“More than a substance, plastic is the very idea of its infinite transformation; as its everyday name indicates, it is ubiquity made visible. And it is this, in fact, which makes it a miraculous substance: a miracle is always a sudden transformation of nature. Plastic remains impregnated throughout with this wonder: it is less a thing than a trace of movement.” – Roland Barthes

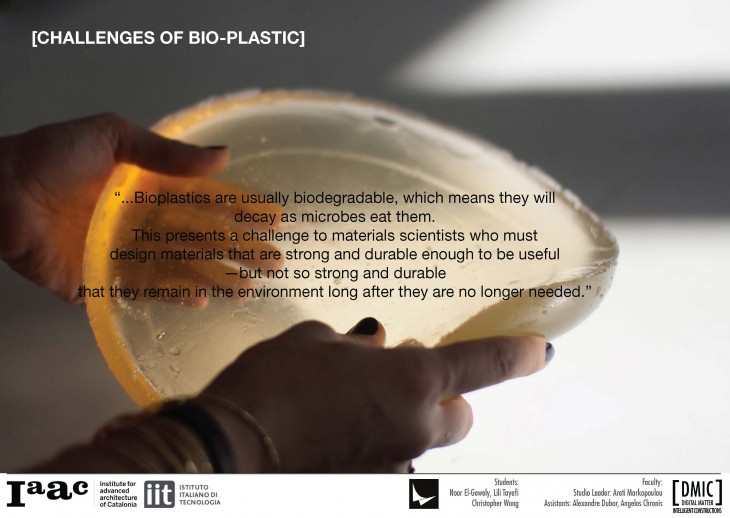

One of the main aims of the [DMIC] Digital Matter Intelligent Construction Research Studio is to investigate the possibility of employing adaptive architecture. During the Space Dynamics workshop led by Manuel Kretzer, we were introduced to the material: Bio-plastic. Unlike plastics derived from fossil fuels, bio-plastic is made from organic compounds, and therefore can be part of the full life-cycle design, also known as the “Cradle-to-cradle” approach.

We were curious to learn more about Bio-plastic, since there are numerous advantages of this material, including the following: Paramentric Material, Affordable, Accessible, Lightweight, Non-toxic, Rigid / Flexible, Transperent, Heat Responsive, Designer / Maker can control, Biodegradable.

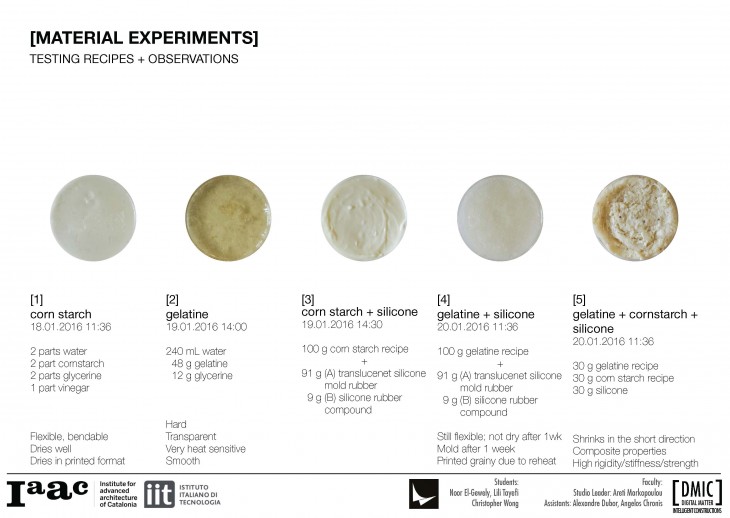

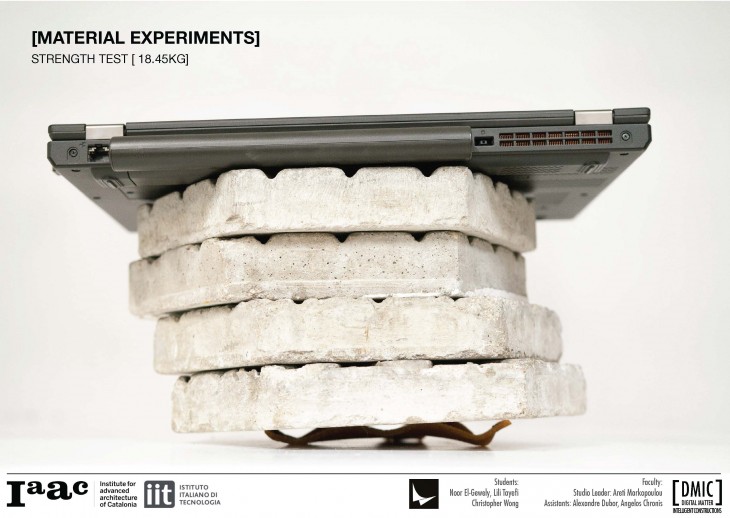

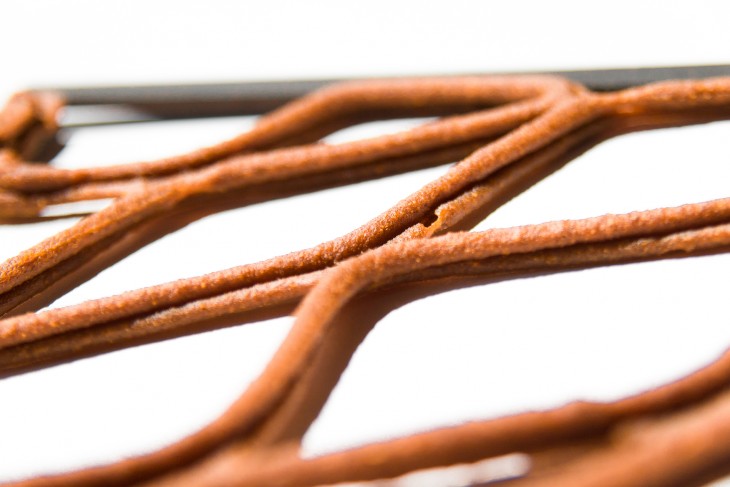

In our early material experiments we were testing various recipes to form our substratum material. Due to its desirable mechanical properties, we proceeded to work with a gelatine based bio-plastic.

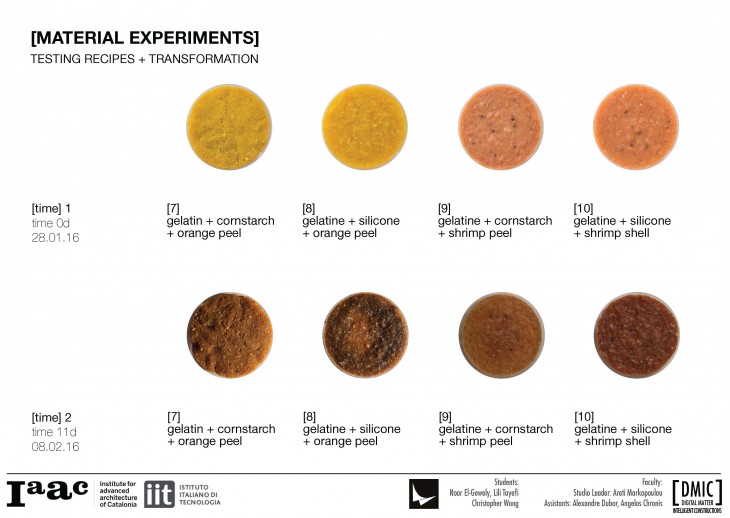

In order to fully take advantage of working with a biodegradable material, and the ethos of reducing, reusing and recycling, we began investigating how we could incorporate food-waste into our bio-plastic. Food-waste is generally perceived as unwanted matter, unless used for compost.

Our aim was to incorporate local food waste from our urban environment, and local context, in order to divert this matter from ending up in landfill. Some of the local produce that initially came to mind was: Orange Peel and Shrimp Peel. Spain is famous for its oranges, and Barcelona for its seafood. In addition to merely up-cycling food-waste, the organic matter would actually provide added beneficial properties to the bio-plastic.

Orange peel contains cellulose, which is an important structural component of the primary cell walls of green plants. It also happens to be the most abundant organic polymer on Earth. Cellulose has a high molecular chain length, or degree of polymerization. This high chain length relates to high tensile strength. Compared to starch, cellulose is more crystalline, meaning it can take higher temperatures before becoming amorphous in water.

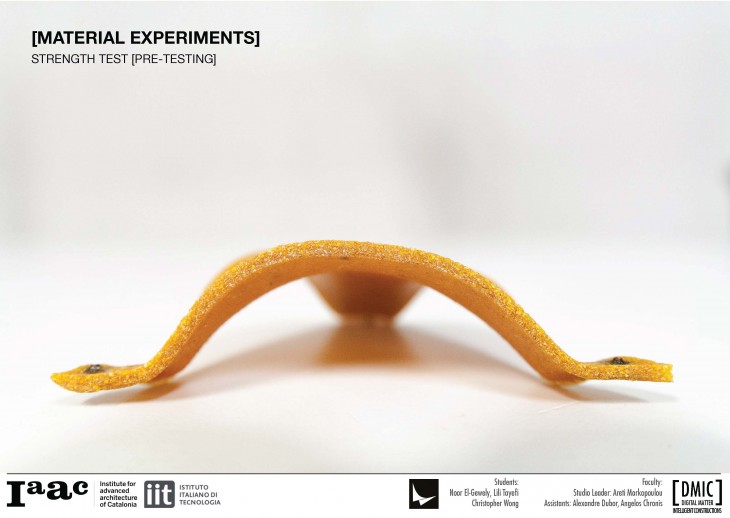

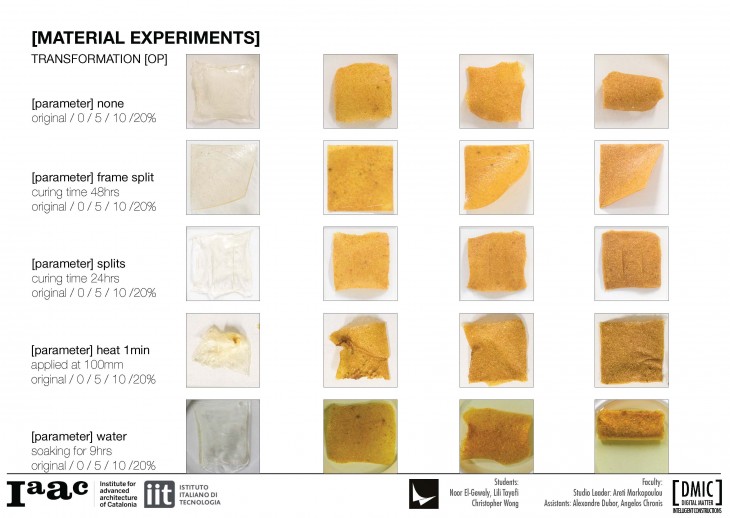

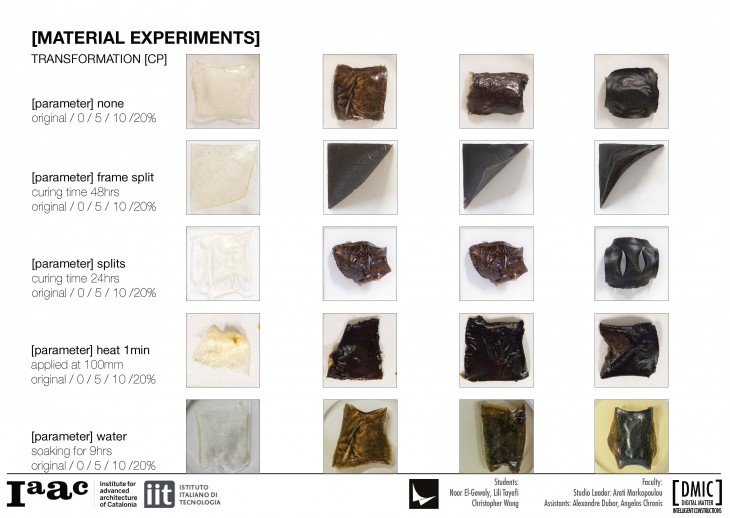

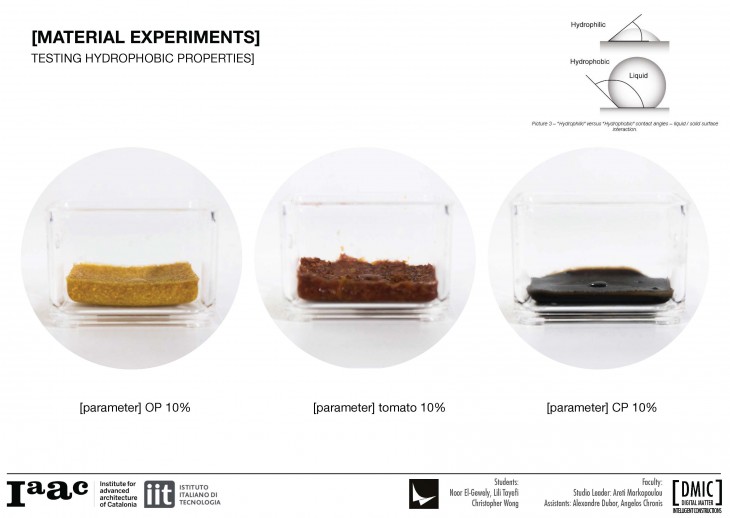

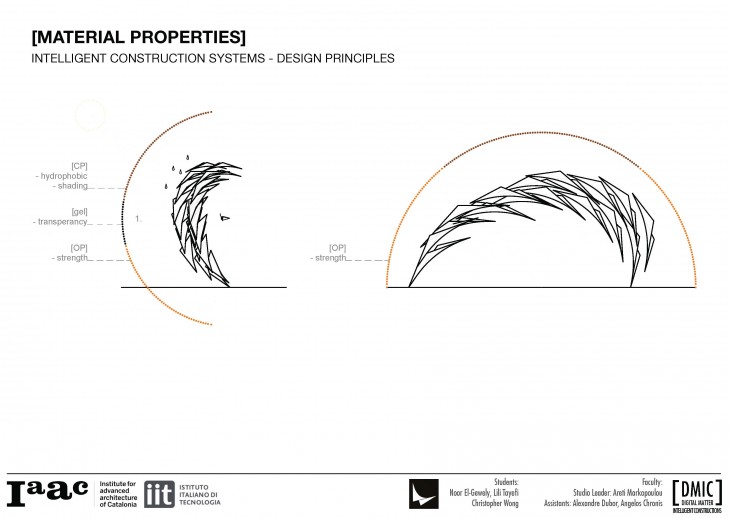

We performed a series of material experiments on our bio-plastic to understand how and to what degree the material would transform when subjected to various strains and stresses.

Some of the lessons learned from our material experiments we learned the Orange peel bio-plastic had improved strength, and higher heat-resistance. While the coffee powder bio-plastic was more hydrophobic.

Another observation that applied to both types of the bio-plastic was, their shrinkage and bend over time. The higher percentage of food-waste we used in the material, the more the material would bend on its own. The input of dehydrating the material would trigger an output of a self-assembly behaviour of the form. This was most dramatic in the coffee based bio-plastic.

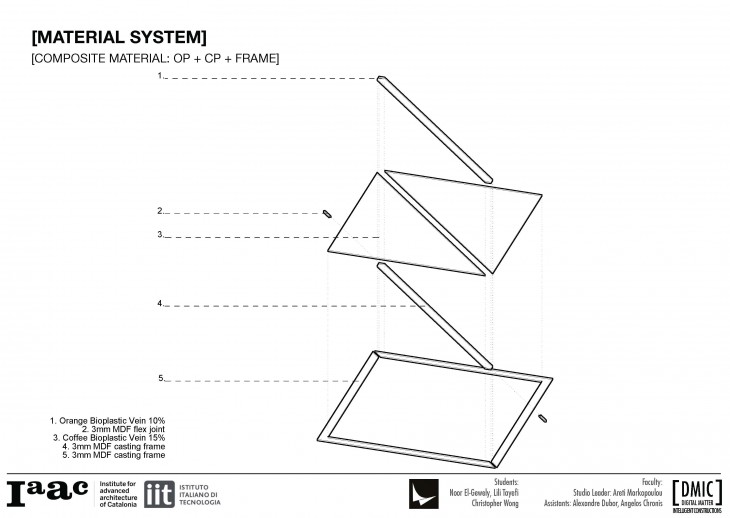

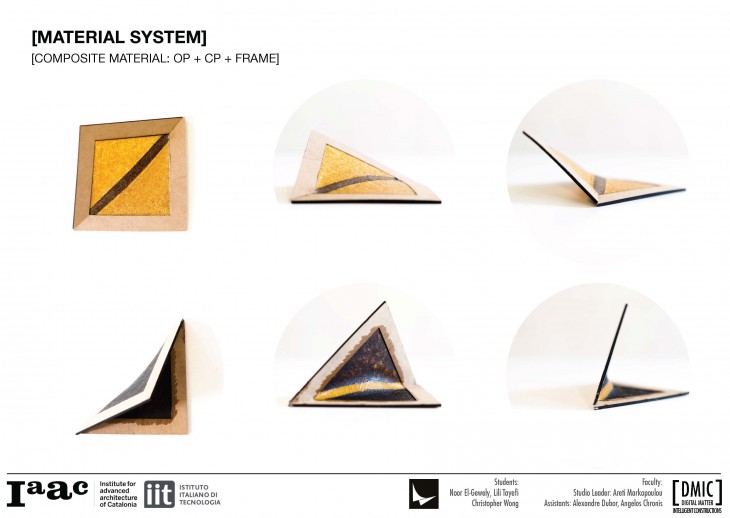

Moving forward, we wanted to develop a material system that combines the different characteristics of both the Orange and Coffee based bio-plastic in order to create a composite material.

How could we begin to control the resultant behaviour of the material based on the geometry and location of the various food-wastes in the composite?

From a design perspective there are different properties that the various types of bio-plastic offer us, based on what type of food-waste we incorporate into it. Due to the ease of production and accessibility of this material, we can tailor the desired parameters to suit, based on our requirements for each project, but also to fine-tune the material performance within any given structure or object.

Although we have chosen to experiment with coffee and orange thus far, we do anticipate that this bio-plastic can be locally re-appropriated to incorporate food-waste which is most abundant at a given geographical location.

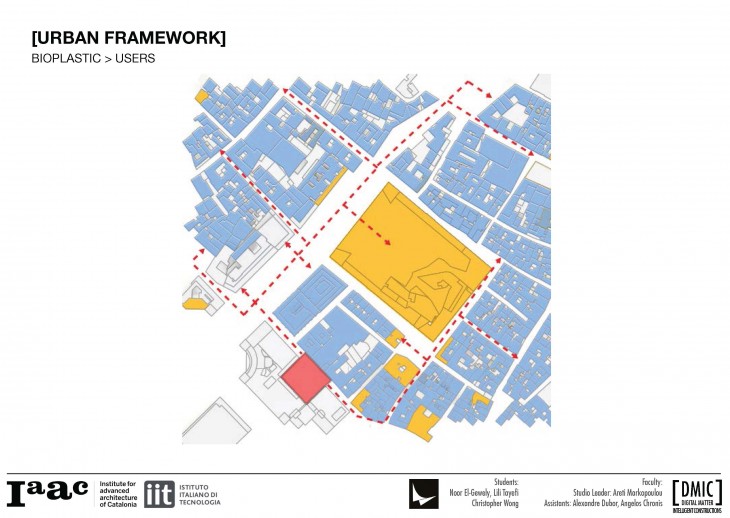

At this stage in the project we are investigating on how we can incorporate the material system of Piel Vivo into our urban cityscape, and participate in the food production and energy cycle of the city. We envision a strategy for the city of the future, where each neighbourhood could have a hub (Shown in Red) to collect food-waste from its surrounding, Food-sources (Yellow) and Residents (Blue). At the food-waste hub the matter is collected and sorted, and the bio-plastic is processed here. The bio-plastic can be made on-demand based on the user requirements, and go directly back for distribution to its local community, reducing the need for transportation.

Our objective for this research is to create an ephemeral architecture with an embedded material intelligence, using low-cost, local materials, which responds to its environment and its users based on their changing needs in contemporary society.

PIEL VIVO/BIO-PLASTICA – Material Explorations is a project of IaaC, Institute for Advanced Architecture of Catalonia, developed at Master in Advanced Architecture in 2015/2016 by:

Students: Noor El-Gewely, Lili Tayefi, Christopher Wong

Faculty: Areti Markopoulou, Alexandre Dubor, Angelos Chronis

With help from: Manuel Kretzer, Athanassia Athanassiou, Ilker Bayer