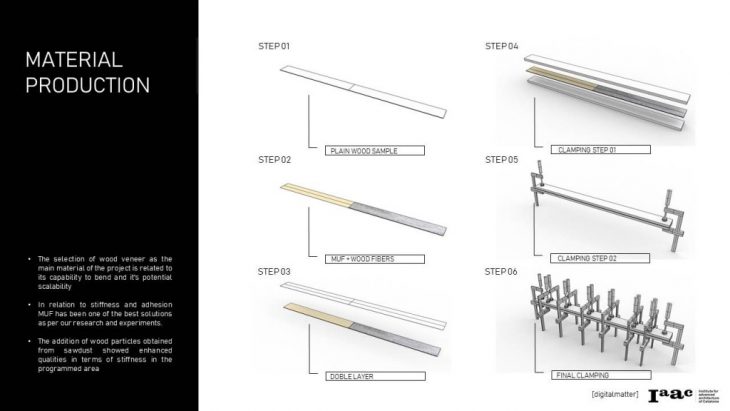

This research project studies and analyses the performance of timber laminates with MUF (melamine urea-formaldehyde) resin and wood particles (sawdust). Timber laminates are pre-programmed by understanding its behavior through simulations with the help of computational tools. Advanced learning and using digital tools will always help to push boundaries for understanding a material better. Its properties to react with different materials, applied forces, physical attributes etc. is crucial to investigate in order to understand their behavior, especially while studying those of new composites.

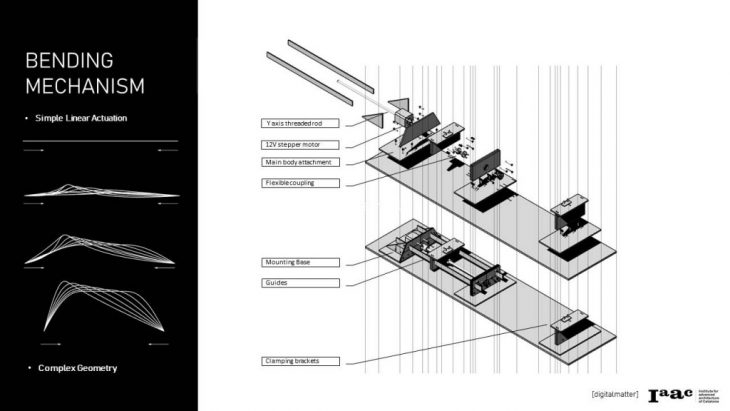

The main focus of this research, study, and experiments is to programme timber laminate composites to achieve varied

geometries that can be designed and controlled in terms of bending and twisting with the help of simple actuation.

Materials | Process | Adhesives

PROCESS

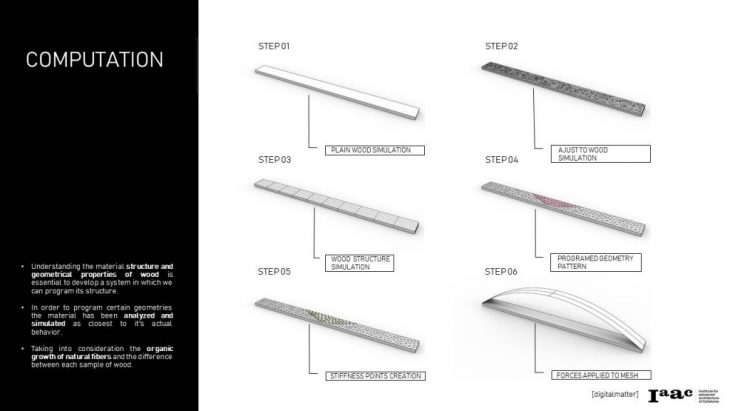

COMPUTATION and SIMULATION

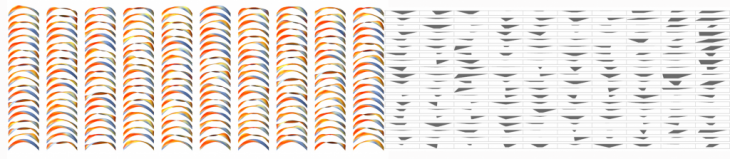

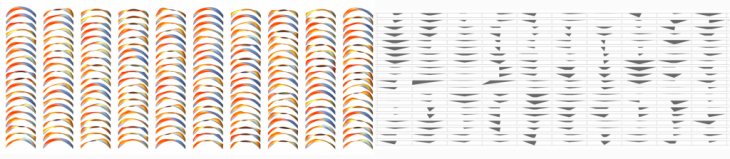

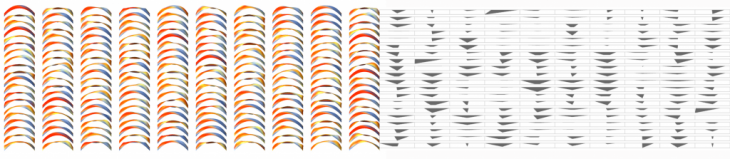

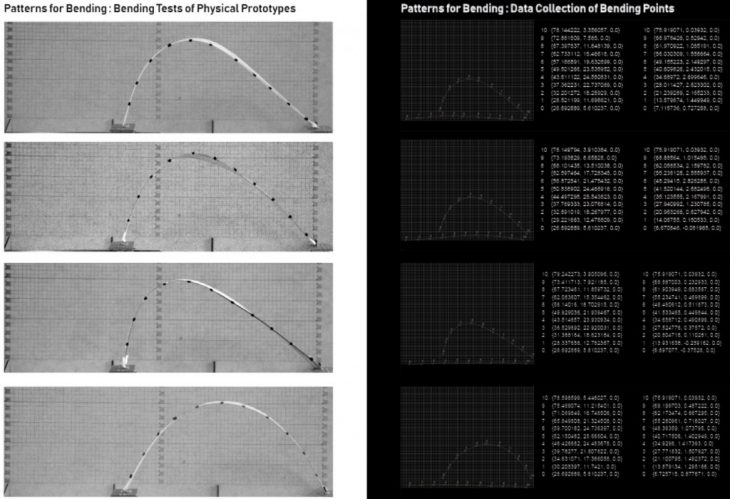

Using simulations to program wood deformation through geometrical patterns.

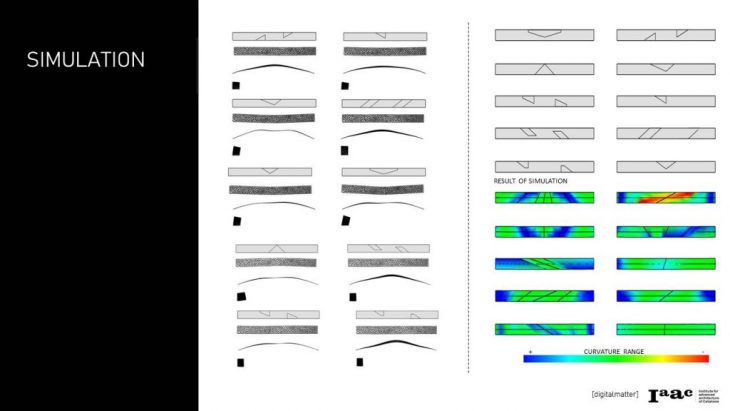

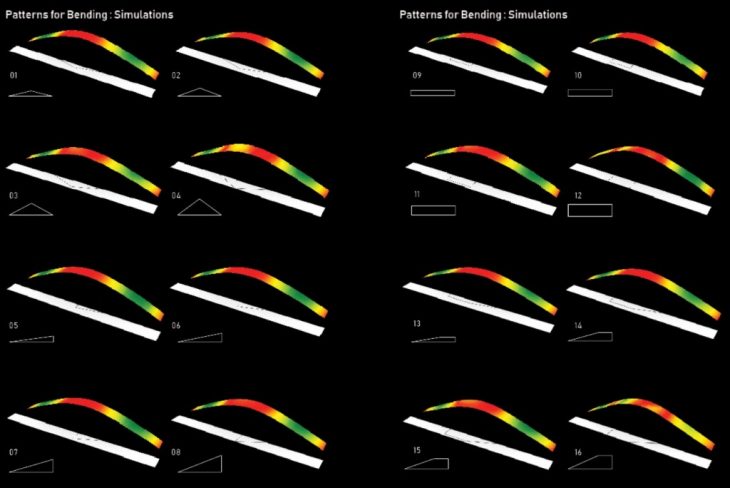

Genetic Algorithm generates a population of iterations using geometrical patterns with the help of random geometrical stiffness patterns in the hexwood strip model.

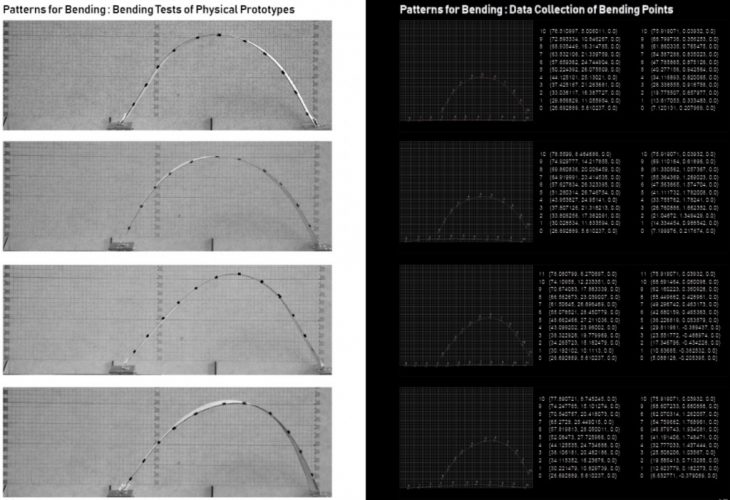

Comparing bending behavior of each sample with critical points analyzing the difference in bending behavior due to the pattern.

Scalability of the Material and Prototypes

One of the advantages of laminating is that it can be scaled in proportions as per requirement. Amount of layers and size may vary. Width and Length ratios are critical as they determine the amount force needed for the actuation and the degree of bending that has to be achieved or is required. While scaling up it is very important to estimate the number of layers needed. In terms of fabrication number of clamps, clamping time increases proportionally and the adhesive mixtures increase proportionately.

PROTOTYPES

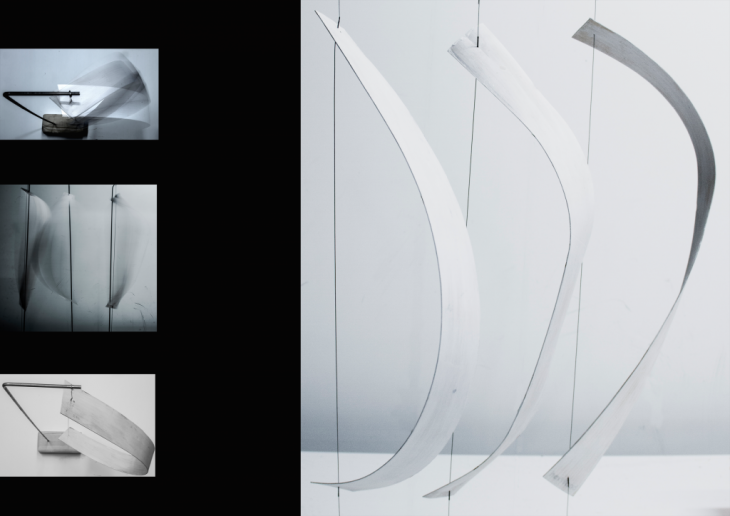

Prototype 1: Bending with Actuation

Prototype 2: Individual Twisting

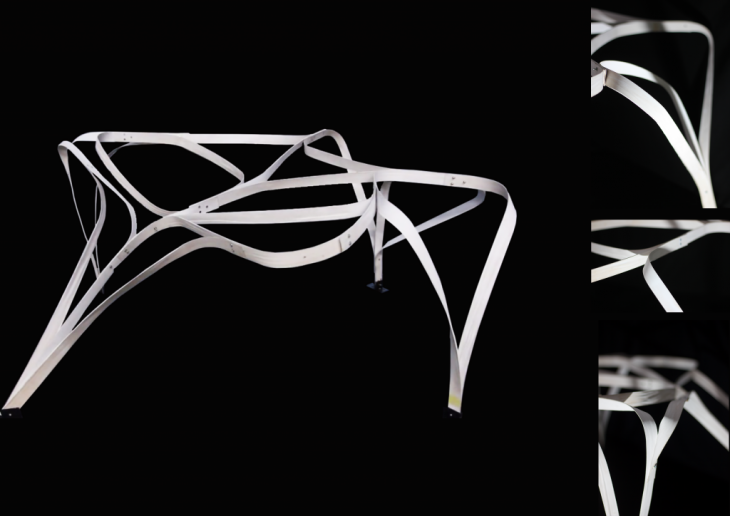

Prototype 3: Freeform Geometry

Future Architectural Vision and Applications

Facade Systems

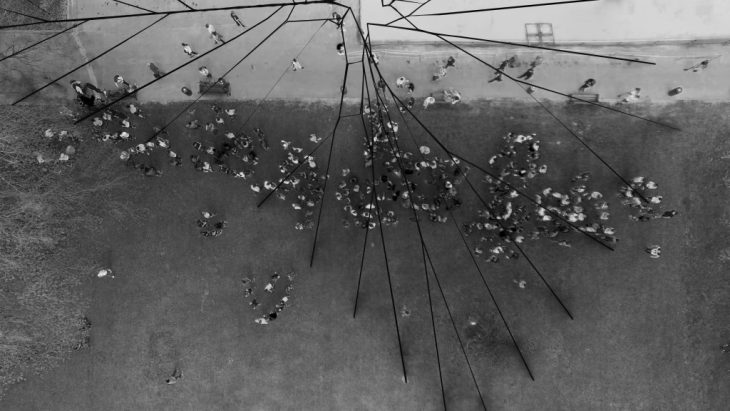

Freeform Structure

Public Auditorium/Pavilion

Open Air Installations

Developed at: MAA01 2017-2018 Master in Advanced Architecture

Faculty Head: Areti Markopoulo

Faculty Assistants: Raimund Kremuller, David Andre Leon Computational Guide: Angelos Chronis